How You Can Harmonize Inventory Chaos through AI Augmentation

As we get deeper into the 2022-2023 NFL Football season I find myself spending several hours watching my favorite team – my colleagues at Zebra – do what they do best: track professional football players’ on-field movements using Zebra Motionworks™ technology. These Zebras have spent weeks revving up their analysis and insights of all the data captured from players’ equipment during games so that you and I can access all the Next Gen Stats we could ever want on game day. They’re even helping NFL teams capture player data during practices as part of Zebra’s role as "The Official On-Field Player-Tracking Provider" of the NFL.

As an American football fan, I'm amazed by all the information that can be gathered from this type of RFID tracking technology. Besides being cool, we can see data points about ball velocity, player speed and movement patterns that weren't even possible before. Players, coaches and trainers also enjoy detailed views of players' health and performance. This data trove revolutionizes how staff members evaluate players, even during practices, and transforms game plans.

NFL coaches are always looking for the edge – to be more competitive in a game of inches. In a recent Chalk Talk podcast, Super Bowl-winning former NFL coach (and now Fox Sports analyst) Sean Payton explained how technology has transformed football. He shared how technology is a simple solution to many challenges, the data points his coaching staff regularly looked at, and the insights they gained.

"From the training room to the classroom to the field, how we train our athletes – all of that has been impacted by the advancements in technology."

Sean Payton, Super Bowl-winning former NFL coach

What am I telling you this? What does the NFL’s use of RFID and AI have to do with the current state of retail and consumer packaged goods (CPG) supply chains?

Just like the NFL, the traditional retail and CPG playbook doesn't work anymore, and companies are using new data sources to gain that edge.

"Data that wasn't even captured before is now captured," according to Sivakumar Lakshmanan, vice president and general manager of Zebra’s IT business and the former CEO of antuit.ai, which is now part of Zebra Technologies. But this data capturing goes beyond the need to capture data for data's sake – intelligent systems use the data to drive inventory decisions. Wine companies can use weather data to plan their shipments to avoid excessive heat, and health companies can utilize pollen data to place allergy medicine in suitable locations. And that’s just the start.

Inventory Chaos

The past few years have been chaotic, to say the least, with retail and CPG companies experiencing both inventory shortages and gluts. The IHL Group recently published a study that put the total cost of overages and shortages at nearly $2 trillion – up 12.7% since 2020 – with$1.235 trillion of this cost due to out-of-stocks and $758 billion due to overstocks.

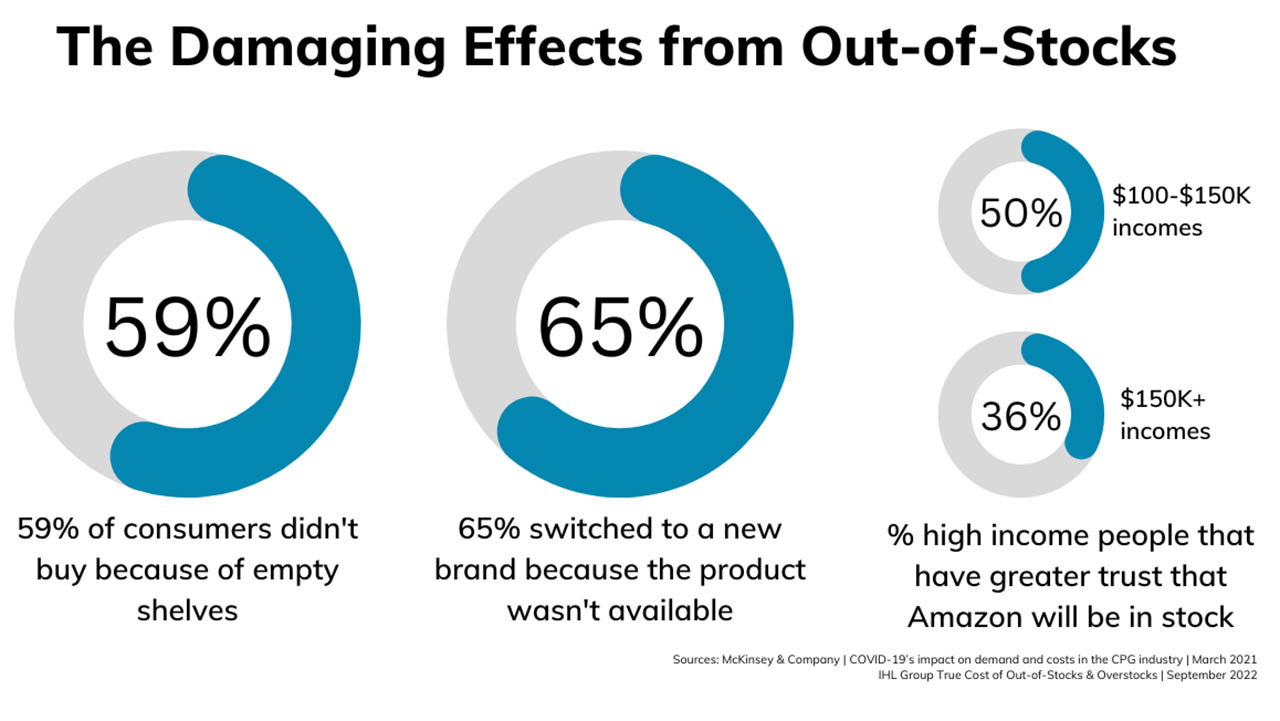

But the secondary effects are even more painful. When cash is locked up in inventory, companies don't have the freedom or agility to make the necessary investments. And the cost of being understocked is not limited to lost sales. According to various studies, the primary reason consumers try another brand is availability. That may not be a surprise. It’s probably not a shock that “empty shelves” are the primary reason consumers leave a store without purchasing, either. But did you know the retailer that most higher-income shoppers are turning to (because of lack of trust in others) is Amazon?

This is a call to action – and specifically a call for change – from the first mile in the retail value chain through the last. Retailers and CPG companies that implement new technology “solutions” without changing how they’re using technology aren’t solving anything. They’re not even putting a band-aid on this deep wound. They’re preventing it from healing.

A Trifecta of Innovation

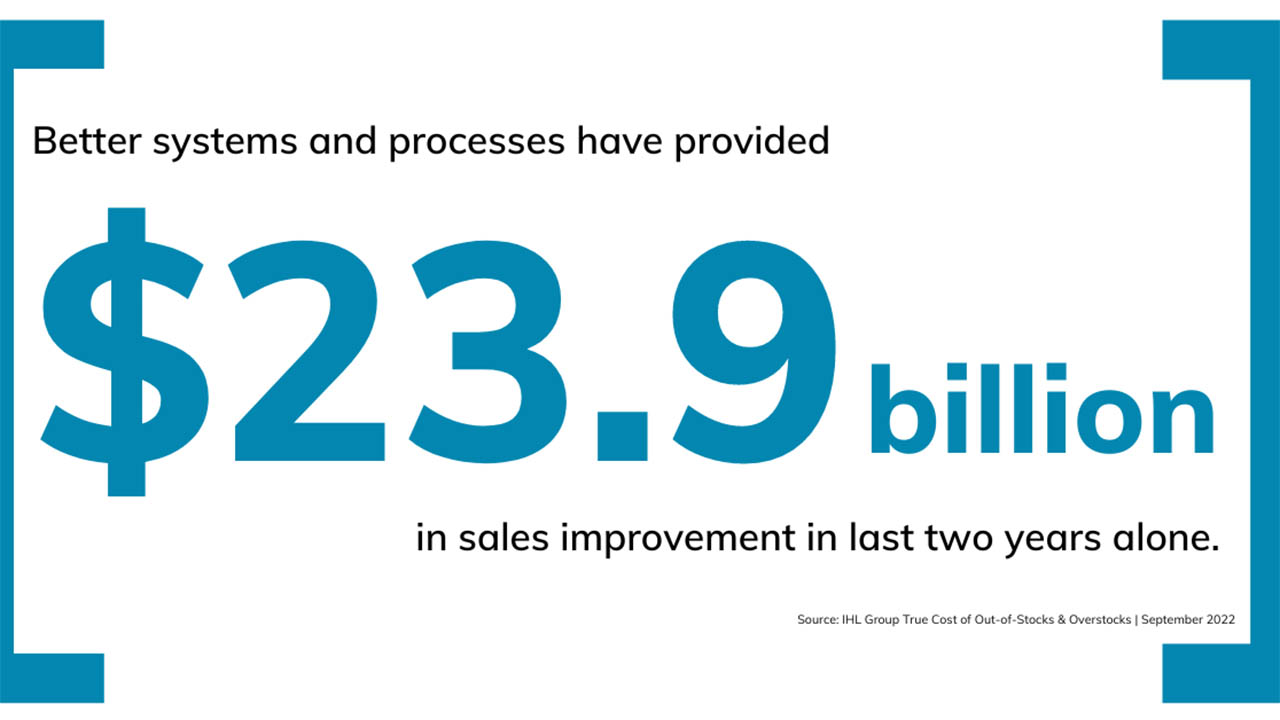

Look, there’s no doubt technology is key to solving tomorrow's problems. It has made a significant impact in the recent past. Due to companies’ technology investments, labor productivity grew by 2.2% annually between 2020 and 2021, up from a 0.9% average annual growth from 2011 to 2019. And in IHL Group's beforementioned report, "Better systems and processes have provided $23.9 billion in sales improvement in the last two years alone."

And, yes, AI, cloud, and software-as-a-service (SaaS) technologies are a big reason for these gains.

As my colleagues and I have discussed before, cloud computing increases processing power while lowering costs. SaaS subscriptions force software providers to be more accountable for their promises. And AI solutions decipher data at escalating speed, scale, and sophistication. It's a trifecta of innovation.

Despite the excitement, AI technologies alone are not a magic bullet. After all, many AI projects fail to deliver expected results, and transformative results require human interaction with the AI system. Business users don't have to know the details behind how the AI works, but they should conceptually understand what it's doing and how to use it. It's like someone telling you Big Data is the solution to all problems, then never following up with how to use the actual data thrown in front of you. Oh wait, that happened.

But this article isn't about AI benefits – it's about how data and AI can transform your thinking and approach as analytics did in baseball, football, soccer, and other sports.

Transformation through Augmentation

The biggest challenge that CPG companies face today is anticipating consumer demand. Seventy-six percent of supply chain leaders are saying they are facing greater and more frequent disruptions than three years ago. Supply chain issues compounded by shifting buying behavior have inventory whipsawing from shortages to overages. Digitizing and digitalizing an entire supply chain can cost tens of millions of dollars and take 3-5 years. And this investment doesn't include the costs of adding new production and storage facilities. Businesses can't wait that long and spend that much to see change.

Using AI to augment systems is a viable alternative. System augmentation is not new, but before, it added new features and capabilities onto a core ERP solution when that functionality wasn't there. System augmentation for AI adds intelligence to get the number right.

Let's take a typical situation.

Demand planning is executed through a system that provides multiple data views, drives down into details, combines information across channels, and allows you to adjust the plan. But suppose the underlying forecast isn't correct or doesn't use the proper demand drivers. Does the demand planner bump it up or reduce it based on their personal knowledge? If the answer is yes (to either) the value is diminished, as people will always have biases. In the next step, sales and marketing teams add their projections to establish a consensus. But is that new number accurate? Probably not. And how quickly can you adjust this plan according to this process? Yearly, biannually, quarterly? When is it too late?

The benefit of augmenting your solutions with AI is maximizing your current investments, increasing innovation speed, and doing so at a lower cost.

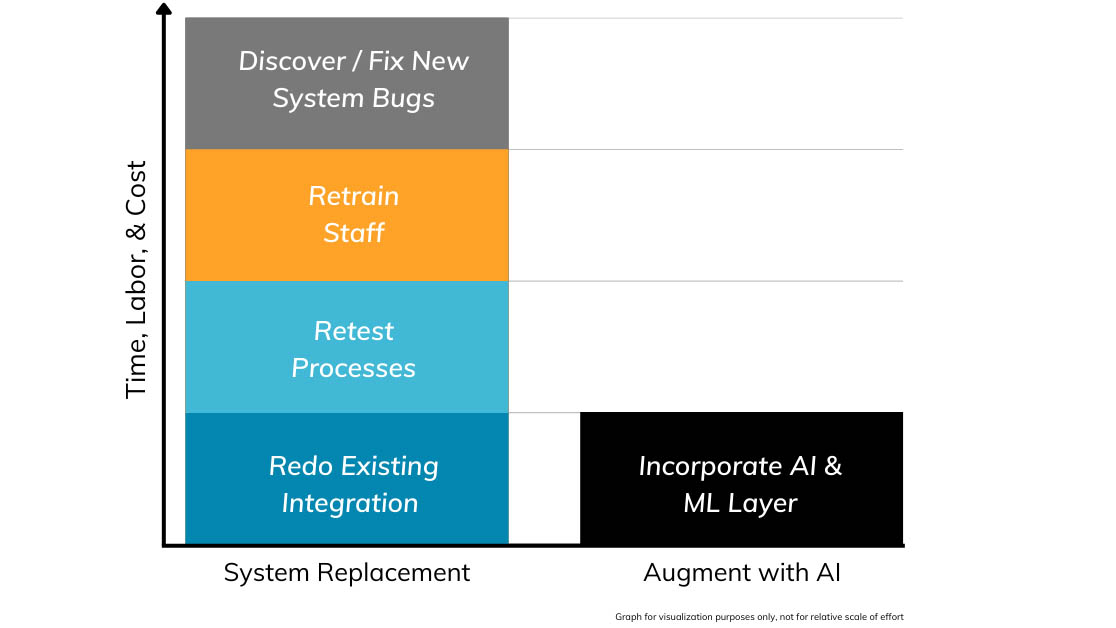

Suppose you have spent millions on a replenishment system that functions well, but you are unsatisfied with the results it is providing you. The problem is that system is already integrated with your warehouse, ordering, and inventory management systems. If you replace the replenishment system, those other interfaces will need to be reworked – for no added benefit, by the way. You're also going to have to retest your processes and retrain your staff. Not to mention all the new issues that will always appear when implementing software. All these refinements require specialists. That means you’re also pulling your people from their day jobs to support the specialists, however long it takes to get to a minimally viable product (MVP) state.

Conversely, if the core issue is that you are struggling to keep up with consumer demand shifts, then the issue may not be the system itself but the forecasting and intelligence behind it. If you could infuse more intelligence into the system (i.e., augment), you can mitigate your largest problem and drive additional value out of your current systems without having to go through any of the more resource-intense refinements I previously described.

Does this mean you never need to replace that system? No. A new replenishment system provides you a fix to your most important issue faster and cheaper than trying most other options. Just make sure you choose one that enables you to keep the intelligence extracted and stored by your previous system while improving the execution portion of demand planning.

This system augmentation approach has already been proven.

Messrs. Simichi-Levi and Timmermans showcase how to spend less and accomplish more in their hbr.org article. In the article, the Head of MIT Data Science Lab & Sr. Managing Director from Accenture state that by leveraging "a consensus forecast with a unified view of demand" as the foundational initiative, they can lower the transformation costs from tens of millions and a 35-year timeframe to a few million and a timeframe of 12-24 months.

The Familiar Tug of Hope

Despite the "whack-a-mole" atmosphere with new issues rising, and others seeming to disappear only to suddenly appear again, we've continued to see improvements through technological advancements and human ingenuity. Like the NFL’s embrace of RFID-derived data, retail and CPG companies welcome data, along with AI, machine learning, and innovative ideas to gain that edge. So, as winter approaches and we get deeper into the football season, many passionate NFL fans, like me, feel that familiar tug of hope for better results and methods, not just on the field but in the workplace, retail stores and other places where our personal and professional lives intersect.

Jasneet Kohli

Jasneet Kohli is head of antuit.ai’s Solution Consulting for Zebra and has more than 15 years of experience generating value for consumer products companies and retailers. He has held various leadership roles across business operations, solution strategy, and customer success. Previously, he served as head of procurement and logistics for Abbott in Singapore and Managing Consultant for IBM.