Manufacturers: Are You Using the Right Printing Supplies for Your Product ID Applications? This is the Best Way to Tell.

Manufacturers can pay quite a high cost for using low quality labels:

- Frequent workflow disruptions and stop-ships. (Did you know that 47% of manufacturers experience costly downtime due to product labeling issues?)

- Premature printhead failure, resulting in preventable disruptions and expenses.

- Fines for labeling non-compliance.

- Slowdowns and waste caused by inventory re-labeling.

- A downgrade in supplier ratings.

- Lost contracts (i.e. lost revenue and profits).

- An increase in IT helpdesk calls (and costs).

That is why every manufacturer should be calling on a Certified Supplies expert to help select the right supplies when implementing a new printing solution or introducing a new product.

Though it is critical to invest in the right printing hardware, software and services, I would argue that buying the right label and ribbon combination warrants even more scrutiny given the impact of these two supplies on manufacturing and supply chain operations. Labels are the means by which products are accurately identified, tracked and monitored for quality control and safety. If your direct product identification (ID) label is inaccurate, falls off at some point in the product’s life or degrades to the point of becoming unreadable, there could be significant consequences. (The list above is just the start.)

However, your engineering, product management and procurement teams probably don’t have a lot of time to invest in learning which label is suitable for every new product you introduce. There are literally thousands of different label types and specifications to consider! To be honest, your teams may not want to spend the time learning about how to select the right label…or ribbon…or other supplies that impact label quality, adherence and durability. That’s okay. That’s why we’re here.

Making the Perfect Match (a Painless Process)

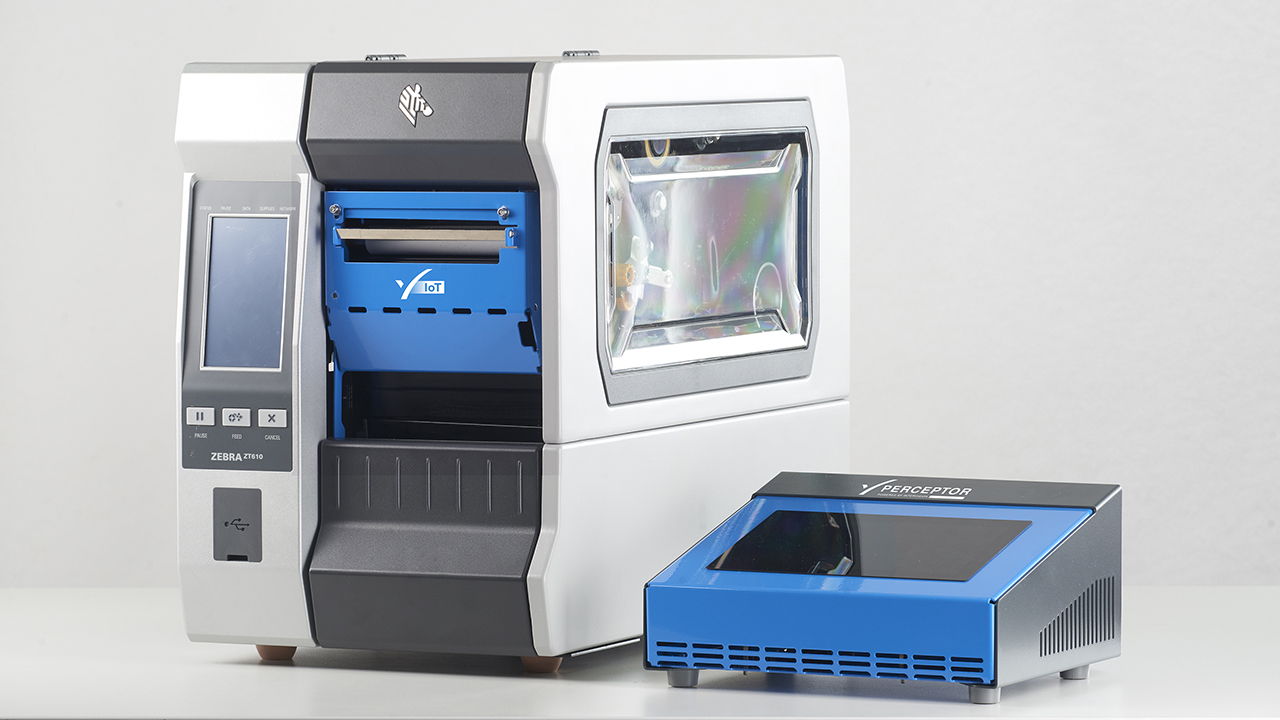

Zebra has been working with customers for over 50 years to design, deploy and refine printing solutions for highly specialized manufacturing labeling applications. We know better than anyone that the printer hardware alone cannot ensure labeling compliance with government or customer requirements. You have to also use labels and ribbons pre-tested and certified for your application in order to keep mission-critical data flowing smoothly and accurately throughout your operation and your supply chain.

If your engineering, product management and procurement teams aren’t already working closely with the Zebra Supplies team to ensure the right product ID labels and printer ribbons are chosen for each manufactured good, then you need to pick up the phone and call us or email us to schedule a consult right now. It can cost tens of thousands of dollars to get a label set up or changed in a bill of materials. You need to get it right the first time.

In fact, our Support team is often called in by organizations to help diagnose and correct “printer” performance issues that, upon further investigation, are discovered to be the result of incorrect supplies selections. In most cases, customers thought they had picked out the right labels for their products (on their own) only to find out quickly, after a lot of time and money was spent on the implementation, that they had not. Or there was a label-ribbon compatibility issue.

Given how many different things must be considered when choosing printing/labeling supplies, it really is best to enlist the help of experts who literally spend all day focused on ensuring …

- Label adherence. Adhesive performance can vary based on the surface type and shape. A Supplies expert can tell you quickly which labels are designed, pre-tested and certified to adhere directly to various materials. In turn, you can be confident that the labels you affix to your products, packages or pallets will remain secured for years.

- Print and label durability. Each thermal material and ribbon on the market today has a different temperature, environmental and chemical resistance, and it can be hard to know a label’s resistance and tolerance to various elements without an expert’s assistance. Fortunately, they’ll be able to help you confirm whether or not the label can endure exposures or contacts with certain chemicals, fluids, radiation, weather elements and more.

- Label compliance with industry and customer compliance requirements. It’s not always easy to confirm which labels are suitable for use on electronics, food and beverage items, medical devices, automobile components and other products where ID labels are required to have special markings. Our Supplies team experts can help you quickly identify which labels are compliant with UL/cUL, FDA 175.105, UID, Globally Harmonized System (GHS), Unique Device Identification (UDI) and GM 14573 mandates, for example.

- Label security. Tamper-evident labels are often demanded by retail customers and others who are prone to losses from counterfeit goods, product contamination or even “clearance fraud”.

- Printer ribbon compatibility with the various product ID labels. Not all thermal ribbons are compatible with all thermal materials. When the ribbon is not compatible with the material, the print easily rubs off or disappears when subjected to abrasion, making the product unidentifiable.

- Label quality and authenticity. This isn’t broadly advertised, but many supplies manufacturers will substitute materials used to produce labels, ribbons and other components, and that can severely impact the quality and performance of your labels. (For the record, Zebra never substitutes materials or ribbon formulations for any reason once we spec them in. You will always get the exact same supplies at the exact same quality. All of our supplies are also ISO 9001:2015 certified via strict quality control processes to ensure reliable, consistent performance.)

- Customization flexibility. It’s important to work with a Supplies manufacturer that can create labels in any size and configuration and, if needed, pre-print static information and branding. Zebra is authorized to pre-print the UL mark. This will help you reduce waste, (again) ensure compliance and reduce labeling-related delays when you’re trying to go to market with new products.

If you have a few minutes, I highly recommend you read this blog post from my colleague Craig Swanson. He goes into a lot of detail about what it takes to choose the right printing solution (and supplies) for your labeling application, including many of the selection criteria I just mentioned.

Remember: any single component of your printing solution can impact the performance of your label, the speed of your labeling-related workflows and the price you pay to comply with the many different regulatory, industry and customer or partner requirements. But if you don’t select the right label and ribbon combination – or supplies that are certified to be of the highest quality – then you run a high risk of experiencing a number of very expensive operational issues within your factories, warehouses and supply chains.

Don’t try to choose your direct product ID labels alone. It’s not worth the risk, especially given how much time and money you’ll save by consulting with Certified Supplies experts who have decades of experience researching, designing and testing labels and other printing solution components for unique product ID applications. Call a trusted supplies provider today to ask for guidance. Even if you think you’re using the right labels and ribbons today, it doesn’t hurt to double check. If you’re already buying the right supplies, great! If not, you’ll be able to make the change you need to protect your reputation with customers, avoid non-compliance penalties, improve your operational efficiency and reduce operating expenses.

###

Did You Know?

Zebra has one of the broadest offerings of pre-tested materials for product ID. We also have relationships with UL and laboratories that can test to specific product labeling requirements, such as those mandated by major automotive, food and beverage, electronics and medical device manufacturers.

Watch the below video then visit this resource page to learn more about how Zebra’s Certified Supplies team can help your team find the right product ID labels and ribbons for your manufacturing applications.

Christine Weber

In 2006, Christine Weber joined Zebra Technologies to market thermal printing supplies in North America and Latin America. During her tenure at Zebra, she has brought supplies to life for enterprises. (There is much more to thermal printing supplies than you think!)

She has deep knowledge of the wide variety of labeling applications across a wide range of enterprises within Retail, Manufacturing, Healthcare and Transportation & Logistics. She is also well-versed in which supplies materials provide the most reliable performance to enable asset intelligence, including facestock, adhesives and ribbons. Along the way, she has driven the marketing of service agreements, managed and professional services, and software in addition to supplies.

Today, Ms. Weber is a thermal printing supplies expert and strategic partner to Zebra’s Global Supplies Product Management and Marketing Teams, in addition to the North America sales team, driving the development of the annual go-to-market plans to achieve supplies growth globally.