Cepheid Speeds Up PCR Test Kit Delivery and Boosts Productivity with RFID ‘Grab & Go’ Solution

Cepheid is a global leader in molecular diagnostics that develops and distributes Polymerase Chain Reaction (PCR) test kits for clinicians and patients throughout the world.

Zebra Success Story: Cepheid

Overview: Healthcare Challenge

Cepheid needed to bring PCR test kits to market faster and increase the velocity of its supply chain. Meanwhile, scientists, chemists and manufacturing associates were spending time on non-value-add tasks to move raw materials limiting the time they could dedicate to developing new infectious disease tests and supporting PCR kit production.

Benefits / Outcomes

- 28,000+ yearly touchpoints eliminated through automation

- 7,000+ manual transactions eliminated

- 2,300 hours, 96 full days of work saved in 9 months

- $250,000 savings through increased efficiency

About Cepheid

In healthcare, time isn’t just money—it’s survival. The sooner a disease is caught, the better the odds of providing the patient with the proper treatment. Whether it’s a fast-moving infection or cancer, early detection saves lives.

That urgency drives Cepheid, a major player in molecular diagnostics. Following its mission: to find “A Better Way”, Cepheid strives to make disease detection faster, easier and more accurate. Its real-time Polymerase Chain Reaction (PCR) tests help detect healthcare threats early, anytime, anywhere, within the same day.

The COVID-19 pandemic put Cepheid’s research in the spotlight. With a global network of GeneXpert diagnostic systems, the company delivered over 100 million COVID-19 tests, helping slow the spread when it mattered most. Following this success, Cepheid saw an opportunity to move even faster—by addressing a critical pain point: the supply chain and manufacturing of its PCR kits. “We knew we had the most modern facilities, the best scientists and a bold vision,” says Ingo Beck, Senior Director of Operations at Cepheid. “But our supply chain was too slow, and manual inventory tracking was holding us back. If we want to meet increased demands, we’ll need a better solution to get our PCR test kits to individuals faster.”

The Challenge

Cepheid leaders envisioned a fully automated, 24/7 warehouse where materials moved on their own—with no human hands needed. Its top scientists were bogged down with paperwork to get the necessary chemicals—highly skilled and well-paid individuals whose time could be better spent on more valuable tasks. Additionally, the manual process of procuring the required chemicals led to inventory mistakes, delays, extra costs and wasted materials.

Moreover, the inventory management process was outdated, slowing down workflows. Each transfer required up to five unnecessary steps and took between five to 30 minutes. A warehouse associate then had to manually enter the data from the forms into an SAP ERP application, which caused discrepancies in information across different systems. On top of that, the transfer forms were often unreadable, creating even more inventory variances, shortages and additional delays in manufacturing.

Cepheid needed a faster, more accurate way to track inventory without wasting valuable Manufacturing and R&D time. But this wasn’t just any tech upgrade. “We work in a high-stakes, highly regulated industry,” says Michael DeClue, Director of Chemistry R&D at Cepheid. “Biological samples require precise temperature control, otherwise, mislabeled samples can compromise patient and in-lab safety.”

To address these needs, Cepheid turned to Zebra and InThing, a Zebra Premier Advanced Location Technology ISV partner, to oversee the implementation. Cepheid’s goal was to streamline workflows across 18 unique R&D and chemistry manufacturing labs by setting up a raw materials RFID system to complete SAP ERP transactions, record expense material in the financial general ledger and track inventory across the various lab locations.

In less than a year, our productivity savings skyrocketed—by over 1,000%!

The Solution

The implementation team mapped out every step, from incoming goods to R&D and Manufacturing, identifying unnecessary touchpoints and paperwork that slowed down the flow of raw materials before they reached production. “We envisioned a ‘Grab & Go’ system, where scientists, chemists and manufacturing associates could enter the inventory warehouse 24/7 to take the raw material commodities they needed, such as liquids, powders and hazardous chemicals, and head right to their lab location without wasting a second on bureaucracy and paperwork,” explains Tom Healy, Director of Logistics Technology and Project at Cepheid.

Each of the 18 locations within the manufacturing process needed a custom setup—tag placement, hardware repositioning and signal fine-tuning—to hit 100% readability. Additionally, the laboratory setting meant the team had to work on tagging an unpredictable inventory mix, including liquids, metals and solids, some frozen at -80°C, some toxic, corrosive and even flammable. “We had everything from 2-liter chemical bottles to 300-pound metal drums,” says Healy. “Plus, we had solid metal doors and fireproof cabinets that bounced RF signals, preventing us from getting accurate reads when entering the RFID gateways.”

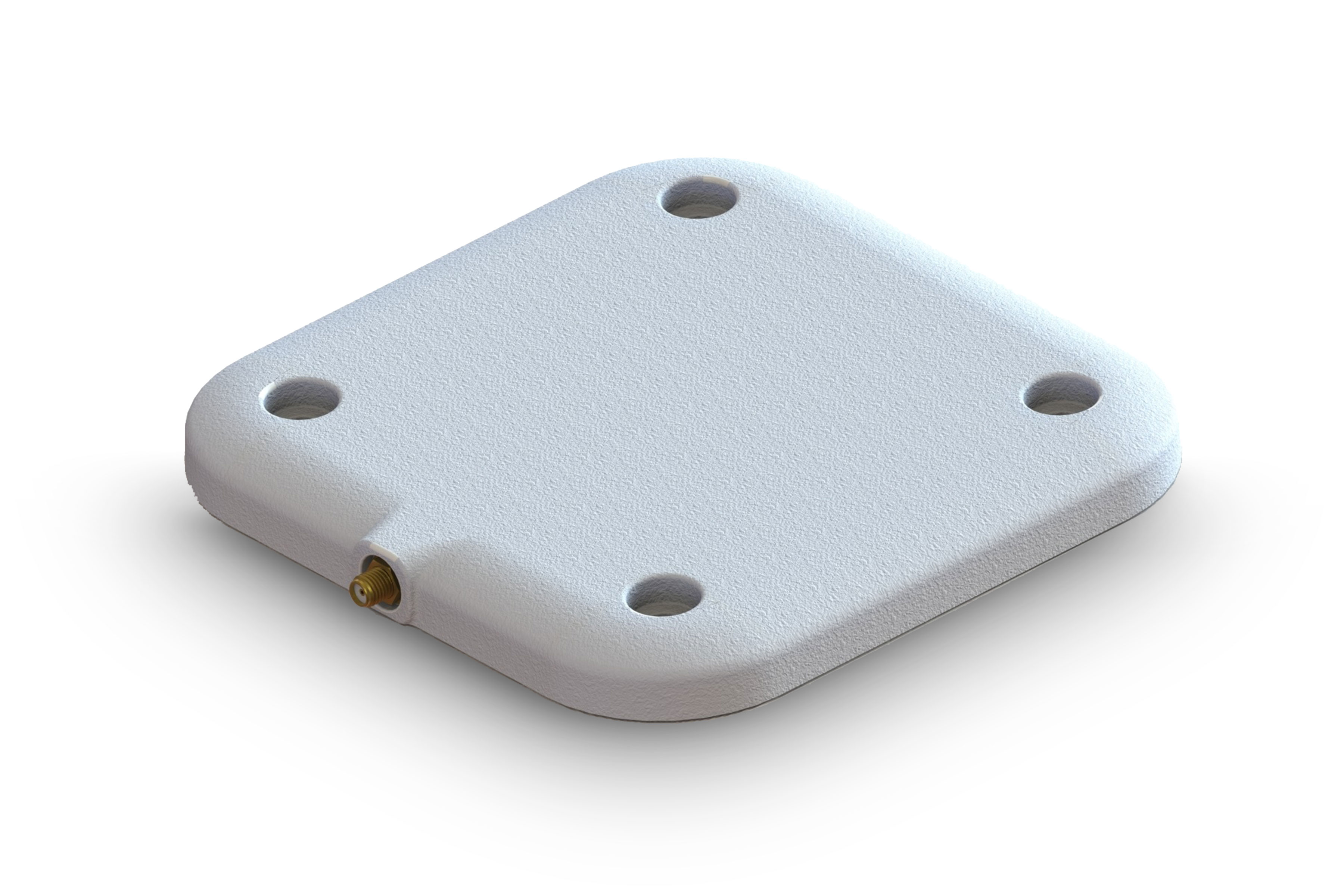

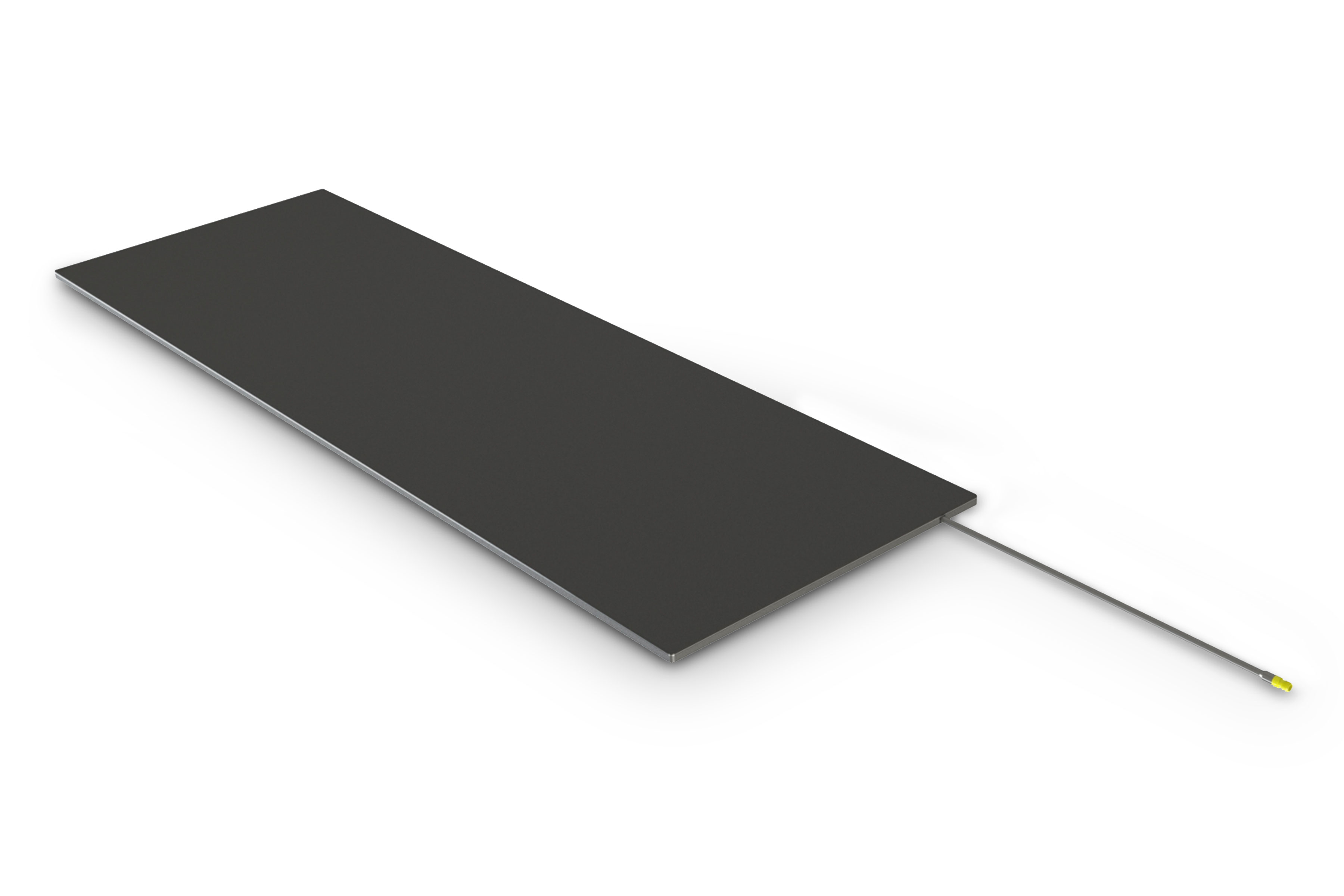

Zebra’s high-tech, connected solutions, combined with InThing’s scalable and resilient sensor platform for RFID and RTLS adoption, allowed Cepheid to strategically overcome the challenges of a lab setting. The system deploys a Zebra FX9600 Fixed RFID Reader at each manufacturing gateway, paired with Zebra's RFID antennas installed on ceilings and walls throughout the lab. These devices create optimal "read zones" where the system automatically detects and identifies materials by their RFID tags. As tagged goods move around the warehouse, readers capture them automatically, eliminating manual reading. This enables Cepheid to track inventory movement—from receiving and stocking to picking and shipping—without errors or bottlenecks.

To make this possible, each item is equipped with a unique encoded RFID tag, printed by Zebra RFID Desktop and Industrial Printers. Using RFID Handheld devices, the Zebra MC3300xR and the RFD40 UHF RFID Sled, each associate performs an enrolled transaction and validates critical inventory data. After the enrolment transaction and RFID tag placement process all the information is automatically synchronized with SAP. This ensures that everyone has access to accurate, up-to-date inventory information without requiring manual entry.

The Zebra Difference: Outcome and Benefits

The successful implementation of the ‘Grab & Go’ system now eliminates more than 28,000 touchpoints and over 7,000 manual transactions per year. Over nine months, it saved 2,300 labor hours across the lab and logistics associates—equivalent to 96 days.

The company's specialists can quickly access chemicals for their research and track them without paperwork, reducing the need for 10,000 material transfer forms. By eliminating extra steps, Cepheid has improved inventory accuracy and increased team productivity. “In less than a year, our productivity savings skyrocketed—by over 1,000%!” notes Healy. Boosted efficiency across all facilities translates into massive cost savings. “At the start of the year, when the project began, we were saving around $10,000 in productivity. By the end, that number had soared past $100,000,” he continues.

Real-time SAP inventory updates mean no more delays, fewer errors and faster compliance while speeding up the test kit development. With 18 RFID gateways across all R&D and Chemistry Manufacturing labs, teams have what they need 24/7, while management can track every item with precision like never before. But this impact goes beyond numbers. Cepheid teams feel re-energized, and the scientists and manufacturing staff feel more motivated since they no longer waste time on administrative tasks.

With solid results and real savings, Cepheid management is planning to expand Zebra’s solution further, including item-level RFID in manufacturing, to achieve faster, more accurate and more accessible molecular diagnostic solutions. At the heart of it all is serving people better. “With high-tech at the core, we’re here to help people,” remarks Beck. “The faster we develop PCR test kits, the faster millions of users will get answers about their health—without the stress and wait.”