DS4600 Series for Electronics Manufacturing

Improve productivity and quality control in electronics and light manufacturing

You rely on barcodes to track components and ensure product quality when manufacturing cell phones, computers, televisions, servers and other products. Your workers need to capture barcodes of all sizes and on all surfaces — instantly and flawlessly. And with the DS4600 Series for Electronics Manufacturing, they can. These versatile corded and cordless scanners can capture laser etched direct part marks, high density and low contrast codes, in addition to 4-inch wide barcodes. Designed specifically for electronics and light industrial manufacturing operations, the DS4600-DPE is ideal for clean rooms and other dust-free, water-free environments. A wide decode range enables the capture of direct part marks and high density barcodes, nearer and farther than a general purpose scanner — giving your workers true point-and-shoot simplicity. And Zebra DNA enhances every stage of your scanning journey, from setup and security to management and optimization.

Resets the Bar for Versatility and Performance

Capture It All — From Direct Part Marks to Extra-Wide Barcodes

No matter what type of marks and barcodes are found in your manufacturing operations, you can capture them all with the DS4600-DPE. It easily reads the tiny and dense laser etched DPM codes on plastic and metal subcomponents, as well as ink mark, chemical etch, inkjet mold and thermal spray. And the same imager can read 4-inch wide barcodes found on picklists, carton labels and packages, delivering outstanding value — you can use the same device for multiple applications throughout your operations.

Count On Great Performance to Keep Your Production Line Moving

What makes the DS4608-DPE unique? Its exclusive rear engine design creates more room for a built-in diffuser — providing optimal illumination on a wide variety of surfaces. Indirect lighting enables the capture of marks printed on shiny and reflective surfaces, while direct light provides the bright light needed to successfully read low contrast barcodes and laser-etched marks. And the 800 MHz microprocessor, megapixel sensor and Zebra’s exclusive PRZM Intelligent Imaging technology further improve performance on challenging barcodes.The result? High-confidence scanning for fewer exceptions and workflow disruptions.

Capturing High Density Barcodes Is Easier Than Ever

Direct part marks and high density barcodes can be tough to scan, but not with the DS4600-DPE. This intuitive imager has the widest decode range in its class — enabling workers to position it at a more natural distance to see the barcode they are scanning. The result is point and shoot simplicity for some of the most challenging barcodes.

Haptic and Visual Feedback — Ideal for Noisy Production Lines

On the production line, the traditional beep tone can be hard to hear. That’s why the DS4600-DPE offers multiple feedback modes: haptic/vibration, a good decode LED that’s visible from any position, a traditional beep tone, plus Zebra’s Direct Decode Indicator that projects the illumination on the barcode. No matter how noisy your environment might be, workers instantly know they are about to utilize the right component — there’s no need to stop and verify that a scan was completed.

Boost manufacturing capacity and error-proof the production line with the DS4600-DPE — the high performance imager purpose-built for electronics and light manufacturing.

For more information, visit www.zebra.com/ds4600dpe

Day-in, Day-out Dependability on the Production Line

Your production line doesn’t stop, and neither does the DS4600-DPE. It’s engineered for durability, inside and out. IP52 sealing protects against spills, while an exclusive double-sealed optical system protects the critical optical components from dust and liquid — ensuring that the ‘eye’ of the scanner always captures the sharpest possible barcode image for fast and reliable decoding. The recessed scan window protects against smudges, dirt and scratches, which can impact performance. And the scanner is built to survive multiple 6 ft (1.8m) drops to concrete and 2,000 tumbles in our punishing tumble test.

On-the-Fly Switching Between Handheld and Hands-Free

Simply place the scanner in the optional presentation stand or presentation cradle to automatically switch to hands-free mode; pick up the scanner for handheld mode — no setting changes required.

Do More With Productivity-Enhancing Innovation

Streamline Workflows with GS1 Label Parsing

With Label Parse+, the DS4600-DPE can instantly capture and parse GS1 label barcode data, enabling workers to capture expiration dates, lot number, manufacturing location and more.

Capture Multiple Barcodes With One Press of the Scan Trigger

With Multi-Code Data Formatting (MDF), the DS4600-DPE can scan multiple barcodes with a single trigger pull and transmit only the barcodes you need, in the order your application expects. You get superior versatility and value — the same imager that can read small dense codes on the production line can also read multiple paper codes on packages in the receiving area.

Single Out One Barcode From Many

With Zebra’s Preferred Symbol, the DS4600-DPE can capture and output only the preferred barcode, so workers no longer have to waste time physically covering nearby barcodes before scanning.

A Better Cordless Experience With Zebra

Full-Shift Power your Workers Can Count On

The cordless DS4678-DPE supports more than 50,000 scans in a single charge — that’s more than 13 hours of continuous scanning.

Choice of Standard and Presentation Cradles

The Presentation Cradle provides convenient hands-free scanning and charges the battery during use. The Standard Cradle can sit on a desktop or be mounted on a wall. And Zebra’s Connect+ Contact technology assures reliable, corrosion-free charging over the life of the scanner.

Keep Track of Your Cordless Imagers

With Virtual Tether, you won’t have to worry about downtime caused when a cordless imager is misplaced in the receiving area or in a picking bin. Both the imager and cradle alert when a scanner is taken beyond its range or left out of the cradle for a predefined length of time. That means devices are always where they should be, fully charged and ready for use.

Eliminate Wireless Network Interference with Wi-Fi Friendly Mode

Zebra’s exclusive Wi-Fi Friendly Mode ensures that cordless imagers won’t interfere and disrupt your Wi-Fi network.

Industry-Preferred Management Tools

Effortless Deployment

The DS4600-DPE couldn’t be easier to setup. Right out of the box, the imager is configured for the applications you use every day, while auto-host detect cables automatically select the right host interface — just plug in the scanner and you’re ready to go.

Up-To-The-Minute Insight Into Every Aspect of Your Imagers

Remote Diagnostics automate the recording of scanner asset information, health and statistics, parameter settings and barcode data — giving you the information needed for event verification, blockchain traceability, pilot site ROI generation, troubleshooting and predictive fleet-wide trend analysis.

Make Data-driven Decisions Informed by Your Imagers

Do more with your DS4600-DPE devices with Zebra’s IoT Connector, a fully automated real-time data collection tool that routes data from your scanners into your preferred IoT endpoint. The result? You can mine the data and get the insights needed to make decisions in real time.

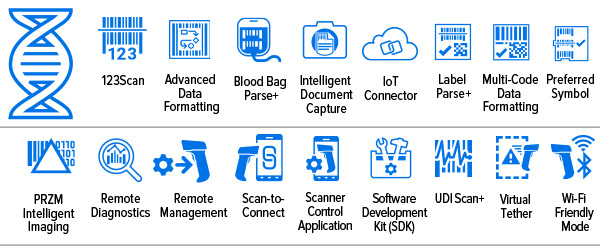

Zebra DNA — Set Up. Secure. Manage. Optimize.

With more than 50 years of field-proven innovation, Zebra knows the scanning journey better than other providers. That’s why we’ve engineered Zebra DNA into all of our scanners. This suite of software tools provides constant visibility, increases uptime and gives you the flexibility to respond to changing needs. For example, 123Scan simplifies every step of deploying your scanners. With Advanced Data Formatting, you can easily create scanner data formatting rules to optimize your workflows and solve business problems. Powerful complimentary management software enables easy remote management. And much more.

Specifications

Physical Characteristics

Dimensions

| Corded DS4608-DPE: 6.5 in H x 2.6 in W x 3.9 in D 16.5cm H x 6.7cm W x 9.8cm D Cordless DS4678-DPE: 6.6 in H x 2.6 in W x 4.2 in D 16.8cm H x 6.6cm W x 10.7cm D Standard Cradle: 2.8 in H x 3.3 in W x 8.3 in D 7.1cm H x 8.4cm W x 21.1cm D Presentation Cradle: 2.8 in H x 3.3 in W x 8.3 in D 7.1cm H x 8.4cm W x 21.1cm D |

| Weight | Corded: 5.7 oz (161.9g) Cordless: 7.9 oz (225g) Standard Cradle: 7.1 oz (201.3g) Presentation Cradle: 6.5 oz (184.3g) |

| Input Voltage Range | Corded: 4.5 to 5.5 VDC Host Powered; 4.5 to 5.5 VDC External Power Supply Standard/Presentation Cradle: 4.7 to 5.5 VDC Host Powered; 10.8 to 13.2 VDC External Power Supply |

| Operating Current at Nominal Voltage (5.0V) | Corded: 340 mA (typical) Standard/Presentation Cradle: 470 mA (typical) Standard USB; 743mA (typical) 12V |

| Standby Current (Idle) at Nominal Voltage (5.0V) | Corded: 150 mA (typical) |

| Color | Twilight Black |

| Supported Host Interfaces | USB, RS232, TGCS (IBM) 46XX over RS485 |

| Keyboard Support | Supports over 90 international keyboards |

| User Indicators | Direct Decode Indicator, Good Decode LEDs, Rear view LEDs, Beeper (adjustable tone and volume), haptic/vibration |

Performance Characteristics

| Light Source | Aiming Pattern: circular 528nm true green LED |

| Illumination | (2) warm white LEDs |

| Imager Field of View | 34° H x 21.6° V nominal |

| Image Sensor | 1280 x 800 pixels |

| Minimum Print Contrast | 15% minimum reflective difference |

| Skew/Pitch/Roll Tolerance | +/- 60°, +/- 60°, 0°–360° |

Imaging Characteristics

| Graphics Format Support | Images can be exported as Bitmap, JPEG or TIFF |

Symbol Decode Capability1

| 1D | Code 39, Code 128, Code 93, Codabar/NW7, Code 11, MSI Plessey, UPC/EAN, I 2 of 5, Korean 3 of 5, GS1 DataBar, Base 32 (Italian Pharma) |

| 2D | PDF417, Micro PDF417, Composite Codes, TLC-39, Aztec, DataMatrix, DotCode, Dotted DataMatrix, MaxiCode, QR Code, Micro QR, Han Xin, Postal Codes, SecurPharm |

| Minimum Element Resolution | Code 39 – 2.0 mil DataMatrix – 4.0 mil |

User Environment

| Operating Temp. | +32.0F to +122.0F (0.0C to +50.0C) |

| Storage Temp. | -40.0F to +158.0F (-40.0C to +70.0C) |

| Humidity | 5% to 95% RH, non-condensing |

| Drop Specification | Designed to withstand multiple drops at 6.0 ft (1.8m) to concrete |

| Tumble Specification | Designed to withstand 2,000 tumbles in 1.5 ft (0.5m) tumbler |

| Sealing | IP52 |

| ESD | Scanner/Standard Cradle/Presentation Cradle: ESD per EN61000-4-2, +/-15 KV Air, +/-8 KV Direct, +/-8 KV Indirect |

| Ambient Light Immunity | 0 to 10,000 foot candles/0 to 107,000 Lux |

Radio Specifications (DS4678-DPE)

| Bluetooth Radio | Standard Bluetooth Version 5.2 with BLE: Class 1 330ft (100m) and Class 2 33ft (10m), Serial Port and HID Profiles; adjustable power: Class 1: output power adjustable down from 2dbm in 8 steps; Class 2: output power adjustable down from 0dbm in 8 steps |

Battery (DS4678-DPE)

Battery | Type: Li-Ion with asset reporting Capacity: 2,500 mAh Number of scans from full charge: 50,0003 Charge times from empty to full: 2 hours 15 minutes over external 12V 4 hours 30 minutes over external 5V 3 hours over BC1.2 USB 7 hours 45 minutes over standard USB |

Decode Ranges (Typical)2

Symbology/Resolution | Near/Far |

| Code 128: 2 mil | 0.3 in to 2.3 in (0.8cm to 5.8cm) |

| Code 128: 3 mil | 0 in to 3.5 in (0cm to 8.8cm) |

| Code 128: 15 mil | 4.2 in to 8.6 in (10.7cm to 21.8cm) |

| Code 39: 2 mil | 0.2 in to 3.0 in (0.5cm to 7.6cm) |

| Code 39: 3 mil | 0 in to 3.8 in (0cm to 9.6cm) |

| Code 39: 5 mil | 0 in to 5.2 in (0cm to 13.2cm) |

| PDF 417: 4 mil | 0 in to 3.3 in (0cm to 8.4cm) |

| PDF 417: 5 mil | 0 in to 3.8 in (0cm to 9.6cm) |

| PDF 417: 6.6 mil | 0 in to 4.5 in (0cm to 11.4cm) |

| UPC: 13 mil (100%) | 0 in to 8.5 in (0cm to 21.5cm) |

| DataMatrix: 4 mil | 0.2 in to 2.8 in (0.5cm to 7.1cm) |

| DataMatrix: 5 mil | 0 in to 3.4 in (0cm to 8.6cm) |

| DataMatrix: 10 mil | 0 in to 4.8 in (0cm to 12.2cm) |

| QR Code: 10 mil | 0 in to 4.5 in (0cm to 11.4cm) |

Utilities and Maintenance

| 123Scan | Programs scanner parameters, upgrades firmware, provides scanned barcode data and prints reports. www.zebra.com/123Scan |

| Scanner SDK | Generates a fully-featured scanner application, including documentation, drivers, test utilities and sample source code. www.zebra.com/windowssdk |

| Scanner Management Service (SMS) | Remotely manages your Zebra scanner and queries its asset information. www.zebra.com/sms |

Regulatory

| Environmental | 2011/65/EU and EN 50581:2012 and EN IEC 63000:2018 |

| Electrical Safety | UL 60950-1, second edition, CAN/CSA-C22.2 No. 60950-1-07. EN 60950-1:2006/A2:2013 IEC 60950-1:2005/A2:2013 IEC 62368-1 (ed.2); EN 62368-1:2014 |

| LED Safety | IEC 62471:2006 (Ed.1.0); EN 62471:2008 |

| EMI/RFI | FCC: 47 CFR Part 15, Subpart B, Class B ICES-003 Issue 6, Class B EN 55032, Class B EN 55024 EN 55035 EN 60601-1-2:2015, IEC 60601-1-2:2014 |

Accessories

| Gooseneck Intellistand, Cup, Standard Cradle, Presentation Cradle |

Warranty

| Subject to the terms of Zebra’s hardware warranty statement, the DS4678 and the CR8178 are warranted against defects in workmanship and materials for a period of three years from the date of shipment. The DS4608 is warranted against defects in workmanship and materials for a period of five years from the date of shipment. For the complete Zebra hardware product warranty statement, please visit: www.zebra.com/warranty |

Recommended Services

| Zebra OneCare Select; Zebra OneCare Essential; Zebra OneCare Battery Maintenance |

Footnotes

1. Refer to Product Reference Guide for complete list of symbologies. Specifications are subject to change without notice. |

Zebra DNA

| Zebra DNA is a suite of highly intelligent firmware, software, utilities and apps exclusively engineered to ensure maximum performance from every Zebra scanner. For more information, please visit www.zebra.com/zebradna |

Markets and Applications

Electronics and Light Industrial Manufacturing

- Product assembly

- Traceability

- Quality assurance

- Inventory and materials management

- Replenishment

- Picking

The Zebra wordmark and logo are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2025 Zebra Technologies Corp. and/or its affiliates.

06/04/2024 HTML