What Are Machine Vision Cameras?

A machine vision camera is a special type of camera designed to "see" and understand images the way humans are able; these types of cameras are called “smart cameras”. Smart cameras are used in a range of industries to help machines or computers make decisions based on what they see. Machine vision employs smart cameras to capture visual information from the surrounding environment, under potentially challenging lighting conditions, and provide high-resolution images with precise color accuracy and optimal resolution.

The acquired images are then processed using sophisticated algorithms and software, which analyze the visual data to detect defects, identify objects, measure dimensions, extract features or recognize patterns. Smart camera technology commonly incorporates special sensors and lenses to ensure they capture accurate and detailed images. By leveraging specialized optics, machine vision systems can optimize image quality, minimize distortions and ensure consistent and reliable results. This allows machine vision to tackle complex visual tasks, including quality control, inspection and measurement. Machine vision smart cameras are key tools in various industries, including manufacturing, vision-guided robotics, healthcare and security.

Can You Use Any Camera for Machine Vision?

Not all cameras are suitable for machine vision applications. While regular cameras may capture images for general purposes, machine vision cameras are specifically designed with features that make them more suitable for industrial and automation applications.

Machine vision cameras are purpose-built for industrial and automation applications. They incorporate advanced features such as high-speed image acquisition, low latency, precise synchronization and specialized optics—elements necessary for optimal performance and accuracy in demanding visual inspection and analysis tasks. Moreover, machine vision cameras offer advanced features like triggering capabilities, precise exposure control and robust software integration for seamless integration with other components of the machine vision system.

These specialized cameras are designed to withstand harsh operating conditions, including varying lighting conditions, temperature extremes and vibration, ensuring consistent and reliable image capture. Careful consideration and evaluation are therefore essential when choosing a camera for machine vision applications to ensure compatibility and achieve optimal results. By selecting the appropriate machine vision camera, businesses can optimize the accuracy, efficiency and reliability of their visual inspection, quality control and automation processes.

How Is a Machine Vision Camera Different from a Normal Camera?

A machine vision camera, also known as an industrial camera, is designed specifically for applications in machine-vision systems. While there are similarities between a machine vision camera and a normal camera, there are several key differences.

- Purpose: Machine vision cameras are purpose-built for use in industrial and automation settings for applications such as inspection, quality control, robotics and object recognition. Their main purpose is to capture images or videos that can be processed and analyzed by computer vision algorithms. On the other hand, normal cameras are designed for general-purpose photography and video recording.

- Image quality: Machine vision cameras prioritize factors like image quality, consistency and reliability for precise analysis and inspection tasks. They often have higher resolutions, faster frame rates and lower noise levels, allowing them to capture detailed images in real-time or high-speed applications. Machine vision cameras may also incorporate features like high dynamic range (HDR) imaging, low noise sensors, advanced triggering mechanisms and precise exposure control to ensure accurate and consistent image capture in challenging industrial environments. Normal cameras, such as those found in smartphones or digital cameras, prioritize image quality and user experience.

- Frame rates: Industrial vision cameras exhibit significantly higher frame rates compared to conventional cameras. Depending on the camera's resolution, industrial vision cameras can capture several hundreds or thousands of images per second, a capability that sets them apart from ordinary cameras. The disparity in frame rates between the two types of cameras underscores the specialized nature of industrial vision cameras, which are designed to meet the rigorous demands of industrial applications requiring rapid image acquisition and analysis.

- Interface and connectivity: Machine vision cameras typically feature industry-standard interfaces like Gigabit Ethernet, USB or Camera Link, which facilitate seamless integration with other machine vision components. They offer specialized interfaces, synchronization capabilities and compatibility with industry-standard protocols. Designed to work with specialized vision software and hardware, machine vision cameras enable easy data transfer and control, providing the foundation for reliable and high-performance machine vision applications. In contrast, normal cameras typically have consumer-oriented interfaces like USB, HDMI, or wireless connectivity for direct interaction with users.

- Durability and reliability: Machine vision cameras are built to withstand harsh industrial environments, including extreme temperatures, vibrations and dust. They are often housed in rugged enclosures, have an IP rating and feature industrial-grade components to ensure long-term reliability and stability. Normal cameras are generally not designed for such demanding conditions and may be more susceptible to damage.

- Flexibility and customization: Machine vision cameras offer greater flexibility and customization options to meet specific application requirements. They often provide programmable features such as exposure time, trigger modes and region of interest (ROI) selection. These functionalities enable precise control over image acquisition and processing. Normal cameras, while offering some manual settings, are generally more focused on providing automatic features for ease of use.

It's important to note that with advances in technology, some modern consumer cameras may incorporate machine vision capabilities, blurring the distinction between the two categories. However, in general, the differences outlined above still hold true for traditional machine vision cameras and normal cameras.

What Are the Different Types of Machine Vision Camera Formats?

Machine vision cameras come in various formats, each suited to different application requirements. Some of the most common types of machine vision camera formats include:

- 2D Cameras: These cameras capture images in two dimensions, representing the visual scene as a flat image. 2D cameras are widely used in machine vision systems for various tasks, including object detection, pattern recognition, positioning and alignment, measurement and optical character recognition (OCR), among others. They provide spatial information about the objects or scenes they capture, allowing for the analysis and processing of the images to extract valuable data for inspection and quality control applications.

These 2D cameras can vary in resolution, pixel size, sensor type, frame rate and connectivity options. They often use technologies such as Charge-Coupled Device (CCD) or Complementary Metal-Oxide-Semiconductor (CMOS) sensors to convert light into electrical signals, which are then processed to generate 2D images. Machine vision 2D cameras play a fundamental role in many industrial and commercial applications, enabling automation, improving accuracy, enhancing productivity and ensuring quality control in various industries such as manufacturing, logistics, healthcare and robotics.

- Area Scan Cameras: In the context of machine vision, the terms "area scan cameras" and "2D cameras" are often used interchangeably. However, "2D" is a general term indicating two-dimensional imaging, while "area scan cameras" are a specific type of 2D camera that capture images by scanning an area pixel by pixel and providing high-resolution images.

Area scan cameras are designed to capture a single image of the entire field of view at once, as opposed to line scan cameras that capture images line by line. They utilize a sensor that consists of an array of pixels arranged in rows and columns, like the image sensors found in common digital cameras.

When an area scan camera captures an image, each pixel in the sensor array records the intensity of light falling on it, resulting in a complete 2D image that captures the intensity or color information for each pixel in the field of view. This image can then be processed by machine vision software to perform various tasks such as object detection, metrology and measurement, alignment and positioning and visualization and monitoring purposes. One of the key advantages of area scan cameras is their ability to capture still images of a complete scene, making them suitable for applications that require a snapshot of the entire field of view. These cameras are commonly used in systems that address quality control and inspection, as well as for robotics, packaging and other industrial automation applications.

- 3D Cameras: 3D machine vision cameras—also known as 3D vision cameras, range cameras or depth cameras—are a type of camera specifically designed to capture three-dimensional information about objects or scenes. Unlike traditional 2D cameras that capture flat images, 3D cameras use advanced technologies to measure depth (e.g., Z-axis dimension) in addition to height and length, and create a three-dimensional representation of the object's shape and spatial characteristics. They are used in tasks such as 3D inspection and quality control, robot guidance and bin picking, in addition to dimensional measurements and metrology. These cameras leverage different techniques to capture depth information, including stereo vision, time-of-flight (ToF), structured light and laser profile scanning. Each technique has its own principles and advantages, but the common goal is to generate a point cloud or depth map that represents the three-dimensional structure of the scene.

Machine vision 3D cameras find applications in a wide range of industries and fields. They are used for tasks such as 3D object recognition, robotic guidance, dimensional measurement and metrology, inspection of complex surfaces and more. Their ability to capture depth information enables these cameras to provide valuable insights for accurate object localization, shape analysis and spatial understanding. By incorporating 3D machine vision cameras into vision systems, businesses can achieve enhanced precision, improved automation and increased efficiency in various industrial applications, such as quality control, vision-guided robotics (VGR), industrial automation, healthcare imaging and others.

- Line Scan Cameras: Machine vision line scan cameras are a specific type of camera used in machine vision installations for applications that require high-speed imaging and inspection of continuous or moving objects, for example, items on a conveyor belt. Unlike traditional area scan cameras that capture an entire image at once, line scan cameras capture images line by line in a sequential manner.

Line scan cameras consist of a linear array of photosensitive elements (pixels) that are arranged in a single row. As the object moves past the camera, each pixel captures a portion of the object's image. These sequential lines are then combined to form a complete image. The continuous scanning process of line scan cameras enables them to capture high-resolution images of fast-moving objects without motion blur.

Line scan cameras are commonly used in industries such as manufacturing, food processing, pharmaceuticals, printing and postal sorting. They can be applied to perform tasks like detecting defects, measuring dimensions, reading barcodes or text and high-speed inspection of printed materials. By incorporating machine vision line scan cameras into automated systems, businesses can achieve precise and reliable inspection capabilities, ensuring product quality, reducing waste and enhancing overall efficiency in production and quality control processes.

- Thermal Cameras: Thermal cameras, also known as infrared cameras or thermal imaging cameras, are widely used in machine vision for various applications that require capturing and analyzing thermal information. Unlike conventional cameras that capture visible light, thermal cameras detect the infrared radiation emitted by objects based on their temperature. Thermal cameras contain sensors that can accurately capture and measure the surface temperature of objects without physical contact and within their field of view, making them ideal for applications such as monitoring industrial processes. The captured thermal images represent the temperature distribution across the scene, with different colors or shades representing variations in temperature.

In machine vision applications, thermal cameras are particularly useful for tasks that require temperature analysis, such as monitoring heat patterns or identifying hotspots and temperature anomalies. By utilizing machine vision thermal cameras, businesses can perform heat mapping to identify areas of excessive temperature, detect potential malfunctions or equipment failures and implement proactive measures to prevent damage or accidents. The ability to visualize and analyze thermal information enables early detection of temperature-related issues, leading to improved safety, enhanced efficiency and optimized operational performance in a wide range of applications and environments, including building inspections, electrical inspections, manufacturing processes and security surveillance.

- GigE Vision Cameras: This type of machine vision camera uses the Gigabit Ethernet (GigE) Vision interface standard for image data transfer. It defines a standard method for transmitting high-quality images and control data over Gigabit Ethernet networks. GigE Vision enables seamless integration and interoperability between GigE cameras and other vision system components, such as computers, software and peripherals.

GigE Vision cameras are specifically designed for applications that require high-speed image acquisition, real-time data transfer and remote-control capabilities. The GigE Vision interface provides several advantages for machine vision systems. It enables long cable lengths, allowing cameras to be placed at a considerable distance from the host computer without sacrificing image quality or data transfer speed. This flexibility is especially beneficial in industrial environments where cameras need to be deployed in different locations or integrated into complex systems and maintain fast, reliable image capture capabilities.

Additionally, GigE Vision cameras are compatible with standard Ethernet infrastructure, making them easy to integrate into existing network setups and thus a popular choice in industrial automation, robotics, quality control and many other machine-vision applications. They can be connected to a Gigabit Ethernet switch or directly to a host computer with a GigE Vision-compatible network interface card (NIC). The cameras leverage the widespread availability and reliability of Gigabit Ethernet technology, eliminating the need for specialized cabling or dedicated networks, as they can utilize the existing Ethernet infrastructure commonly found in industrial and commercial settings. Machine vision systems equipped with GigE Vision cameras can capture high-resolution images and video streams, perform real-time image processing and employ various software tools and libraries designed for GigE Vision compatibility.

These are just some of the common machine vision camera formats; there may be other specialized formats available depending on the manufacturer, specific industry requirements and applications.

How Do Machine Vision Cameras Improve Quality Control Processes and Enhance Manufacturing Efficiency?

Machine vision cameras play a crucial role in improving quality control processes by automating tasks, increasing precision and repeatability and enhancing speed and throughput. By automating inspection tasks, these cameras capture high-resolution images or video streams of products and components, which are then analyzed using advanced computer vision algorithms. This automated approach ensures faster and more accurate defect detection, gaging, guidance, measurements and verification compared to manual inspection methods.

Machine vision smart cameras provide flexibility in complex automation tasks, simplifying robotic pick-and-place applications and reducing manufacturing costs. They can more readily detect defects that might be overlooked by human inspection.

Factors like environment, lighting, process speed, mounting location and part size all influence camera selection, as do considerations including image sensor characteristics, digital interface standards, cable requirements, built-in processing features, reliability and ease of integration.

Technological advancements continue to introduce and refine features like deep learning, 3D imaging, polarization imaging and event-based vision, expanding potential applications in various industries. Machine vision cameras have significantly improved quality control processes and enhanced manufacturing efficiency by providing high-resolution imaging, real-time data analysis and automated inspection capabilities, leading to faster and more accurate defect detection and product validation. And as the pace of innovation accelerates, staying informed about the latest sensor technologies, interfaces and computing trends is crucial for selecting the most suitable camera system and planning for future process improvements.

How Do Machine Vision Cameras Contribute to Process Automation and Optimization in Various Industries?

Machine vision solutions employ advanced imaging technologies and intelligent algorithms, and have been widely adopted to automate and enhance production processes and enable accurate, efficient industrial automation. Machine vision cameras comprise an integral part of many vision systems, capturing high-quality images, then analyzing and interpreting visual data for automated inspection, quality control and assurance, process monitoring, traceability, as well as data analytics and decision-making. Integration of machine vision cameras enhances productivity, reduces human error and improves overall operational efficiency in diverse applications.

In manufacturing industries, machine vision cameras play a crucial role in quality control by inspecting products for defects, checking for dimensional accuracy, identifying errors in assembly and ensuring adherence to specifications. This helps manufacturers maintain high-quality standards, reduce waste and minimize production costs.

In logistics and warehousing, machine vision cameras contribute to efficient inventory management and logistics operations. Machine vision cameras excel at swiftly capturing precise data from barcodes, labels and package contents, as well as facilitating accurate identification, tracking and sorting of items. With the ability to rapidly capture and analyze information, these cameras enable seamless inventory management, optimized logistics operations and improved overall productivity in the supply chain. By leveraging the capabilities of machine vision cameras, businesses can streamline order fulfillment, minimize errors and ultimately elevate customer satisfaction.

In the retail sector, machine vision cameras and image recognition algorithms help automate checkout processes by, first, eliminating the need for manual scanning, and then identifying products, calculating prices and processing payments to enable automated checkout processes. Automated checkouts are revolutionizing the retail experience, reducing wait times and improving operational efficiency for retailers to enhance the overall shopping experience for both customers and retailers.

In healthcare, machine vision cameras can improve the accuracy and speed of medical diagnoses, reduce human error and enable healthcare professionals to make more informed decisions. They help automate quality control processes to detect defects and ensure adherence to regulatory standards. They can read and interpret barcodes and other identifiers on medication packaging to ensure that the right medication is given to the right patient. The cameras can also facilitate remote monitoring and telemedicine applications, capturing and transmitting high-quality images to healthcare professionals for timely treatment decisions, enhancing access to healthcare services and improving patient outcomes. Overall, machine vision technology has the potential to revolutionize the healthcare industry by improving patient outcomes, reducing costs and increasing efficiency.

Overall, machine vision cameras have revolutionized various aspects of business operations, driving automation and improving accuracy and efficiency across multiple industries. By leveraging their vision capabilities, businesses can optimize processes, improve quality control and gain a competitive edge in the market.

What Is the Role of a Machine Vision Camera in Various Machine Vision Applications?

In today's business landscape, machine vision is playing an increasingly pivotal role, providing numerous benefits across various sectors. Here, we delve into some notable applications that highlight the versatility and value of machine vision cameras:

- Retail: Machine vision cameras are used in automated checkout systems, allowing for efficient scanning and identification of products without the need for manual input. These cameras can quickly recognize barcodes or other product identifiers, ensuring accurate and speedy transactions. In retail environments, the cameras monitor shelves and product displays to ensure proper stocking, organization and inventory control. These cameras can detect empty spaces, misplaced items, or low stock levels, triggering automated alerts or reordering processes to maintain optimal product availability.

- Warehouse and Distribution: Machine vision cameras are essential for automated sorting systems in warehouses and distribution centers. These cameras capture images or read barcodes to identify and track packages, enabling efficient sorting and routing of items to their designated locations. These cameras inspect incoming and outgoing goods for quality control purposes. They can identify damaged or defective items, ensuring that only high-quality products are dispatched to customers and minimizing returns or rework.

- Healthcare: Machine vision cameras are used in medical imaging systems such as X-ray, ultrasound, or endoscopy. These cameras capture detailed images of the human body, aiding in diagnoses, surgical procedures and treatment planning. Machine vision cameras also play a vital role in laboratory automation, assisting in tasks such as sample identification, sorting and analysis. These cameras can accurately read barcodes, analyze test results, or identify specific characteristics of samples, improving efficiency and accuracy in laboratory processes.

- Manufacturing: These cameras are extensively used in manufacturing for quality inspection purposes. They can detect defects, measure dimensions and identify inconsistencies in products during the production process. This ensures adherence to quality standards, reduces scrap or rework and enhances overall product quality. Machine vision cameras provide visual feedback to vision-guided robotic (VGR) systems, enabling precise positioning, manipulation, or assembly of components. These cameras help robots identify objects, locate targets and perform complex tasks with accuracy and efficiency.

- Transportation and Logistics: Machine vision cameras are used in automated package sorting systems in transportation and logistics facilities. These cameras read barcodes, capture images, or extract information from shipping labels to sort packages accurately and route them to the correct destinations. Vision camera technology also plays a role in vehicle inspection processes, such as automated license plate recognition or identifying container numbers on trucks. These cameras assist in security, regulatory compliance and efficient management of vehicle fleets.

In summary, machine vision cameras are integral to these verticals and many others, in helping enable more robust automation, quality control, efficiency and improved accuracy in processes, ultimately contributing to enhanced productivity, cost savings and customer satisfaction.

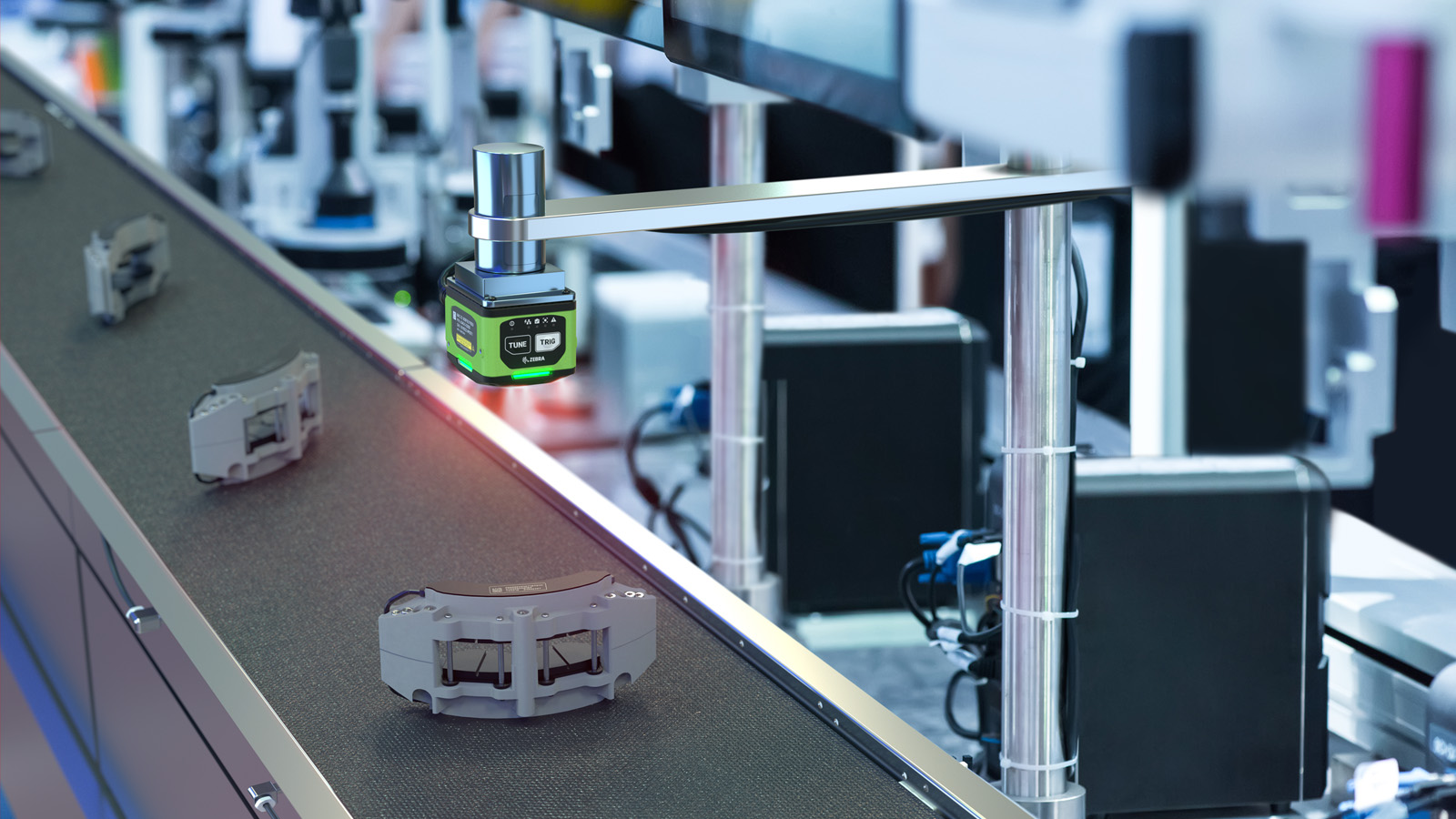

How Can Zebra’s Machine Vision Cameras Help Accelerate Productivity and Optimize Operational Effectiveness?

Zebra Technologies offers cutting-edge machine vision camera technology that is designed to reduce production defects, enhance throughput and improve overall efficiency—all of which help optimize warehouse or manufacturing operations. With state-of-the-art smart cameras and powerful vision software tools, businesses can extend their scanning capabilities and easily set up, deploy and run vision applications. Zebra also offers upgradeable features to ensure scalability to meet evolving business challenges, providing businesses across various industries with flexibility as needs may change. Whether a business requires simple or complex inspections on its production line, Zebra offers a range of smart sensors and machine vision cameras that deliver unmatched precision. You can experience the benefits of our innovative machine vision solutions and take your operations to the next level.