Is Your Utility or Energy Company Deploying Technology for the Right Reasons?

The five-year roadmap for field service-focused technology modernization is innovative – dramatically so.

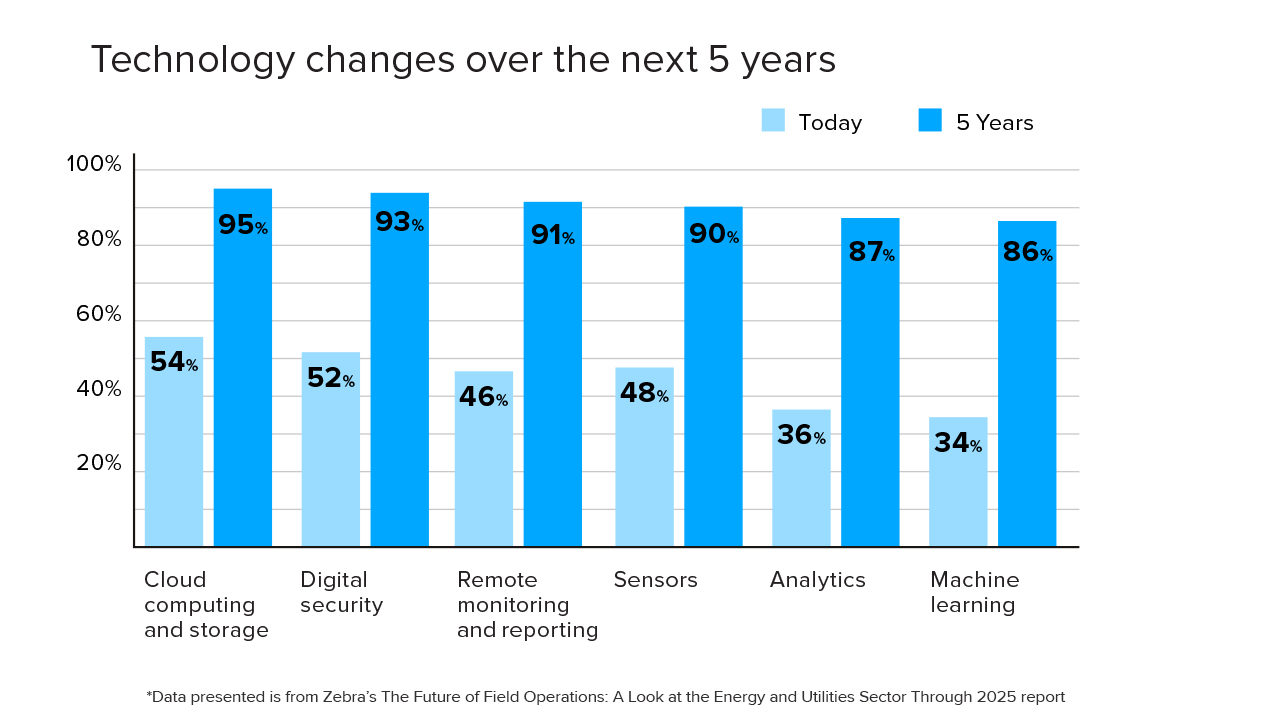

Companies that participated in a new study from Zebra – “The Future of Field Operations: A Look at the Energy and Utilities Sector Through 2025” – shared an outlook that includes everything from improvements in cloud computing and security to the introduction of newer augmented reality and autonomous vehicle use cases.

While you may not be surprised at the planned technology utilization, you have to admit that the simultaneous onboarding of so many different technology platforms is ambitious, even if necessary. It takes a lot to develop these capabilities, and perhaps even more work to evaluate and deploy technologies like these. To do it well, one has to fully understand what a new technology can and cannot do.

The Sky is the Limit with Advanced Technology. (Or Is It?)

Understanding the boundary conditions is part of the knowledge-building work needed. For example, while autonomous vehicle tech can successfully manage a lot of “normal” driving conditions, snow-covered roads are a boundary condition – an area where the technology may be inferior (or even dangerous) when the conditions cross that boundary.

As a longtime mobility solution architect for those with field-based workforces, I have often been asked for advice on which device, which software and which partner is best for organizations, given their goals. This often prompts further discussion about what those goals are exactly and has a tendency to lead to the personally worrisome “Couldn’t we just ...?” set of questions:

- “Couldn’t we just use email for dispatch?”

- “Couldn’t we just collect notes on work tickets at the end of the day?”

- “Couldn’t we just use a cheap throwaway consumer tablet?”

These three common questions are among those that always raise a red flag for me. It’s not because they are bad questions to at least ask. It’s because of the potential consequences that customers could face if someone in my position – a sales engineer or solution architect – were to say “yes.” Telling a customer that it can do one of these things, in my opinion, is masking the fact that it has a real problem to solve – or a real opportunity to do things better. And the alternative of green lighting a mobile device or software selection just to check off a box on a technology to-do list – in order to claim that you’re a “mobile-enabled” organization – is one of the easiest ways to introduce risk into your organization.

In fact, implementing new technology just for the sake of keeping up with competitors – or trying to get an edge on them – may land you further behind than you were before you made such an investment. If the mobility solution you implement doesn’t give you a better and more reliable way to capture, analyze and act on data across your business, then the return on investment will be disappointing and the technology will be deemed a failure (whether by your workers or bosses). I spoke of such execution challenges and the common consequences in a previous blog, but know that such issues (and considerations) are not unique to mobile technology.

For example, there is indeed a right and wrong way to implement something as seemingly straightforward as a barcode scanning application, and the hardware and software solutions you will require to ensure workers successfully scan barcoded assets every time will vary based on the workflow, work environment and end-user work style. Yes, you can tell workers to use a camera app on their smartphones or tablets to “check the box” of enabling barcode scanning for certain workflows. However, if they need to scan barcodes attached to a piece of equipment far above their heads or down in a utility hole below, you really need to give them an enterprise-grade mobile device that has a dedicated extended range scan engine built in. The range of these scanners is usually measured in feet instead of inches and can save the time and risk of workers climbing up or down ladders.

You also have to remember that you need specialized scanners to read dirty, wet, damaged or faded barcodes –even from a few inches away. Considering that several utility and energy companies’ assets are exposed to the elements 24/7/365, it is highly unlikely that your workers will have the luxury of scanning “clean” barcodes out in the field.

A Hard Lesson Learned by a Market-Leading Water Utility

Recently, I attended a UAS (Unmanned Aerial Systems) Conference where a number of engineers and visionaries developing and deploying professional-level drones were sharing experiences, issues and plans with one another and end users, including several utility and energy companies.

Utilities have been one of the first beneficiaries of industrial-grade drones due to their need for regular inspections and the convenience of having an eye in the sky. As one utility expert added up, there are one million miles of pipelines in the U.S. alone that must be inspected twice a year. Using drones to complete this cumbersome task results in a huge cost reduction when you consider how many field workers in trucks or visual inspectors with binoculars in small planes it would otherwise take to accomplish this task. The business case for a new drone-driven workflow would seem pretty cut and dry. Yet it’s not, as the technology head of one of the nation’s largest water utilities explained.

His utility, sold on the benefits of drones, first started using them to examine water towers and other parts of its treatment facilities. His department had developed best practices for the whole utility to follow, but each facility has some autonomy on how it manages inspections – and that quickly became a problem.

He has had to endure each facility’s attempt at deploying consumer drones (because they’re cheap) and then standby as they failed. (He recounted how a few treatment plants even went to Best Buy for their first drones.)

Then, in an attempt to correct course, the facilities would subsequently hire unqualified contractors who tried to deploy modest drones without proper standard operating procedures (SOP). This just made matters worse and, not surprisingly, those drones also failed in their mission. Clearly, these facilities were doing the “Couldn’t we just…?” drill, which took some time to halt.

The utility ultimately had to train its plant managers on how to select and monitor their contractors. Although, even that step wasn’t enough. The utility is now developing its own drone SOP to ensure the facilities are only investing in drones that have been purpose-built specifically for the types of inspection applications it’s running in its unique operating environments.

For example, the utility requires cameras with GPS that can overlay what it is inspecting with the geospatial information system (GIS) applications that its field service technicians use. When issues are found during inspections, the field techs who are dispatched to resolve them must have access to information on the issue and the asset location as well as associated work orders – all of which are tied into GIS. When the utility’s distributed facilities were using inadequate GPS-tagging cameras, the technicians would have to thoroughly read inspection reports and manually figure out where an issue might be located, then go to their GIS-enabled application on their mobile devices or computers and manually enter the info. Now, with the right devices and the right SOP, the drones can fly exactly where they need to inspect, then tag each photo for a GIS overlay, in the same format that the utility’s ground-based technicians use to locate and maintain the assets. (There are competing GIS suppliers and some drone cameras were using a different format.) With the right info in the right format, the inspection team just has to find suspicious spots – sometimes with an artificial intelligence (AI) assist – and tag that spot for dispatch.

Wow, could I relate to what this utility executive experienced!

What You Can Learn from This Utility When Deploying New Technology for Your Field Operations

This story of trying cheap tools first, then learning from experts, then using the right tools for the right job is an experience I’ve had in the mobile handheld and tablet computing world with multiple organizations running field service applications in my 25+ year career.

So many field organizations, when moving from paper to digital or moving from email on a phone to an integrated software and hardware solution, have gone down a path just like the one described by the water utility deploying drones.

Many first go the path of cheap consumer tablets – not in spite of but because they are cheap. Things might start to work better than legacy processes, then failures happen. Failure in devices, failure in effectively dispatching, failure to remove the back-office paper-to-invoice data entry and, ultimately, failure to satisfy their customers.

From there, many try to upgrade to a better system. But having had a bad experience, they are wary to fully embrace a new system. Sometimes a series of half steps is taken, with predictably poor results.

At the end of the day, the successful companies get there – they find a partner with experience in their field, they match the right software to the right hardware and eventually find themselves able to support their field operations with a reliable, performance-driven mobility solution running within a secure, cloud-based environment.

A Word of Caution When Defining Your Roadmap

There is an unfortunate reality to the impact of poorly-chosen field mobility solutions on the IT and operations departments. I’ve never seen management accept that IT is struggling to support the field because the solution that management chose for field-based workers and workflows was inadequate. Management will want IT to work harder and hit goals for field uptime and cost containment, which the field implementation just isn’t capable of achieving. IT staff is then judged to be underperforming.

My advice?

Always have the end goal in mind and remember to learn from the mistakes of others, instead of making the same mistakes yourself. (General Patton famously said that his goal was to make the enemy soldiers die for their country, rather than have his soldiers die for his.)

First, talk with a solution provider with a lot of experience in field service deployments. Tell them what you want and listen to their recommendations. Ask questions and push back to make sure that the solution fits you. It also helps to talk to other organizations that share similar goals to understand what worked for them, what didn’t and why.

As you can see in Zebra’s latest “The Future of Field Operations” report, there are several operational areas where improvements have been reported – or anticipated – as a direct result of mobile technology utilization.

You can expect similar results if you invest in the right technology solutions for your goals.

As demonstrated by the water utility’s story I just shared, if the value your workers deliver to your business and customers is dependent on them always being in the right place at the right time with the right information to take immediate and effective action, then it is mission critical that the mobile devices you give them can successfully dispatch that info, reliably sync with the right systems and run GIS overlay applications without issue. Utilities cannot afford to normalize the risk of potential device failure.

That is why rugged tablets and handhelds have long been preferred by utility and energy companies and remain the right choice despite the availability of “rugged” consumer devices. Any downtime, whether due to mobile device damage from a drop, water or dust, will cost your organization far more than the money saved buying an inadequate device. It’s also the reason why I strongly advocate for utilities, mining and oil and gas companies to consider the “total benefits of ownership” and not just the bottom line “total cost of ownership.”

There is a ton of engineering that goes into many of the things we interact with in our world, from electronic technology to valves and even toilets. Those things that seem simple are often designed and built so well that most of us can’t even imagine the many items that were designed just right so that they would blend into the solution, such as the faucet handle or curb valves. The reward is a system that just works, that goes unnoticed.

In your case, if the technology solution that’s supposed to empower your critical field operations causes problems, it’ll get noticed in a hurry.

Want to Avert Technology Failures and Achieve Your Desired Outcome from Day One?

Pick a strategic technology partner who has proven its ability to build and support a robust, effective and integrated solution, with software apps that are stable and hardware that’ll stay connected, stay useful through any weather condition and reliably operate despite whatever harsh environment must be endured. In turn, you’ll be rewarded with a productive, happy and safe workforce, happy customers – and even happier bosses.

Bob Ashenbrenner

Durable Mobility Technologies, LLC, under the direction of Bob Ashenbrenner, works with Zebra Technologies to develop future-proof mobility solutions for customers across multiple field service and industrial sectors. As an industry consultant, Durable Mobility Technologies, LLC, is focused on optimizing rugged tablet-based solutions for mobile workers of all kinds, including utility and public safety professionals. Ashenbrenner is particularly committed to helping customers identify mobile devices that survive a tough work day, run all the software and tools needed today, and will remain flexible and scalable to adapt to evolving technology applications as business needs dictate.

Ashenbrenner has more than 25 years of computer engineering and engineering management experience, with 18 of those specific to mobility and the field requirements that enable real work to happen. He was previously a Solutions Architect with Xplore Technologies and Motion Computing for 13 years. In that role, Ashenbrenner led the development of a suite of rugged mobile tablet computer, services and software, with an emphasis on supporting the whole mobile work environment.