Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimise workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

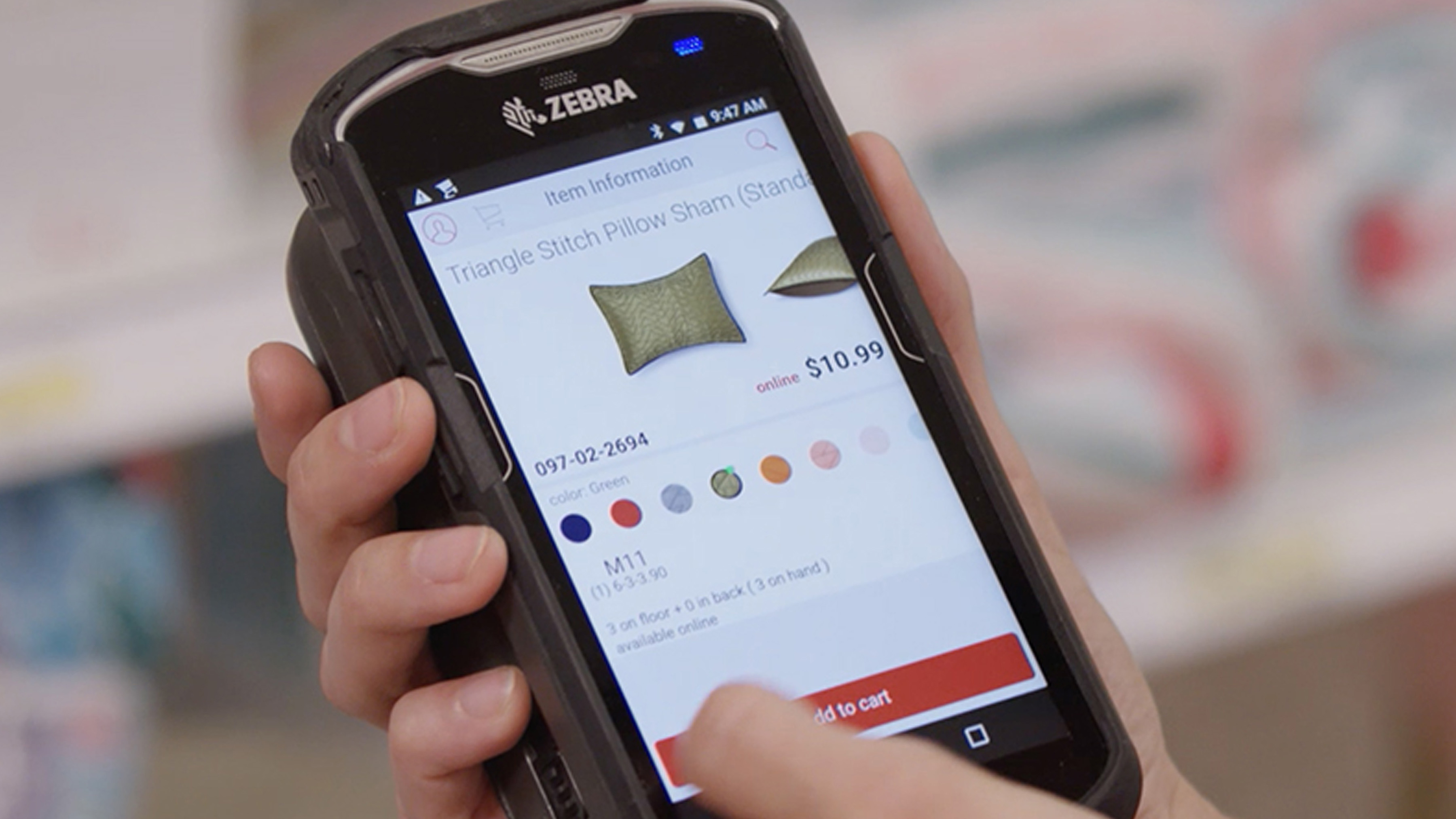

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customise your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Zebra's location technologies provide real-time tracking for your organisation to better manage and optimise your critical assets and create more efficient workflows.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

The everything you need to rapidly and cost effectively develop high-performance AI vision applications on Zebra mobile computers.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labour costs low, your talent happy and your organisation compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximising IT resources and minimising down time.

Make the most of every stage of your scanning journey from deployment to optimisation. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customisation starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximise productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

What Is a Touch Panel?

Touch panels greatly contribute to the perception of quality and overall usability of a mobile device. Touch panels are a primary means by which users interact with their mobile computers, controlling everything from navigation to input. Therefore, the responsiveness, sensitivity, and interface design of these touch panels can greatly impact a user's experience with the device, affecting how they perceive its quality and usability. Through persistent innovation, these components have grown in capability and complexity.

Many touch panel manufacturers are committed to seeking out new technologies and improving existing ones. This commitment aims to meet the growing needs of customers in new and innovative applications and environments.

Types of Touch Panels

Long before the mass deployment of consumer smartphones, the use of touch panels became popular to control enterprise digital assistants (EDAs).

Referred to as “touch panels”, “touch screens”, or “digitizers”, these components are all part of the group of sensors that translate the position of an input in a physical reference space to an input in a digital space.

These sensors are often transparent and integrated with LCD displays to create the touch user interface (touch UI) now present everywhere from automobiles to home thermostats. The types of touch panels present in today’s products can be separated into two groups: resistive and capacitive.

1. Resistive Touch Panels

Resistive touch sensing technology has been established for a relatively long time. This type of touch panel is commonly used for its simplicity of construction, durability, and environmental flexibility.

As the name would suggest, a resistive touch panel senses position by converting physical compression of the touch panel to changes in resistivity.

Design and Functionality of Resistive Touch Panels

A resistive touch panel is constructed from two films, which are separated by an air gap. Both films have electrically conductive surfaces that face each other.

Each of the conductive surfaces detects position in one orientation; for example, the top film may detect vertical position and the bottom film may detect horizontal position. When an input force is applied to the touch panel, the top film collapses inward beyond the air gap to make a physical contact with the bottom conductive surface.

The resulting electrical connection changes the resistance value across both the upper and lower conductive surfaces. A microcontroller within the device measures this new resistance value as a change in voltage, which corresponds to a new vertical and horizontal position. The measurement of the upper and lower conductive surfaces occurs many times a second to track input, such as a stylus, as it is moved across the touch panel.

Resistive Touch Panel Limitations

Micro-Cracking and Mechanical Wear

Since a resistive touch panel relies on physical movement of the top film to create an electrical connection, this type of touch panel is susceptible to mechanical wear. This mechanical wear occurs because every physical movement of the top film causes small micro-cracks in the conductive surface.

Once these micro-cracks grow large enough to disrupt the electrical connection between top and bottom films, the touch panel may develop inoperable regions, or appear to respond in a location that is different than what was activated. Resistive touch panels exhibiting these symptoms have physically worn out.

Micro-Cracking Dependencies

The causes and timeframe of the formation of these cracks depend on many factors, including:

- The force used to compress the films (sometimes called activation force)

- The temperature conditions during compression

The geometry of the object used to compress the films (stylus, finger, or other object), as described below:

A common root cause of accelerated micro-cracking, is the use of a ball point pen to activate a resistive touch panel.

The tip of a common ball point pen consists of a steel ball with an approximate diameter of 0.5 mm. This steel ball is both harder and smaller than the tip of a mobile computer stylus, which is made of plastic and has a diameter around 1.6mm.

When a small diameter instrument, such as a ball point pen, is used, even typical activation forces (250-450 grams) can result in large stresses in the conductive layer. This high stress leads to the accelerated formation of micro-cracks.

Additional damage is done as the hard steel ball also leaves scratches in the comparatively softer top film of the touch panel.

Resistive Touch Panel Benefits

The benefits that contribute to the continued relevance of resistive touch panels include the following:

Their ability to sense user input despite changing environmental conditions. The reliance on physical contact with, and subsequent compression of, the top film creates a sensor which is difficult to inadvertently activate. Rain drops, snow, or other precipitation do not produce enough force to compress the top film of the touch panel; therefore, these environmental conditions do not affect operation.

The dependence on physical contact allows the touch panel to be activated by users wearing any type of gloves that allow for adequate force to be applied to compress the top film.

2. Capacitive Touch Panels

The force-based activation scheme used by resistive touch panels is robust and allows for environmental flexibility, but does not allow for multiple touch inputs. The (projective) capacitive touch panel was developed to enable multi-touch inputs, and as a result, creates a more intuitive user interface.

Gesture-based inputs, such as pinch-to-zoom, reduce the number of steps needed to perform device interactions and simplify the user interface. This simplification for the end user comes at the cost of increased complexity, both at the touch panel hardware and control software levels.

Design and Functionality of Capacitive Touch Panels

A capacitive touch panel is a non-contact sensor that uses changes in capacitance to measure input position. The touch panel consists of two main subcomponents: the sensor and the cover glass.

Structurally, the sensor may be constructed on glass or flexible polymer films; for illustrative purposes this document only describes touch panels that use film sensors.

Like a resistive touch sensor, the capacitive sensor consists of two films. Each film senses input in a single orientation; either along the horizontal or vertical axis. For a single orientation, the conductive surface of the film is etched to create a grid pattern of conductive cells. Each cell projects an electrostatic field above the surface of the sensor.

As a conductive object, such as a human finger, is brought into the projected electrostatic field, some charge is capacitively coupled to the object. A microcontroller then measures the new capacitance as a change in voltage, which is then converted to a position on the touch panel, and ultimately the display.

Microcontroller Integrated Circuit and Firmware

Since this technique measures each conductive cell independently, many times a second, all capacitive touch panels require a specialized microcontroller IC. The firmware run by this IC can control many details of the touch panel function. This includes the distance away from the sensor that a conductive object will be registered as a touch (sensitivity), the size of the object that will register as a touch (resolution), and the frequency that the position will be updated. Uniquely tuned firmware and ICs interact with the mobile device OS in different ways; therefore, changes to these items commonly necessitate OS driver updates.

Capacitive Touch Panel Limitations

The most difficult failure mode to prevent on capacitive touch panels is damage due to point impacts. Point impacts occur in a variety of ways, but most often when a device is dropped to an uneven surface, such as gravel or asphalt.

When a device is dropped face down, small protrusions on the landing surface contact the touch panel. Since such protrusions have a very small contact area, the local stress on the touch panel can reach levels high enough to crack even chemically strengthened glass. These types of failures can be mitigated through device design, but remain a primary contributor to overall capacitive touch panel damage.

Capacitive Touch Panel Benefits

Performance Optimization

The sensor pattern design, controller IC, and controller firmware all contribute to the overall performance characteristics of touch panels. These factors can be tuned to allow the touch panel to perform in various environments, such as in rain or when the input object is not conductive (a gloved hand).

Tuning presents a complex optimization problem whereby performance can be improved, but not always made flawless. Touch panels can be specifically optimized for known customer environments to maximize flexibility.

Within this area of ongoing innovation by touch panel suppliers, new products will leverage the best possible solutions to accommodate their customers.

Mechanical Strength and Resilience

While the sensor itself provides the functional aspect of a capacitive touch panel, the cover glass offers structure and mechanical resilience. The cover glass is often twice as thick as the sensor, although in some industrial applications, it is even greater.

The sensor and cover glass are typically laminated together using optically clear adhesive (OCA), which gives the sensor uniform mechanical strength. The strength of cover glass has improved in the last decade with the introduction of “chemically strengthened” glass. This type of glass increases the touch panel’s ability to bend without breaking and also resists scratching. Bending strength is an important property when developing a product, which needs to survive drops from various heights.

During drops, the structure of a product deforms, causing the touch panel to bend; touch panels constructed from chemically strengthened glass can withstand larger amounts of bending without developing cracks in the cover glass. Additionally, chemical strengthened glass possesses a greater surface hardness compared to non-strengthened glass; this results in a comparatively higher degree of scratch resistance.

Many manufacturers of chemically strengthened glass exist, but Corning Gorilla Glass is currently considered the most resilient.

Manufacturers continue to select the type of touch panel used on new products based on the voice of their customers. The current trends point toward a customer need for intuitive user interfaces and environmental flexibility. These needs have driven the capacitive touch panel (which allows water rejection and gloved operation) to dominate the current product roadmap. Consequently, integration of resistive touch panels has declined, although they continue to serve a niche role for devices that utilize low complexity user interfaces.

We have created a more detailed guide on touch panel types and technology.

Explore Zebra's Range of Mobile Computers

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. Note: Some content or images on zebra.com may have been generated in whole or in part by AI. ©2025 Zebra Technologies Corp. and/or its affiliates.