DS3600-DPA Ultra-Rugged Scanner

Unstoppable performance for Direct Part Marks (DPM), 1D/2D and wide 1D barcodes in industrial manufacturing

Zebra’s DS3600-DPA Ultra-Rugged scanners are designed to help industrial manufacturers enhance track-and-trace applications to control product quality, protect consumer safety and ensure regulatory compliance—whether in automotive, aerospace, farm and fleet or other industries. With one device, workers can capture virtually any direct part mark, as well as 1D/2D and wide 1D barcodes. Built for your toughest environments, the DS3600-DPA is nearly indestructible, including an enhanced 10 ft./3 m drop spec to concrete and dual IP65/IP68 sealing. Zebra’s EA3600 Network Connect for Automation connects to your Industrial Ethernet network without third-party conversion equipment. Plus, with DataCapture DNA, you can simplify every stage of the scanning experience over the life of your device to help ensure traceability, reduce production cycle times and prevent unplanned production-line downtime.

Performs in Your Toughest Environments

Capture Direct Part Marks, 1D/2D and Wide 1D Paper Barcodes

Zebra’s exclusive PRZM Intelligent Imaging technology enables the capture of virtually any direct part mark including laser etch, ink mark, chemical etch, inkjet mold, cast, thermal spray and dot peen. The same scanner can capture virtually any barcode printed on a label—including damaged, dirty, poorly printed or under shrinkwrap—as well as 4-inch wide 1D barcodes found on picklists, carton labels

and packages. This dual functionality allows you to use the same scanner on the production line for end-to-end track and trace as well as throughout the plant floor and warehouse.

Ultra-Rugged—the Most Indestructible Design in its Class

Ready for the world’s harshest environments, the DS3600-DPA has the highest drop, tumble and sealing specifications in its class. It can survive 10 ft./3 m drops to concrete and 7,500 tumbles. With dual IP65/IP68 sealing, the DS3600-DPA is dust proof, can handle the force of jetting water and be fully submerged in water. Built to withstand extreme heat, cold and humidity, the DS3600-DPA can be used anywhere—indoor, outdoor and even in the freezer.¹

Ultra-Rugged Cradle and Charging Contacts Designed to Last

The DS3600-DPA is the first scanner in its class to offer a cradle with IP65 sealing. Its industrial charging contacts withstand 250,000 insertions. And Zebra’s exclusive Connect+ Contact technology assures reliable, corrosion-free charging over the life of the scanner.

Advanced Illumination System

Advanced illumination provides the multiple lighting effects required to capture marks on any type of surface—including reflective, irregular and curves as well as low and high contrast marks. The built-in diffuser provides the indirect light required to capture marks printed on very shiny and reflective surfaces. The proprietary design of the diffuser also directs additional lighting to the edges of barcodes marked on a curved surface, enhancing the image for easier decoding. Finally, a glancing direct light mode provides the bright light required to successfully read low-contrast barcodes marked on any type of surface, including challenging polished materials.

The DS3600-DPA—Streamline end-to-end product traceability in industrial manufacturing with the ultra-rugged scanner that redefines reliability and versatility.

For more information, visit www.zebra.com/ds36x8-dpa

Connect to Your Industrial Ethernet Network Without Third-Party Converter Boxes

Zebra’s Network Connect for Automation delivers a seamless connection between DS3600-DPA scanners and a manufacturer’s Industrial Ethernet network without the need for third-party conversion equipment. The solution supports a wide range of programmable logic controller (PLC) vendors, including support for EtherNet/IP for Rockwell Automation, PROFINET for Siemens, as well Modbus TCP and standard TCP/IP. By streamlining the connection between scanners and the PLC, Network Connect eliminates vulnerability points, improves security and reduces complexity.

Easily Capture Label Data for Better Inventory Management

With Label Parse+, the DS3600-DPA can instantly capture and parse GS1 label barcode data on items, enabling workers to easily capture a wealth of data, including expiration dates and lot number/manufacturing location.

Read Up To 20 Barcodes With One Press of the Scan Trigger

With Multi-Code Data Formatting (MDF), the DS3600-DPA can capture multiple barcodes with a single scan and transmit only the barcodes you need, in the order your application expects.

Faster Pick-List Processing

Users can easily select and capture an individual barcode from any pick list.

Flexible Feedback Modes

Mix and match the feedback modes that best fit your environment— vibration, wraparound LEDs that are easy to see from any position, a beep tone and Zebra’s Direct Decode Indicator that projects illumination on the captured barcode.

Superior Cordless Technology

More Than 100,000 Scans on a Single Charge

The PowerPrecision+ battery delivers the ultimate in battery power and management. You get more than three times the amount of scans per charge than with competitive models in this product class, so workers can scan more items over a longer period of time. You also get visibility into a wealth of battery health-related data, including charge cycles consumed, current battery status and a State of Health meter, which identifies if batteries are healthy and holding a full charge or ready for retirement.

Battery and Bluetooth™ Status At-A-Glance

The first-in-its-class battery ‘charge gauge’ and Bluetooth status LED make it easy to monitor battery power as well as Bluetooth connectivity.

Switch Workflows in an Instant with AutoConfig

Since scanner settings are stored in the cradle base, simply pair the DS3600-DPA to a different base to automatically configure it for a new host application. For example, you can take a scanner from the manufacturing line and use it for shipping without manually changing settings.

Keep Track of Your Scanners and Prevent Workflow Interruptions

With Virtual Tether, you won’t have to worry about a warehouse worker leaving a scanner behind on a pallet. Both the scanner and cradle will alert users when a scanner is taken beyond its Bluetooth range or left out of the cradle for a predefined length of time.

Eliminate Bluetooth Interference with Wi-Fi Friendly Mode

Zebra’s exclusive Wi-Fi Friendly Mode eliminates the wireless interference that Bluetooth devices can create in your Wi-Fi environment.

Unrivaled Manageability

Identify and Correct Problem Barcodes with ScanSpeed Analytics

Only from Zebra, ScanSpeed Analytics provides detailed metrics on every barcode captured—enabling you to identify poor performing barcodes that slow down your operations.

No-Cost Tools to Meet Your Management Needs

With 123Scan, you can easily create configuration barcodes to program scanners. If your imagers are in multiple locations across the country or around the world, with Scanner Management Service (SMS), you can configure and update the firmware for any DS3600-DPA device that is plugged into the host—no depot staging or user action is required.

Up-To-The-Minute Insight Into Every Aspect of Your Scanners

The logging agent’s Remote Diagnostics capabilities automate the recording of scanner asset information, health and statistics, configuration settings and barcode data—giving you the information needed for event verification, blockchain traceability, pilot site ROI generation, troubleshooting and predictive fleet-wide trend analysis.

Specifications

Physical Characteristics

| Dimensions | Corded: 7.3 in. H x 3.0 in. W x 5.2 in. D |

| Weight | Corded: 10.72 oz./304 g Cordless: 14.18 oz./402 g |

| Input Voltage Range | Host powered: 4.5 VDC min., 5.5 VDC max. External power supply: 11.4 VDC min., 12.6 VDC max. |

| Operating Current | DS3608-DPA (corded): 360 mA (RMS typical) |

| Standby Current | DS3608-DPA (corded): 100 mA (RMS typical) |

| Color | Gray and Black |

| Supported Host Interfaces | USB, RS232, Keyboard Wedge Industrial Ethernet: EtherNet/IP, Profinet, Modbus TCP & Std TCP/IP |

| Battery | PowerPrecision+ 3100 mAh Li-Ion rechargeable battery |

| User Indicators | Direct decode indicator; LEDs; beeper; vibration |

Performance Characteristics

| Scans per Full Charge | 100,000+ |

| Image Capture | Basic |

| Illumination | Direct: Two (2) warm white light LED; Diffuse: Ring of red 634 nm LEDs |

| Aimer | 655 nm laser |

| Imager Field of View | Horizontal: 46°, Vertical: 30° |

| Image Sensor | 1,280 x 960 pixels |

| Minimum Print Contrast | 15% minimum reflective difference |

| Skew/Pitch/Roll | Skew: ± 60° Pitch: ± 60° Roll: ± 360° |

Decode Capabilities2

| 1D | Code 39, Code 128, Code 93, Codabar/NW7, Code 11, MSI Plessey, UPC/EAN, I 2 of 5, Korean 3 of 5, GS1 DataBar, Base 32 (Italian Pharma) |

| 2D | PDF417, Micro PDF417, Composite Codes, TLC-39, Aztec, DataMatrix, MaxiCode, QR Code, Micro QR, Chinese Sensible (Han Xin), Postal Codes |

| IUID Support | Supports IUID parsing, the ability to read and separate IUID fields per application requirements |

User Environment

| Operating Temp. | Corded: -22° F to 122° F/-30° C to 50° C Cordless: -4° F to 122° F/-20° C to 50° C |

| Storage Temp. | -40° F to 158° F/-40° C to 70° C |

| Humidity | 5% to 95% non-condensing |

| Drop Specification | DS36X8: Withstands multiple 10.0 ft/3.0 m drops to concrete at room temperature DS3678: Withstands multiple 8.0 ft/2.4 m drops to concrete at -20° C to 50° C DS3608: Withstands multiple 8.0 ft/2.4 m drops to concrete at -30° C to 50° C |

| Tumble Specification | 7500 3.3 ft./1.0 m tumbles |

| Sealing | Scanner: IP65 and IP68 per applicable IEC sealing specifications FLB cradle: IP65 |

| ESD | Per EN61000-4-2, ±20 KV air discharge, ±10 KV direct discharge, ±10 KV indirect discharge |

| Ambient Light Immunity | 0 to 10,037 Foot Candles/0 to 108,000 Lux (direct sunlight) |

Utilities and Maintenance

| 123Scan | Programs scanner parameters, upgrades firmware, provides scanned barcode data and prints reports. For more information, visit www.zebra.com/123Scan |

| Scanner SDK | Generates a fully-featured scanner application, including documentation, drivers, test utilities and sample source code. For more information, visit www.zebra.com/windowsSDK |

| Scanner Management Service (SMS) | Remotely manages your Zebra scanner and queries its asset information. For more information, visit www.zebra.com/sms |

| Network Connect | Seamlessly connects 3600 Series scanners directly to your Industrial Ethernet network with no additional conversion equipment. For more information, visit www.zebra.com/NetworkConnect |

Wireless Connectivity

| Bluetooth Radio | Bluetooth Class 1, Version 4.0 (LE), serial port (SPP)and HID profiles |

| Data Rate | 3 Mbit/s (2.1 Mbit/s) for Classic Bluetooth |

| Radio Range | Direct line of sight in open air: Class 1: Minimum 300 ft. (100.0 m); Class 2: Minimum 30 ft. (10.0 m) |

Regulatory

Environmental | RoHS EN 50581: 2012 |

| Electrical Safety | EU Safety: EN 60950-1: 2006 + A11: 2009 + A1: 2010 + A12: 2011 + AC 2011 + A2: 2013; International Safety: IEC 60950-1: 2005 + A1: 2009 + A2: 2013 US/Canada Safety: UL 60950-1, second edition, CAN/CSA-C22.2 No. 60950-1-07 |

| Laser/LED Safety | Exempt Risk Group LED per IEC/EN 62471 (Ed 1) Class 2 Laser per IEC/EN 60825-1 (Ed 3) Complies with 21CFR1040.10 |

| EMI/RFI | IT Emissions: EN 55022: 2010/AC: 2011 (Class B); IT Immunity: EN 55024: 2010; Heavy Industrial: EN 61000-6-2: 2005/AC:2005; Harmonic Current Emissions: EN 61000-3-2: 2006 + A1: 2009 + A2: 2009 (Class B); Voltage Fluctuation and Flicker: EN 61000-3-3: 2013; Medical Electrical Equipment: EN 60601-1-2: 2007/AC: 2010, IEC 60601-1-2: 2007 (Modified); Radio Frequency Devices: 47 CFR Part 15, Subpart B, Class B Digital Apparatus: ICES-003 Issue 5, Class B |

Decode Ranges (Typical)3

Symbology/Resolution | Near/Far |

| Code 39: 3.0 mil | 0.5-4.7 in./1.3-11.9 cm |

| Code 39: 5.0 mil | 0.2-5.6 in./0.5-14.2 cm |

| PDF417: 6.6 mil | 0.1-4.0 in./0.3-10.2 cm |

| Datamatrix: 5.0 mil | 1.2-2.9 in./3.0-7.4 cm |

| Datamatrix: 10.0 mil | 0.1-4.9 in./0.3-12.5 cm |

| QR: 10.0 mil | 0.1-4.8 in./0.3-12.2 cm |

| 100% UPC: 13.0 mil | ⁴1.0-5.8 in./⁴2.5-14.7 cm |

| C128: 15.0 mil | ⁴3.3-10.0 in./⁴8.4-25.4 cm |

EA3600 Network Connect Industrial Ethernet

| Network Protocols Supported | Ethernet/IP, Profinet, Modbus TCP, TCP/IP |

| Certification | ODVA EtherNet/IP, PROFIBUS |

| Standards | Complies with IEEE 802.3af standard |

| Power | 12 VDC or 24 VDC, 1 amp |

| LED Indicators | LED1 for Power: bi-color green/yellow LED; Green: unit powered and OK; yellow: in bootloader LED2 for Link Status: blinking yellow LED controlled by the PHY indicating Ethernet traffic |

| Mounting | DIN rail brackets; mountable to both wide (120mm) and slim (35mm) DIN rails |

| Industrial Ethernet Customer Application Development | Device Definition Files (Profinet and EtherNet/IP): EDS file; GSD file; a single sample application that can switch between the three scan modes for TIA (Totally Integrated Automation) v13 or higher, Step 7 v 5.5, Logix Studio 5000 v24 Function Block (FB) for Siemens IDE’s: TIA, Step 7 v5.5 (Step 7 v5.5 FB should take in IO Addresses in INT form) Routine for Rockwell IDE |

Warranty

Subject to the terms of Zebra’s hardware warranty statement, the DS3608-DPA/DS3678-DPA is warranted against defects in workmanship and materials for aperiod of: Scanner and Cradle: thirty-six (36) months, Battery: twelve (12) months from the date of shipment. For complete warranty statement, go to: |

Recommended Services

| Zebra OneCare™ Select; Zebra OneCare Essential |

Footnotes

| 1. Heated scanner holder accessory recommended to reduce condensation on the outside of scan window when moving in and out of freezers. 2. Refer to Product Reference Guide for complete list of symbologies. Specifications are subject to change without notice. 3. Printing resolution, contrast, and ambient light dependent. 4. FOV/barcode width limited; Decode ranges measured with DPM Mode OFF, photographic paper barcodes, under 30fcd ambient light conditions. |

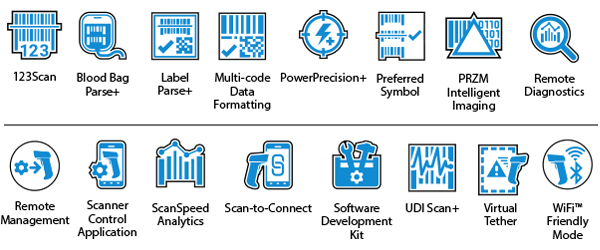

DataCapture DNA

| For more information about DataCapture DNA and its applications, please visit www.zebra.com/datacapturedna |

The Zebra 3600 Ultra-Rugged Scanner Series

This family of scanners offers a model to meet virtually every need in warehousing and manufacturing

- LI3600-SR: Standard range 1D barcode capture

- LI3600-ER: Extended range 1D barcode capture

- DS3600-SR: Standard range scanning of 1D and 2D barcodes

- DS3600-HP: High-performance scanner captures 1D/2D barcodes over longer distances, plus OCR, photos and documents

- DS3600-HD: Captures high-density 1D/2D barcodes

- DS3600-DP: Capture of DPM

- DS3600-ER: Extended range 1D/2D barcode capture

- DS3600-DPA: Optimized to read DPM and wide 1D barcodes

- DS3600-KD: Versatility of a keypad and color display

The Zebra wordmark and logo are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2026 Zebra Technologies Corp. and/or its affiliates.

05/13/2021 HTML