Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimise workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customise your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Zebra's location technologies provide real-time tracking for your organisation to better manage and optimise your critical assets and create more efficient workflows.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

The everything you need to rapidly and cost effectively develop high-performance AI vision applications on Zebra mobile computers.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labour costs low, your talent happy and your organisation compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximising IT resources and minimising down time.

Make the most of every stage of your scanning journey from deployment to optimisation. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customisation starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximise productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

Which Barcode Label Printing Method Is Right for Me?

The variety of technologies available for barcode printing can be overwhelming. Further complicating the decision is whether it is better to invest in a barcoding system or to purchase pre-printed barcode labels. Deciding between these two options depends on factors such as the volume of labels needed and the budget allocated. Companies with high-volume needs might find it more cost-effective to invest in a barcode system, while those with smaller requirements may find purchasing pre-printed labels more suitable.

On-Demand Vs. Pre-printed Labels

Labels play a crucial role in businesses by streamlining processes and enhancing efficiency, particularly when companies choose preprinted options for their specific operational needs. Thousands of companies have benefited from ordering preprinted barcode labels from service bureaus rather than investing in a barcoding system. Preprinted labels are useful in operations that require only a low volume of identical (i.e., fixed, non-variable data) labels, often with extensive use of colors or graphics.

However, companies that start with preprinted labels quickly discover the limitations of this solution option. Besides restricted flexibility, the use of preprinted labels prevents companies from including variable customer data or combinations of text and barcode information.

As a result, most companies find the financial commitment of printing on-demand barcodes worth the initial investment because of the added value from printing customized information on each label. For many applications requiring high-volume, mission-critical labels, the added cost of preprinted labels quickly exceeds the cost of the entire system. To the surprise of many barcoding novices, most of the companies that order preprinted labels also have barcoding systems. The preprinted labels are ordered with the necessary color, graphics, or standardized text (such as return addresses on shipping labels) and are then fed through a barcode printer to receive customized (i.e., variable) information.

Whether a user elects to use preprinted or plain labels, media selection is critical to the success of any barcode integration. The variety of ribbons, paper, and synthetic labels and tags is too great for discussion in this document, but the barcode application, the intended life span of the label, and the environment to which the label will be exposed all have a direct impact on media selection. It is advisable to pretest a variety of media in an application before purchasing mass quantities. The variety of technologies available for barcode printing can be overwhelming. Further complicating the decision is whether it is better to invest in a barcoding system or to purchase pre-printed barcode labels.

Individuals new to barcoding often gravitate toward familiar technologies (such as laser printers, dot matrix printers, or inkjet printers) that are already connected to a network and, therefore, deemed suitable for barcode labeling. While these printers can be used for some applications, they are often not the ideal solution for professional barcode labeling. The common limitations among these traditional office technologies include print speed and flexibility, as well as the inability to print labels that are durable enough or have the longevity or clarity required for all but the most basic barcoding applications.

What Is Dot Matrix Printing?

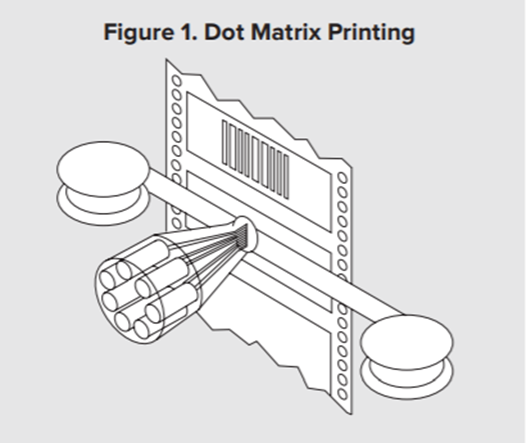

Dot matrix technology uses a hammer or pin to transfer pigment from a ribbon onto the substrate (see Figure 1). Due to the inaccuracy of dot placement and low resolution of the printing technology, these printers are nearly unusable for barcoding.

Advantages of Dot Matrix Printers

Dot matrix printers, while considered a more traditional printing technology, continue to offer several advantages that make them a valuable choice in specific applications. Their unique capabilities and cost-effective features ensure their relevance, particularly in environments where durability and versatility are paramount. Below are some of the key benefits that highlight why dot matrix printers remain a practical option for various printing needs:

- Dot matrix printers are readily accessible and inexpensive to purchase

They can print on virtually any type of form, check, or document and can print on wide-web, multipart (carbon) forms - Dot matrix printers use multi-pass ribbons, which can result in reduced overall cost for ribbons and label materials

Limitations of Dot Matrix Printers

While dot matrix printers offer several advantages, they also come with a set of limitations that can impact their suitability for certain tasks. These constraints stem from their design and technology, which may not align with the demands of more modern printing requirements. Below are some of the key limitations that should be considered when evaluating dot matrix printers for specific applications:

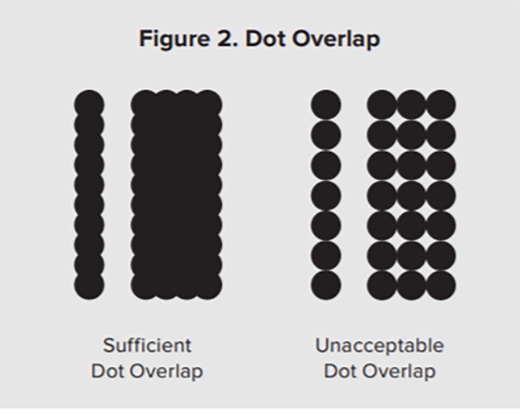

- Dot matrix printers print low- to medium-density barcodes that may not meet certain end-user guidelines. The dot size on the matrix printer limits the narrower element size and density of the barcode

- Continuous ribbon re-use on dot matrix printers requires close monitoring of ribbon condition to ensure adequate barcode contrast. Ribbon ink that has become exhausted can also produce an image that is inadequate for scanning, resulting in a low read rate and a high error rate

- Ink saturation can result in paper “bleed,” which can cause image distortion

- A dot matrix-printed label is limited in durability. Dot matrix printers typically cannot produce chemical- or water-resistant labels

- Printing of single labels results in significant waste. The design of the dot matrix printer’s print carriage, sitting far below the media, also does not allow the label space to be maximized

- Dot matrix printing offers no graphics printing capability

- Barcode print speed is greatly reduced when the best ink coverage for optimal print quality is specified

What Is Inkjet Printing?

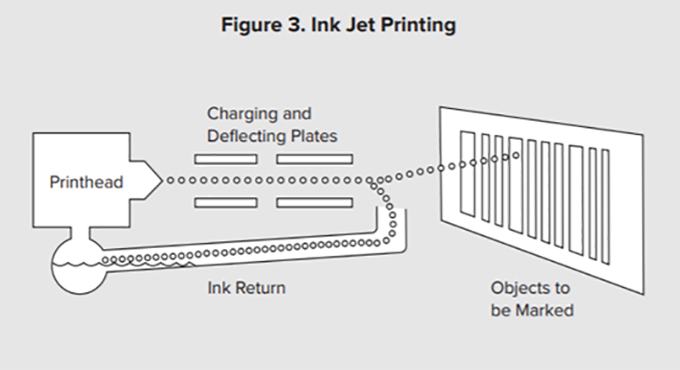

Inkjet printing is used primarily for printing cartons or product packages with barcodes and human-readable data at very high speeds. Inkjet printers spray the ink onto the label surface in either a continuous stream, covering the entire print width with one spray, or one drop at a time (see Figure 3). However, inkjet printing is not acceptable for most barcoding applications.

Advantages of Inkjet Printers

- The initial cost of inkjet printers is generally lower than that of laser printers.

- Direct inkjet printing requires only one step, while label printing requires two: printing the label and adhering the label to the product

- High-speed inkjet printing is a favorite on high-speed production lines due to its ability to mark 'on-the-fly'

Limitations of Inkjet Printers

- Inkjet printers are often too slow and are unable to reproduce barcodes with acceptable accuracy

- System installation is costly because it is designed for high-volume barcode printing—not for individual or small batch printing

- Inkjet printing requires diligent supervision and maintenance to ensure consistent print quality and prevent inkjet clogging

- Dot placement accuracy and barcode density/resolution are limited due to ink splatter and because the print surfaces are in continual motion

- Most inks used with this technology are water-based and, therefore, streak, run, or blur when they come in contact with water. Non-water-soluble inks are available, but these inks often produce a shine that reflects light back to the scanner, rendering the barcode unscannable

- Barcodes printed on the dark background of corrugated box materials suffer from poor contrast and poor readability

- Scanning devices must be carefully chosen to ensure reliable barcode reading

What Is Laser Printing?

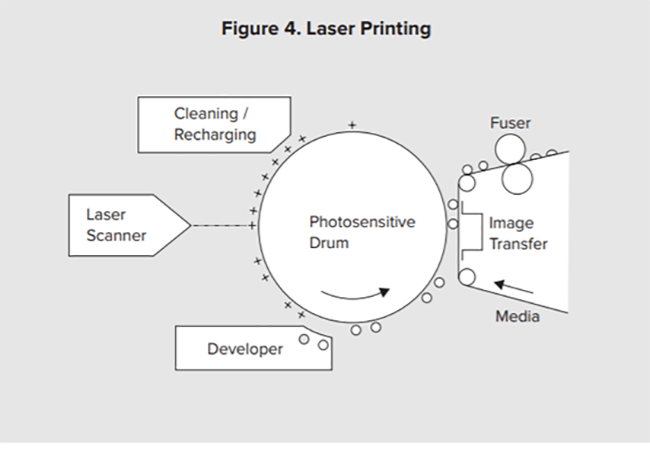

Laser printing involves using a laser to create a charged pattern on a print drum, which then attracts toner particles to form an image on paper. The laser printer works much like a photocopier; it projects controlled streams of ions onto the surface of a print drum, resulting in a charged image. The charged image then selectively attracts toner particles, transferring the image onto the paper substrate. After the image is transferred to the media, the heat and pressure of the fuser cause the image to adhere to the media.

Advantages of Laser Printers

- Laser printers are good at producing plain paper documents that require barcodes

- They can print high-quality text and graphics on paper documents and can double as a document printer when not being used to print barcodes

- Barcode density and resolution are also quite high on laser printers, resulting in a scannable code at virtually any wavelength using an infrared scanner

Limitations of Laser Printers

- Laser printers are not well suited for industrial or individual-product labeling operations. They can be wasteful, as they cannot produce single or small labels. A minimum of half a page of media is typically required for the printer to maintain control of the sheet. Unless the label is at least that size or multiple labels are needed at once, the remainder is wasted.

- Laser printer label adhesives must be carefully selected to ensure stability under the heat and pressure of the fuser. Otherwise, the adhesive may extrude onto the printer mechanism where it captures stray toner, or may cause the labels to curl at the edges. Because of the pressures used in the laser printer image transfer process, many laminated label materials are not compatible with this technique. Those materials that are compatible may not always be available in the sheet form necessary for laser printing.

- Laser printing is susceptible to toner flaking and smudging, making the technology unsuitable for long-term barcoding.

- A laser-printed paper label has limited durability. For example, laser printers cannot produce chemical- or water-resistant labels and images.

- Toner, drum, and supply costs can skyrocket when printing barcodes instead of typical text on laser printers. While text generally requires only about 5 percent black ink coverage, barcode needs can exceed 30 percent. Toner costs alone could be six times higher when printing barcodes rather than text.

Thermal Printing Technology

The most widely used technologies for dedicated barcoding systems are direct thermal and thermal transfer printing. While both technologies use a heated printhead to create the image on the label, they are suited to different applications.

There are two type of thermal printing technologies to print a barcode, direct thermal and thermal transfer. While there are distinct differences, in both cases heat is used for the print process. Direct thermal printing uses heat sensitive media, which is chemically treated, that blackens when passed under a thermal printhead. Conversely thermal transfer printing creates long-lasting images on various materials by using a heated ribbon in the process.

You can learn more about Direct Thermal and Thermal Transfer Printing by reading our dedicated FAQ which looks into the main differences between Direct Thermal and Thermal Transfer Printing.

Integrated Barcode Systems

Though the advance of barcoding has created new data management opportunities, much of the potential of barcodes remains untapped. Most barcode printers are connected to stand-alone personal computers (PCs) that control the barcode label design and function via a network print server. While these stand-alone systems, dubbed “island systems,” can still take advantage of barcode scanning to provide data automation, human users must direct the printer to print and manually enter nearly every piece of information.

More recently, enterprise resource planning (ERP) software has given barcoding an enhanced role in corporate information systems. In island systems, the barcode printer has no direct interaction with the corporate enterprise. When connected to an ERP system, the printer can take direction from other processes and print and encode data automatically when the server directs it to do so.

ERP systems, when used alone or partnered with warehouse management software or supply chain management applications, are capable of producing detailed reports based on the information they gather from the system operations. This reporting capability can be used with barcode integration software to print labels containing this same information.

Barcode Print Technology Matrix

| Technology | Print Quality | Scanner Readability | Initial Installation Cost | Long-Term Maintenance Cost | Materials Waste |

| Dot Matrix | Fair | Low | Low / Moderate | Moderate / High | High |

| Ink Jet | Moderate | Low / Moderate | High | Moderate / High | High |

| Laser | Moderate | Moderate | High | Moderate / High | High |

| Direct Thermal | Moderate / Excellent | Moderate / Excellent | Moderate / High | Low | Low |

| Thermal Transfer | Excellent | Excellent | Moderate / High | Low | Low |

Learn More About Zebra's Range of Printers

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. Note: Some content or images on zebra.com may have been generated in whole or in part by AI. ©2025 Zebra Technologies Corp. and/or its affiliates.