Mobile Printing Solves A Problem You Didn’t Know You Had

*This post was written by Kevin Ledversis, Sales Director for Newcastle Systems, a registered Zebra ISV.

###

Did you know you are spending up to twice as much on labor on your receiving dock as you should be? Or that the error rates on your receiving labels could be 10 times what they should be? More importantly, did you know that many of your workers are taking far more footsteps in a day than they need to due to excessive trips to the printer? These are problems that many retailers and 3PLs don’t realize that they have.

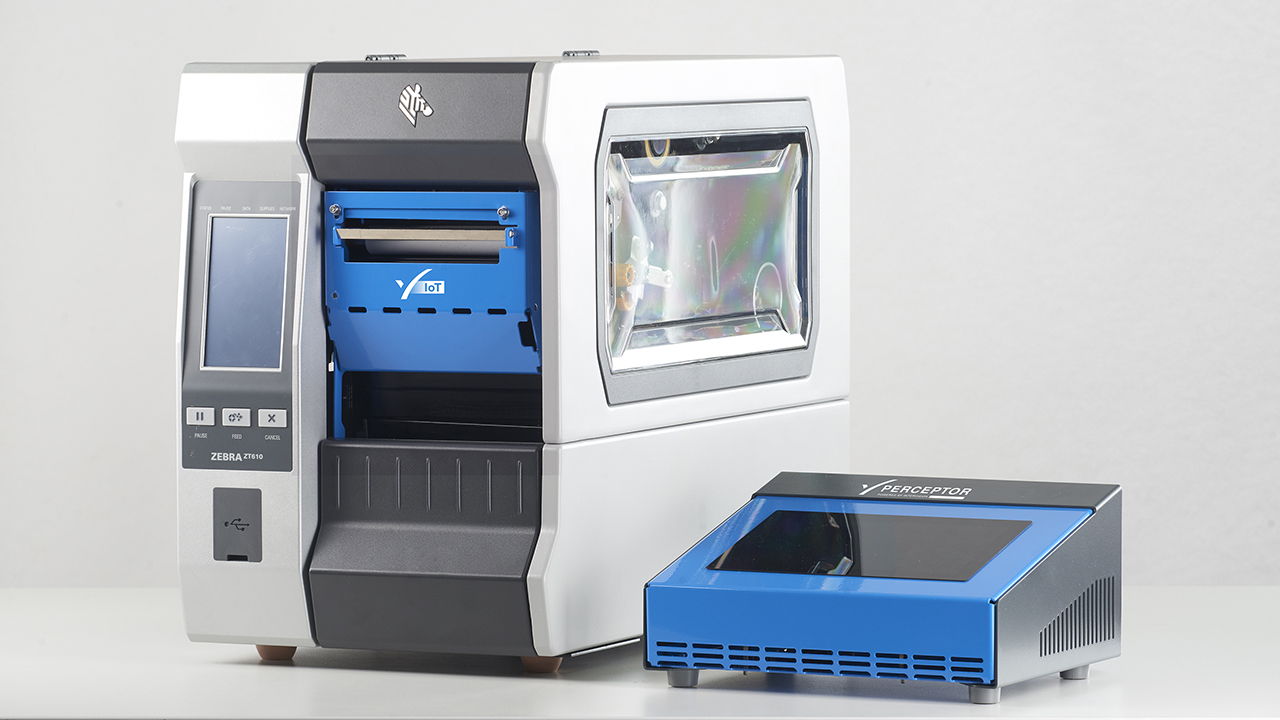

The good news is that these are problems easily solved with transportable printers – or, should I say, a stationary desktop or full-size industrial label printer that can be made mobile.

This is the Easiest Way to Eliminate Printing-Related Footsteps and Errors in Production Facilities, Warehouses and Distribution Centers

While “mobility” has been a mandate for over a decade now, every organization – regardless of industry – can benefit from adopting a “mobile-first mindset” when re-examining their core processes, especially if a label printer is part of the process. Almost any technology device commonly found in the warehouse or on the production floor can “go mobile,” including:

- Thermal Label Printers

- Laptops

- Scanners

- Dimensional Scanners

- RFID Antennae

- Testing Devices

- Scales

- Laser Printers

- Dual Monitors

Workstation solutions such as this one allow you to mount any size printer, up to a full-size industrial label printer, along with a laptop, monitor, scanner and more to instantly mobilize workers and workflows that would otherwise be tethered to a stationary desk. Instead of forcing staff to walk back and forth – which results in lost time, lost inventory and more errors overall – a fully-mobile workstation gives them a print-on-demand capability at the point where they’re processing the pallets.

In other words, the common method of placing printers on a dedicated table, plugged into the ethernet, is an overlooked inefficiency that can be easily remedied for those who want to introduce greater speed and efficiency into high-volume, time-sensitive labeling and logistics applications. Even better, mobilizing a desktop or industrial printer on a powered cart can give you an instant return on investment (ROI).

The ROI of Mobilizing Full-Size Printers for (Just) Receiving

The receiving process is fairly uniform across industries and one of the simplest to measure: by reducing footsteps, you’re automatically speeding up the receiving process.

Consider this: a typical desktop printer prints approximately 1,000 4x6 shipping labels each day. A mid-range industrial printer can typically print 10,000 such labels per day. And a high-performance industrial printer can print shipping labels 24/7. That means that a worker who is able to take a desktop or industrial printer wherever he or she goes can easily process every carton coming off of a 40-foot container. With a laptop, scanner, monitor or other devices mounted on the workstation, troubleshooting, research and other printing tasks are also possible. As the graphic below illustrates, one produce company averaging 18 truckloads received every day saved $22,000 per year in labor just on the receiving dock by deploying a mobile print solution such as the one just described.

Now, you might be wondering if a traditional mobile printer can have a similar impact. Here’s the challenge: most manufacturing facilities, warehouses, distribution centers and even retail locations receive a high volume of pallets and products. That means that a high volume of labels needs to be printed to process each inbound shipment.

While a handheld computer and mobile printer can do the job for low-volume labeling applications, it is likely that associates would have to stop to replenish labels every two to three pallets. Most mobile printers have a relatively small capacity of around 75 labels – nowhere near the volume needed to process most inbound loads.

Related Resource:

Learn more about how Receiving can be transformed in a day with “The Receiving Revolution,” free for download here.

The Unlimited Possibilities

While Receiving tends to be the first application for most users given the immediate productivity gains, mobile printing has measurable benefits in every part of the warehouse.

In fact, our customers quickly get creative in their mobile printing applications as the possibilities become clear:

- Example 1: Inventory Counts

A partner common to both Zebra and Newcastle Systems combined the mobile power capabilities of Newcastle System’s mobile workstation with an RFID antenna that allows the end-user to walk through the warehouse and complete inventory in just 15 minutes. The telescoping pole mounted on the cart can carry multiple antennae and is raised to ensure coverage to the full height of the racking and both sides of the aisle.

- Example 2: Put Away

A large importer with facilities across the U.S. and Canada uses mobile-powered carts equipped with dimensional scanners and scales to measure incoming products and identify the appropriate-sized bins for products requiring irradiation (i.e. spices and medical supplies).

These are just two of the many different ways that “mobile printing” solutions can payoff in manufacturing, warehousing, distribution and retail operations.

Industrial printers have superior Wi-Fi connectivity and management capabilities and can include field upgrades such as RFID encoding and cutter/peeler accessories to accommodate specialized labeling applications. With dozens of different mobile workstation configurations possible – each able to combine different sizes of carts, power packages and accessories – you can really make any device-dependent process mobile to help release bottlenecks and accelerate processes.

Plus, outfitting a dedicated cart with all computing and printing tools required by an associate can facilitate greater social distancing and minimize cross-contamination exposures to COVID-19 and other contagions via widely-shared devices at stationary workstations.

How to Calculate Your Potential ROI for a Full-Sized Mobile Printing Solution

As you’re assessing the ways in which a mobilized industrial or desktop printing solution could benefit your business, ask yourself two questions:

- How many labels per day does this printer create?

- How much walking is involved in applying the labels?

If a stationary printer is expected to produce a high volume of labels every day for tasks that are done in various parts of the warehouse, then “transportable printing” will likely provide a large and immediate impact on your productivity, labor costs and error rates.

###

Editor’s Note:

Contact Zebra or Newcastle Systems to learn more about currently-available industrial and desktop “mobile” printing solutions for your labeling applications.

About the Author:

As Sales Director for Newcastle Systems, Kevin Ledversis helps customers identify where and how process improvements can be made in warehouse operations. Mr. Ledversis has over 20 years of experience within the Automatic Identification and Data Capture (AIDC) industry. Prior to joining Newcastle Systems, he worked in sales for Weber Labeling Solutions, Intermec and Printronix where he developed solutions for complex labeling applications in a variety of verticals such as distribution, manufacturing, healthcare and retail. Mr. Ledversis earned his MBA degree from University of Hartford and a bachelor’s degree from Bryant University.