How to Check If Blood Samples Stayed Chilled Out in Transit

Blood can be a health dashboard for your body. It can show vitamin deficiencies, chemical imbalances and abnormalities. It can help explain away tiredness, enable tailored treatment plans or trigger life-saving processes. Quality and quantity of life can be dramatically altered based on our response to indicators in our blood. With so much at stake, it is imperative that blood testing be as painless as possible. Retesting costs money. It costs time, and in many instances, there is no slack, which means inefficiency in the system can cost lives. (Plus, who really enjoys getting stuck with a needle over and over? Not me – and especially not when the follow-on draw could be prevented.)

That’s why I’m all for eliminating retests. One and done is my style – except for when it comes to marathons, of course.

However, in speaking with healthcare providers, I’ve noticed a trend toward acceptance, specifically the acceptance of retest requests as “normal.” If the lab gets a sample that is questionable for whatever reasons, they essentially kick the order back and the patient has to start over, getting poked yet again to restart the diagnostic process. This shouldn’t be normal. We should do everything we can to stop the waste. This includes stopping the disposal of “questionable” samples.

See, the function of blood is extensive. It moves nutrients, oxygen and waste, fights infection, all within the enclosed human body operating at around 37.5°C. Take it out, and it’s not where it wants to be. First it wants to coagulate, to reseal the body to prevent attack from bacteria and unwanted visitors. Then, as it contains living cells, it begins to denature and die.

It’s why there are very specific temperature requirements to which you must adhere when transporting pathology samples, and they may or may not be the same as the blood products intended for transfusions. Though most cold chains and labs have quality monitoring/quality control systems in place, as well as RFID-based tracking systems, not all actively monitor the temperature inside blood transport bags. They may only keep tabs on the surrounding climate. So, I think it’s worth calling out the temperature sensitivity of blood samples and the potential consequences if no one can tell whether a sample has been compromised, including regulatory and internal policy compliance.

The whole team is up against the clock to get each and every sample to the testing facility and tested without it getting damaged by overly hot or cold temperatures on route (as defined by AABB Standards and 21 CFR 640). Zero to four hours is the typical window allowed from bleed to test!

Get it wrong and the sample becomes useless. At best, it’s untestable and binned. At worst, the lab technician will deliver an incorrect result leading to misdiagnosis and treatment. Whatever the outcome, it comes at a cost.

That’s why you should never strike temperature sensors from your spend plan due to “the cost.”

First off, they are very affordable and easy to include with every transported blood sample. Second, the cost of going to court to resolve a malpractice suit is far higher than preventing such an incident in the first place.

It’s not uncommon for one to wonder if a blood sample changed temperature during transit. Perhaps the journey took longer than usual on a hot day and its insulated container began to warm. Or maybe things dipped out then back into the safe temperature zone. The blood could be damaged without anyone even knowing. Or it could be fine, but someone worried about safety uses a subjective ‘feel’ test to check the temperature and decides that a sample feels warm and it’s not risking an incorrect result, so they toss it. Either way, not good.

Temperature (and Inventory) Tracking at Its Simplest

Because the quality of blood and other bodily fluid samples is so very important in defining and delivering treatment programs, Zebra has developed a solution in conjunction with independent software vendors (ISVs) to validate that you have a temperature-controlled transportation system in place capable of delivering a test-worthy samples to the lab in a timely manner. (It’s currently available in the UK and Europe.)

The solution can be tailored to meet your varying needs, but there’s one very cool setup that I want to call out. You can put a tray of blood vials in a purpose-built insulated blood transport bag designed specifically for temperature-controlled shipment. (It looks a lot like the bag used to keep pizzas hot while out for delivery.) Each vile is identifiable when matched to a database because each is tracked with a barcode label, written record and RFID tag starting at the time of collection. Having the barcode and RFID label immediately cuts out mistakes from illegible handwriting, or mistyping labels, making the information system it’s feeding the single source of truth and the written record more of a redundancy.

The vials are then tracked using a passive RFID system that reads as the bag is placed into a specially designed reading tray prior to leaving the hospital, clinic or surgery centre then scanned again as the tray arrives in a van at the lab before a third and final read again inside the lab upon receipt. The unique identification code on each sample links it to the patient electronic medical record (EMR) and also anonymously to software which shows a colour-coded dashboard should there be an anomaly such as an unexpected or missing sample. The driver has no access to personal data but can see if they are missing a sample, and they can also prove that they made a delivery within the specified time window.

With everything captured and recorded in real time, the lab has visibility of where the samples are in transit and what tests are needed so they can prepare in advance. The solution also helps ensure the right sample gets to the lab in the right time.

But how can you be sure it wasn't denatured by a blast of heat along the way? That’s easy: an electronic temperature sensor quietly sits in a pocket in the insulated blood sample transport bag and systematically tracks temperature data every minute.

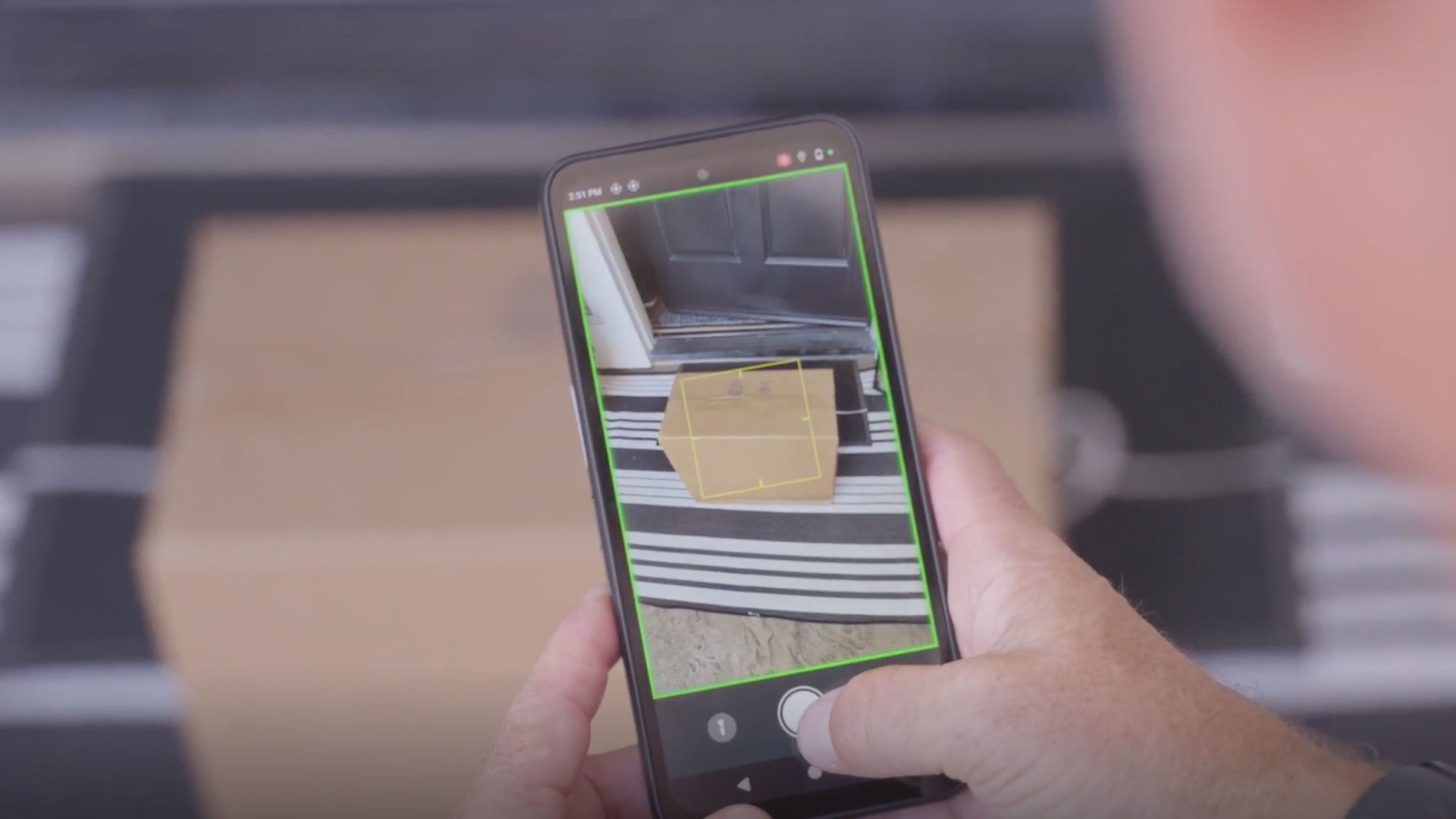

When the blood arrives at the lab, the person who physically receives the bag of vials places it into an RFID reader tray in a blood hatch with a 'bridge' incorporated nearby. The bridge receives logged data from the temperature sensor and sends it up to the cloud where it is collected by an application programming interface (API) and delivered to sample tracking software that’s running on internet-enabled devices, such as handheld mobile computers or tablets.

A lab technician then officially checks in the entire lot of received blood, first checking the dashboard to ensure there are no missing or incorrect samples based on the advanced notice of inbound inventory. They then batch check the temperature of each vial, which was logged each minute starting at the time of collection and continuing during transport then aggregated in a dashboard graph on mobile and desktop devices. If they confirm the blood has remained within safe parameters and is test ready, then they move it to the next step in that process. If they spot an anomaly, such as a temperature dip or peak on the graph, they can then order an urgent retest.

This fast validation process helps cut the risk of testing a damaged sample and reduces the risk of incorrect results and treatment. Plus, the sooner the patient can resubmit samples, the sooner they (and their physician) can get some answers – and answers help save lives.

Along those same lines, the addition of temperature sensors to every pathology sample transport bag adds a layer of safety to testing procedures, creating a checks and balances system that gives everyone confidence that things were done by the book and the results can be trusted. It also provides a paper trail should there be any allegations of incorrect procedure, giving patients peace of mind that their sample wasn’t comprised and protecting hospitals from litigation.

Technically Speaking

If this all sounds well and good, you might be wondering how you can get this type of tool built into your blood collection, transport and testing processes (and what it will cost you).

First off, let me tell you that the hardware (temperature sensors + RFID system) and software I mentioned are available today and field tested. Zebra has been working with the ISVs involved to make sure all components are compatible with one another and will consistently operate as one – as if they were built for the same company as a single platform system.

The even better news is that because this is a solution coming out of the Zebra ecosystem, you are not going to be the one who must lead the deployment. We’ll steer it, with you co-piloting. We’ll involve your IT experts, lab technicians, supply chain operations managers, lab managers and quality control managers in the process to make sure the technology is supportive of your existing procedures and compliant with all policies. We’ll also work together to design the system in a way that fits neatly into your tech stack and minimizes disruption to workflows. Our goal is to speed up sample testing, not slow it down.

The one (or few) thing(s) your team will have to do is help us scope out the project so we’re building the right RFID tracking system to eliminate the manual processes and help highlight anomalies in your inventory and workflows. Once the fixed RFID reader infrastructure is installed – or handheld RFID readers rolled out – and the proper software licenses are purchased, all your front-line team will need to do is print and label pathology samples, which they already do anyways. From there, we’ll make sure all the blood transport bags are equipped with the temperature monitors and put into service, and you will be good to go.

Don’t Forget!

Temperature-sensing RFID tracking solutions are not just limited to healthcare. Any vertical where products have to remain within a specific temperature range, be it pharmaceuticals, food or vaccines, can be managed utilising this solution. Checking process adherence, maintaining safety standards, protecting products and people is a universal best practice.

For more information about temperature tracking solutions, please contact your Zebra representative or visit our website.

###

Related Reads:

Lorna Hopkin

Lorna Hopkin is Product Marketing Advisor at Zebra Technologies with responsibility for Zebra healthcare solutions and advanced location technologies. Lorna joined Zebra in August 2018 as part of its acquisition of rugged tablet specialist Xplore Technologies.

Lorna is a chartered marketer and has two and half decades’ experience across a wide range of industries. At Zebra, she has launched a variety of products into the healthcare space and other verticals.

Lorna is a tireless advocate for health and fitness at Zebra and in her spare time participates in Ironman competitions and enjoys writing about her experiences at https://theordinaryironman.com/

![[Category, Subcat or Product] Representational Image 16:9](/content/dam/zebra_dam/global/zcom-web-production/web-production-photography/newsroom/2026-images/photography-web-newsroom-featured-03-16x9-en-us-013026.jpg.imgo.jpg)