Continental Floral Greens builds worker trust and real-time visibility of 1M+ wreaths with Zebra

The company's goal was clear: bring accuracy, transparency, and traceability to seasonal wreath production by replacing manual tracking with an automated, real-time visibility system. To achieve this, Continental Floral Greens adopted a new solution that transformed its process and built unprecedented worker trust.

Zebra Success Story: Continental Floral Greens

Overview: Manufacturing Challenge

Continental Floral Greens aimed to bring accuracy, transparency, and traceability to seasonal wreath production by replacing manual tracking with an automated, real-time visibility system.

Benefits / Outcomes

- 100% accuracy in total wreath count

- 99.7% production approval rate

- 6,000–7,000 wreath productions tracked daily

- Automated flagging of multi-tag anomalies, preventing inflated counts

- Early detection of double-tag anomalies to ensure accurate production counts

- End-to-end traceability of wreath production

- Reduction in the number of rejected wreath counts

- Minimized labor-intensive counting and reconciliation workflows

Customer

Continental Floral Greens

Belfair, Washington/USA

Partner

Industry

Manufacturing

Solutions

About Continental Floral Greens

Every December, millions of families hang festive wreaths on their doors, yet few pause to consider the intricate process that keeps this tradition alive. From the forests where evergreens are collected, through the skilled hands that weave each item, to the stores, and finally, to each home, every wreath travels a remarkable path. At Continental Floral Greens (CFG), this journey takes place over just a few precious months when cedar, noble fir, and other Christmas greens are harvested. In that narrow window, the company produces over 1 million wreaths, running 24 hours a day, five days a week. But until recently, tracking this high-volume operation relied entirely on handwritten tallies.

"Traditionally, Christmas production has been a very manual process, from raw material movement to finished goods transport," notes Steve DeVry, Product & Technology Development Manager at CFG. "We relied on handwritten numbers, names recorded by hand, and wreaths counted manually at every station. The process was error-prone and made it very difficult to trace anything that was either left out or went missing."

CFG needed accuracy and full visibility—without slowing production. That meant replacing manual counting with a system that could automatically track every wreath, tie it to the right worker and station, and flag rejects instantly. Working with Redline Solutions, the company turned to InThing's Work-in-Progress visibility solution, powered by Zebra Radio Frequency Identification (RFID) hardware.

The Challenge

For years, wreath counting at CFG relied on teamwork and trust. Makers set finished wreaths behind them, support workers stacked them in groups of 10 or 15, and someone at day’s end scanned employee barcodes and typed total counts into the system. With over 300 seasonal makers, manually tracking wreath counts became too complex.

Rather than rushing into automation, the team deliberately explored options. “With the entire ROI compressed into a two-month season, we needed a solution we could eventually use beyond Christmas wreaths,” explains DeVry. But the real question was creating trust. CFG’s employees are motivated by a bonus system tied to their daily wreath production, so it’s crucial to have the correct totals counts. “We needed our workers to trust that the solution would accurately record all production data,” notes DeVry. Reconciling thousands of wreaths each day consumed hours of labor and missing or miscounted wreaths resulted in frustrated employees.

CFG connected with Redline Solutions, which supplied the RFID tags and Zebra RFID hardware and introduced InThing to the team. InThing brought the software solution to the table. “Both immediately understood our operational rhythms and the pressure of production running all day with no downtime for tweaks,” DeVry says. Their combined ability to integrate InThing’s Visium platform and Trapeze cloud system with Zebra hardware—and tie them directly into CFG’s production system—made the solution practical and scalable, even though the project was given the green-light in mid-June and production started on October 1.

With 6,000–7,000 wreath introductions per day, we can now pinpoint any issue down to the maker, minute, and tag. If something seems off, we can zero in on the exact timeframe to figure out what happened.

The Solution

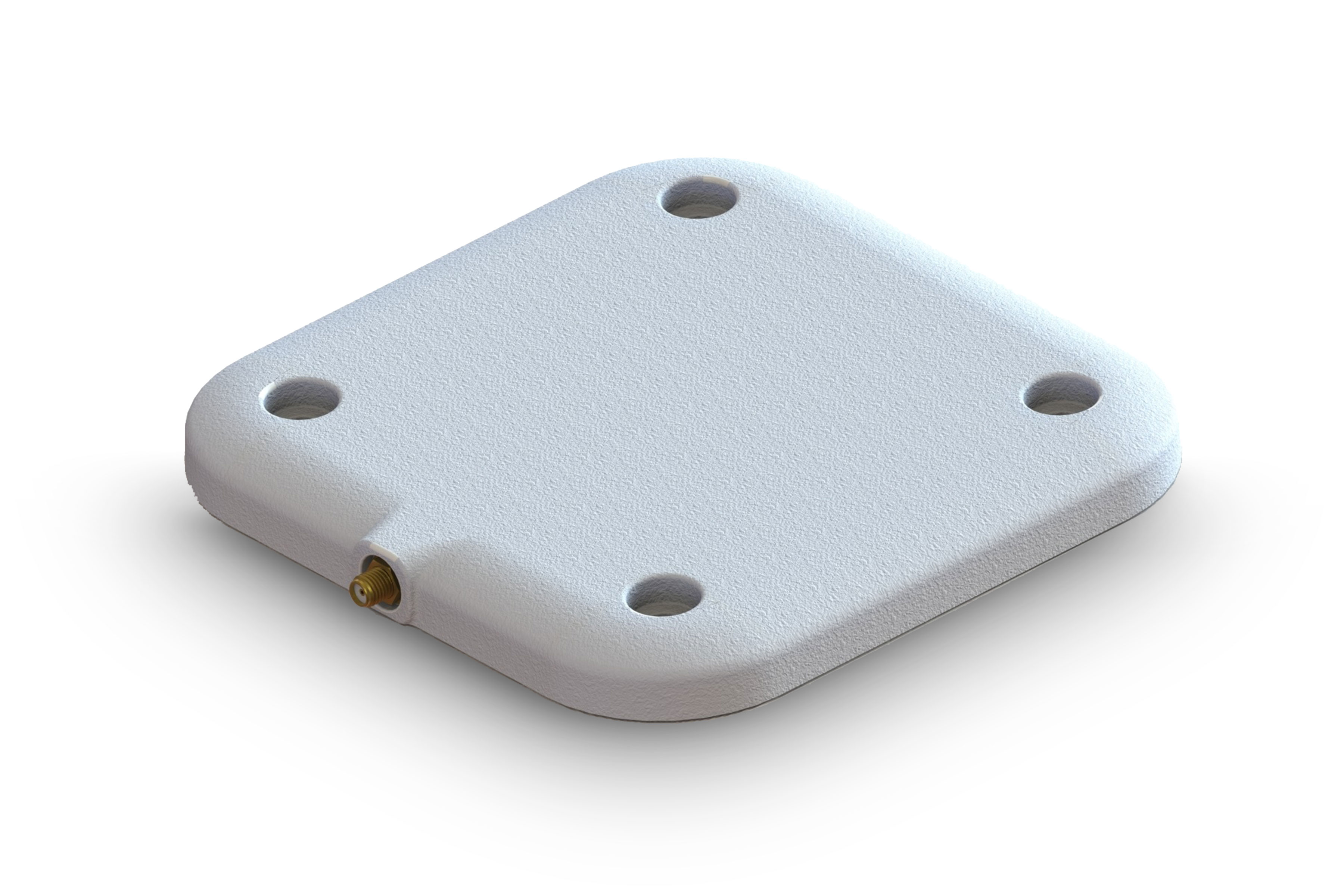

The system architecture is straightforward: each workstation features a mounted Zebra AN520 Ultra-Rugged RFID antenna connected to a Zebra FX9600 Fixed RFID reader, plus a tablet displaying real-time counts via InThing's Visium dashboards. "When a maker finishes a wreath, they attach an RFID tag to the wreath and place it under the antenna," DeVry describes. “The employees’ production metrics update instantly, displaying introduced, accepted, and rejected wreath counts in front of them.” The station flashes the current production count, a simple visual confirmation even if the maker isn't watching the screen.

The wreath then goes onto a conveyor, leading it through an automated weight check. Two additional readers at the quality-control station capture the results in real time: accepted wreaths appear green, rejected ones appear red. Workers can see their performance at any time on their tablet. If there are quality or weight issues with any wreaths, supervisors can use the Zebra MC3300xR mobile computers to trace the rejected wreath back to its maker and station within seconds. “With 6,000–7,000 wreath introductions per day, we can now pinpoint any issue down to the maker, minute, and tag,” says DeVry. “If something seems off, we can zero in on the exact timeframe to figure out what happened and deal with quality issues immediately.”

Behind the scenes, InThing's Visium and Trapeze platforms connect directly to CFG's production system, generating shift reports and real-time data while flagging anomalies like double-tagging. This visibility spans the entire organization. CFG’s data team in Guatemala now audits production in real time through a direct API connection, tracking every wreath's journey from assembly station to finished product and ensuring production counts are always accurate. “I use the InThing Visium dashboards every day for visibility,” DeVry adds. “I can pull reports from previous shifts, check production and reject numbers, and run the whole season in 30 seconds.”

The Zebra Difference: Outcome and Benefits

The new solution gave the wreath makers real-time visibility into their productivity. Now, their counts update instantly on the tablet, letting them see exactly where they stand, even compared with the coworker next to them.

“Visually, it’s a very cool thing to watch,” DeVry says. “Our employees love it. It creates fun, healthy competitiveness, and builds trust.” And when shifts change in the 24/5 operation, they simply scan their employee's RFID badge to reset the station under their name.

One month into the first season using the RFID technology, CFG produced 127,709 approved wreaths with just 459 rejects—a remarkably low 0.3% rejection rate for a high-volume, high-speed line. Automated QC, RFID tracking, and Visium reporting enabled 100% accuracy in total wreath counts and worker payouts, reducing labor-intensive reconciliation to near zero. The automated quality inspection process has also sped up turnaround, moving wreaths from makers to shipping-ready status faster than ever.

The precision also surfaced edge cases that would have gone unnoticed before. “We created a new flag report that triggers when two tags from the same station appear within 1.5 seconds,” DeVry explains. “It is a safeguard against double-tagging or accidental inflation of counts.”

The value of automation becomes undeniable. The RFID system frees wreath makers, supervisors, and support staff from hours of manual tallying, streamlines production, keeps production counts accurate, and eliminates administrative bottlenecks. Now that wreaths are running on a smooth, automated workflow, the CFG team is exploring how the same technology can support other product lines in future seasons.

But the impact has already been felt today. With Zebra’s technology ensuring every wreath is counted fairly, crafted with care, and delivered on time, CFG’s makers can focus on the joy of creating—and customers can welcome the season with something remarkably beautiful. "These wreaths become part of the holiday experience for families all across the country,” DeVry shares. “Knowing our team gets to bring joy to people in this special season means a lot to all of us.”