Use vision systems to address inconsistencies in liquid level detection and achieve precise fill levels for enhanced quality and compliance across industries

Improve precision in fill level inspections

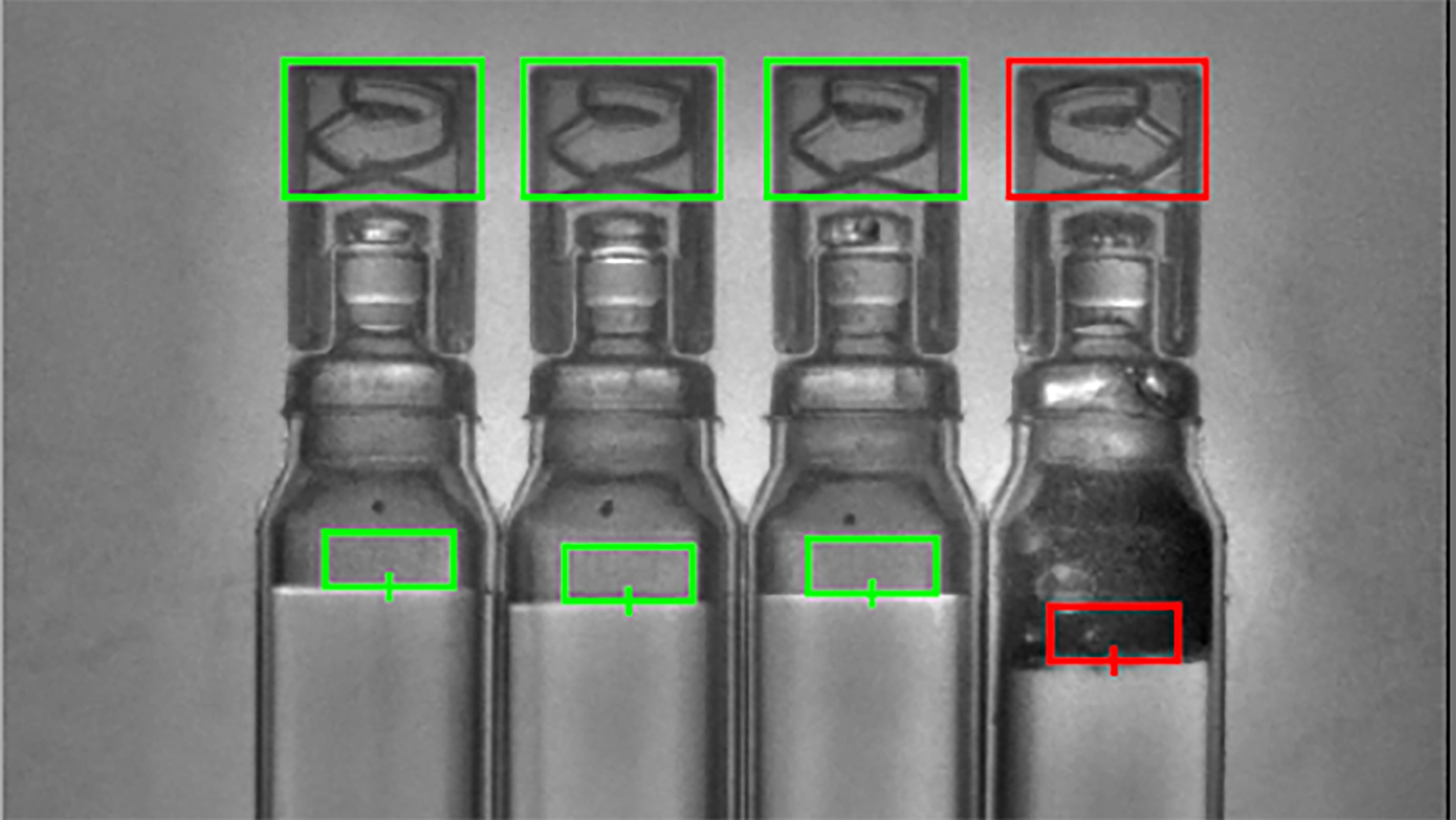

Zebra smart cameras perform high-speed 2D fill level inspections by capturing high-resolution images of containers and analyzing them for correct fill volumes and consistency. Integrated with automated systems, they provide real-time quality control by triggering alerts or rejecting out-of-spec products. Their high-speed accuracy, capable of detecting deviations as small as 10 microns, is crucial for strict pharmaceutical standards in particular. The cameras use advanced optics, lighting, and high-resolution sensors for precise inspections.

Connect inspection to your line and systems

Zebra Aurora Design Assistant provides an intuitive flowchart-based suite of machine vision tools. Design Assist comes with pre-built templates for common 2D and 3D vision applications so teams can develop, deploy, monitor, and adjust inspections quickly. Once developed, applications can easily be ported to multiple devices and systems with the same overall pass/fail logic for consistent quality control across lines and sites. Images of exceptions or rejects can be saved for operator review, shortening investigation, improving error recovery, and reinforcing consumer safety.

Streamline fill level accuracy

Zebra's 3D sensors, such as the AltiZ series, provide precise volumetric measurements regardless of surface color, texture, or transparency, and without interference from low contrast or reflective surfaces. In the Food & Beverage sector, these sensors ensure consistent product fill levels by capturing detailed 3D surface maps, enabling real-time, non-contact quality control to detect and reject improperly filled containers and reduce production waste through automated feedback to filling systems.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.