How Omnichannel is Revolutionizing Retail Inventory Allocation

With online sales increasing, traditional allocation and forecasting methods are costing retailers millions. How many times have you personally had to scramble to find a workaround after realizing inventory is not in the ideal location to fulfill orders routed to your store(s)? I would imagine you don’t want to incur the higher shipping costs or sales losses that result from poor inventory placement any longer. And I bet your bottom line would look a lot better if you didn’t have to constantly markdown inventory sent to lower volume locations just to get it moving off shelves. That’s why I want to talk to you about the far underrated omnichannel allocation capabilities available today thanks to artificial intelligence (AI) algorithms that provide greater visibility into customer demand and inventory movements. This omnichannel allocation technology has already been shown to improve ship completes by 2x higher than traditional allocation and forecasting methods and inventory turns by greater than 250%.

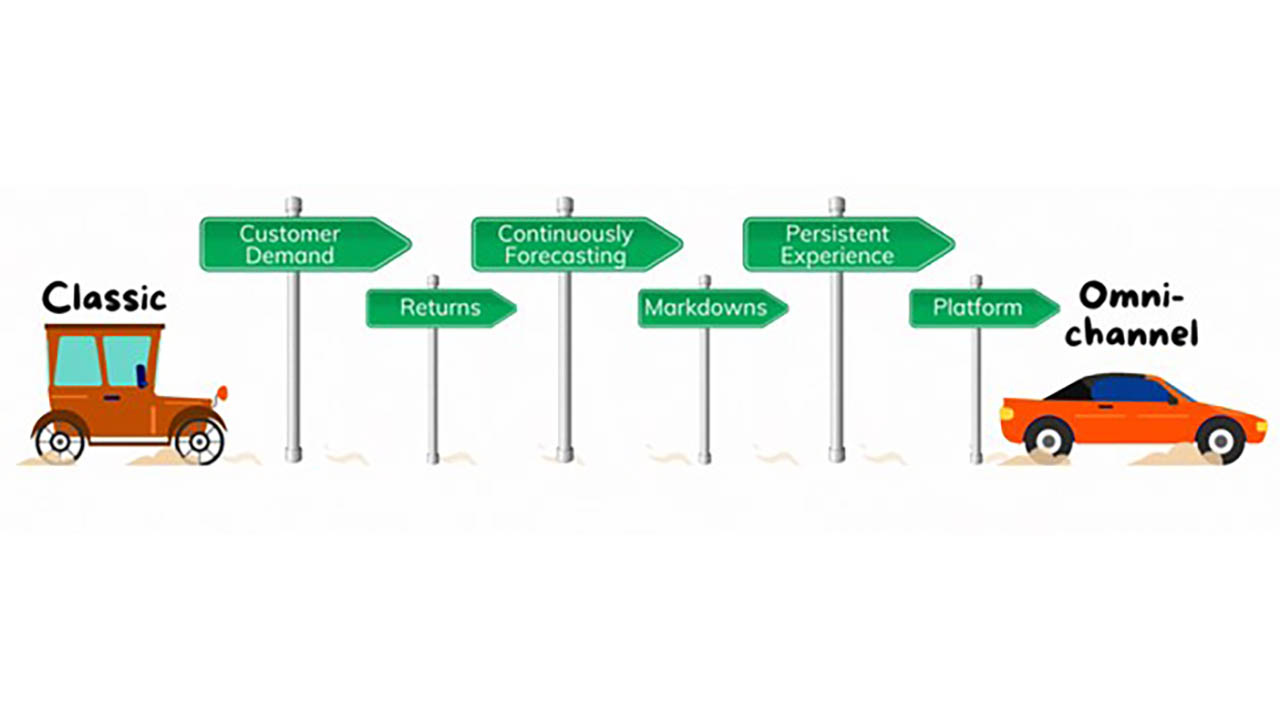

Curious how omnichannel allocation is different than traditional methods?

Let’s talk about six notable points of differentiation:

1. Customer Demand

Every planning decision starts with understanding customer demand. But it’s not enough to know how, where, or why people shop. You must also know how they're influenced, how behavior is changing, how events affect outcomes…everything. Therefore, if you pride yourself on anticipating consumer demand, you must collate and evaluate every data source. This approach is fundamentally different when it comes to omnichannel. Other planning methods either use historical data points to determine next year’s sales, force you to push inventory according to store format, or dictate goods shipments according to a merchandise plan. Traditional methods may also guide you to take store demand and add a fixed number of extra units for in-store pickup or store fulfillment. But that's arbitrary. And simply looking at prior pickup or fulfillment data for the store only tells you what happened, not what should have happened.

That’s why omnichannel allocation software has been designed to instead consider several internal and external data sources and, using machine learning and AI algorithms, predict demand for both the store and online.

One of those external data sources could be customer proximity to stores, which enables you to better align inventory quantity to locations where you know customers have a propensity to buy online and either pickup in store or ship-to-home. You’ll be stocked correctly for both BOPIS fulfillment and more cost and time-efficient deliveries.

2. Returns

Most traditional allocation calculations don't factor in returns. As online shopping has increased, so has the percentage of returns. Worse, most customers who buy online prefer to return in store. Furthermore, the rate of returns as compared to sales tends to increase after a promotion.

Therefore, the rate of merchandise returns must be factored in allocation calculations, and this rate must be accurate at the time of allocation. Perform an allocation directly after a promotion, and there is a higher probability that prior sold merchandise will be returned than an allocation that is done two weeks later. Ignore this, and you will over-allocate.

3. Continuous Forecasting

You know you must continuously forecast throughout each season given the variability in demand that has intensified due to economic factors. Customers’ situations are constantly changing, so any planning algorithms and models need to be fed with up-to-date information about every potential customer behavior – and every potential behavior influence – for this point in time. That pre-season forecast you’ve always relied on is becoming less valuable over time.

4. Markdowns

Demand and inventory at the beginning of the season is different from mid-season, which is different from end-of-season clearance. For that last merchandise push, you must predict how the stock will sell through to avoid over or under-allocating. Typically, this has been done by evaluating the weeks of supply and the current sell-through rate. But this technique is flawed, as it only reflects what happened, not what will happen. If you want to clear the remaining merchandise, you must figure out and make decisions based on expected future demand. The last thing you want to do is to push merchandise to stores that are well beyond their demand peak and then be forced to use massive markdowns to clear the stock. Customers would love that. Your bosses would not.

5. Platform

In omnichannel retail, the customer must remain at the center of all processes. That’s why our omnichannel allocation software is built upon an AI demand intelligence platform that forecasts consumer demand in a way that can be shared with and leveraged by multiple functions in the retail operations decision chain, including planning, pricing, and fulfillment teams. When you leverage an AI software platform such as this to determine demand, you’ll find it easier to work synergistically with everyone else across your retail operation – and even your supply chain – to ensure the right inventory is in the right place at the right time. You won’t have to figure out which of the conflicting calculations or viewpoints is “correct.” Everyone is working from a single – and complete – source of truth.

6. Persistent Experience

Because there are so many “traditional” methods of inventory planning, it’s hard to say which, if any, are best. Every decision may feel like a gamble because demand calculations are based on a narrow set of factors. That’s why AI-powered omnichannel allocation software is necessary if you want to deliver the best experience to your customers in the modern store environment. There is no longer a delineation between brick-and-mortar and online shopping experiences. They are one in the same, and you need to look at demand for all shopping and fulfillment channels in a single pane of glass.

That’s right. You don’t have to scrap everything you know about demand planning to more effectively plan for omnichannel demand – just like you don't have to relearn how to drive every time you get a new car. You simply have to learn how to take advantage of the new features that come with the new car to enjoy a better driving experience – or, in this case, the features of an AI system. At Zebra, we know sophisticated AI can’t weigh down the user. It should be packaged in a familiar process but served through a better experience. This increases user adoption, compliance, and results. So, we have designed an omnichannel allocation platform that makes it possible to account for all potential demand influences – weather, events, economic conditions, crises, personal circumstance changes, life in general. In turn, you have the best chance possible of arriving at the “best” outcome, which is having the right inventory in the right place at the right time so you don’t have to suffer the consequences of high shipping costs, constant inventory transfers, or frequent or steep markdowns.

In fact, we’ve had customers report a 2x increase in ship completes and a 250% improvement in inventory turns using AI-powered omnichannel allocation methods. But this alone isn’t the compelling force to adopt omnichannel allocation. That compelling force is doing what you intuitively know you should be doing. It’s possible to anticipate customer demand when considering all the channels and customer journey. It’s possible to predict how often returns will happen and when. It’s possible to understand the relationship between allocation and future pricing. And we all know it’s possible to demand a great user experience. Technology has created amazing possibilities for customers, and technology can do the same for businesses that embrace it. Will yours?

###

Related Reads:

Jeanne Yeager

With over 20+ years of experience, Jeanne Yeager is an experienced omnichannel retail expert that is passionate about solving complex problems with technology. Her experience in Planning, Allocation, Strategy, and Implementation for Fortune 500 companies and startups has given her many opportunities to view how different companies approach the same goals. Always curious, she has spent much of her career driving innovation and process improvements that allow teams to see the bigger picture rather than spending the majority of their time on redundant non-value-add work.