Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

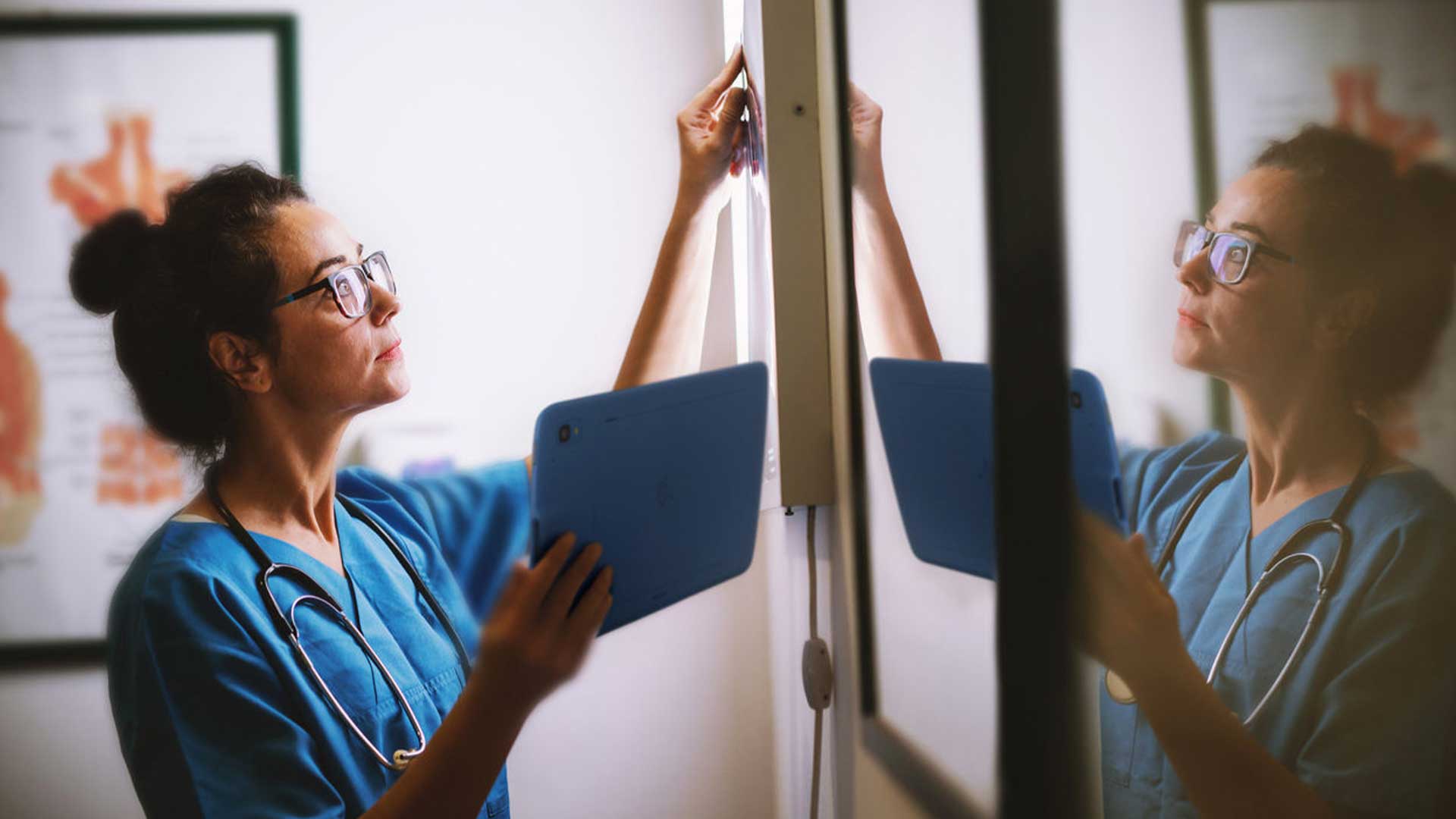

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimise workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customise your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Zebra's location technologies provide real-time tracking for your organisation to better manage and optimise your critical assets and create more efficient workflows.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

Boost productivity with Zebra Frontline AI Enablers: AI vision models, sample apps, and APIs streamline workflows for efficient business processes.

Zebra Frontline AI Blueprints deliver adaptable, real-world AI frameworks that automate manual tasks and drive efficiency in high-pressure frontline operations.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labour costs low, your talent happy and your organisation compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximising IT resources and minimising down time.

Make the most of every stage of your scanning journey from deployment to optimisation. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customisation starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximise productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

“This Has Been a Dream Come True”: Hunt Country Components CEO Howard Hellwinkel Finally Found a Way to Use RFID “Like the Big Companies” in His Upholstered Furniture Manufacturing Operation

Misplacing a piece of furniture might sound difficult, but it’s easier than you think when dealing with thousands of items per day. Just ask the team at Hunt Country Components.

Though they have more than two decades of experience manufacturing upholstered furniture, and a well-oiled production process, CEO Howard Hellwinkel and his daughter, Vice President Heather Hellwinkel Sutermaster, told us that keeping track of pieces at this family-owned business over the years has been much like assembling an office chair without instructions. Since many of the company’s products are packaged in identical cartons, shipping mix-ups have been costing the company time and money for a long time. Too long, really.

But this wasn’t the only pain point starting to nag Howard.

In the last 10 years or so, he started to notice lots of small inefficiencies suddenly causing bigger problems for customers and employees day to day. His team couldn’t provide accurate ship dates to customers, which had become table stakes in the on-demand economy, because no one quite knew the status of work in process across the 110,000 sq. ft. distribution center and factory in Thomasville, NC.

It was also taking way too much effort to pay employees, whose income was determined by how many pieces they sewed, assembled or otherwise contributed to each week. Having to reconcile parts completion records for dozens of employees using hundreds of pieces of paper is tedious and far from perfect.

That’s why Howard started researching RFID.

He knew RFID was helping larger companies track everything from raw materials to work in process and ship orders quite effectively. He wondered if using the technology in this same way made sense for his growing operation, too. He was also curious if it could make payroll easier, perhaps by automatically tracking and reporting completed work into the payroll team.

However, as a smaller business, he didn’t think RFID was financially feasible. He assumed the upfront costs would put it out of reach. So, he continued his research but ultimately relegated RFID to a pipe dream for many years until, one day, he decided to share his vision with his daughter Heather.

Heather had just finished graduate school and decided she wanted to come home to help run the company. When her dad told her about some of the challenges cropping up from production to payroll and how he believed RFID could help quash some of them, she called Kirk Steinhoff, President of ValuTrack Corporation, a Zebra Solutions Partner and trusted technology consultant, to see if he agreed. (She also wanted to know how much it might cost to make her dad’s dream come true.)

As Heather and Howard explained to me in a recent “Story Behind the Success Story” podcast episode, Kirk wasn’t willing to give them advice right away. There were lots of questions the Hunt Country Components team needed to answer before he could answer theirs. It’s never as simple as “RFID solves XYZ problem.” Plus, the “cost” of RFID has too many variables, and it isn’t just about the sticker price. You must consider the total cost of ownership (TCO) alongside the anticipated return on investment (ROI) when deciding what makes sense.

I highly encourage you to hit the play button below and spend 15 minutes listening to what Howard, Heather and Kirk shared with me in that conversation. They explained…

What the solution discovery, design and testing experience was really like (from Howard and Heather’s perspective). [2:12]

Why all parties ultimately agreed RFID was the right technology to help Howard realize his dream (versus a barcode or other automation system). [4:19]

The specific roles that Hunt Country Components employees and outside (ValuTrack and Hal Systems) consultants played in the extensive, weeks-long problem scoping and problem-solving process that played out in the factory and back office (where payroll is processed). [5:45]

How *very* happy customers, employees and the executive team were as soon as the RFID systems came online. (We’re talking within hours on day one!) [10:46]

Some of the creative new ways Hunt Country Components is going to start using its deployed RFID system now that its work in process and payroll functions are automated and working optimally. (And how Howard and team even thought to use RFID in these additional ways to monitor, manage and measure different operational facets.) [14:15]

I’m confident their incredible story will have you wondering what RFID can do for your business – or maybe what more it can do that you have yet to consider. Check it out:

Hunt Country Components: The Story Behind the Success Story

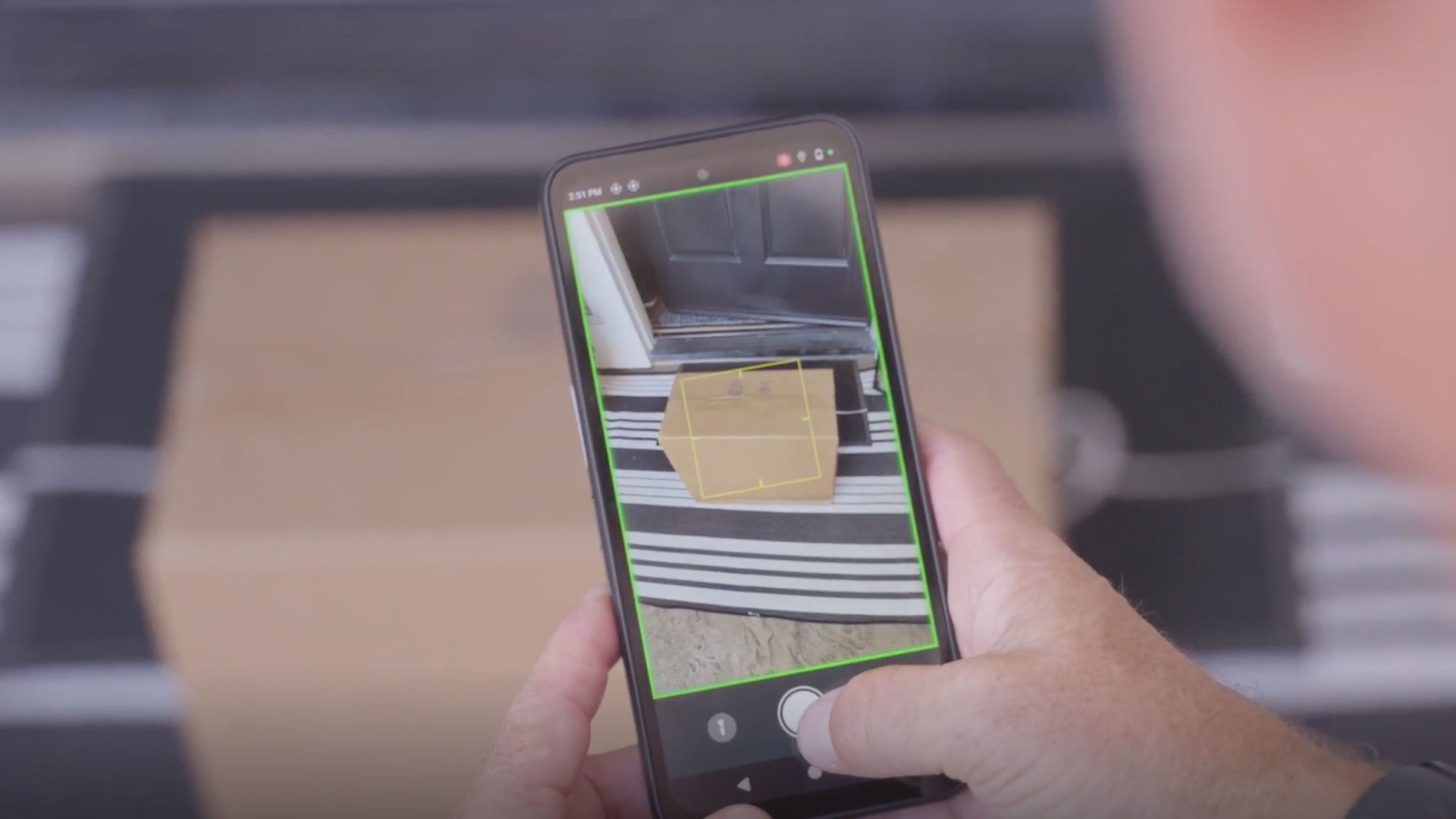

Oh, and it helps if you also watch this 5-minute video showing the RFID system in action in the Hunt Country Components factory and back office:

Bob Grant

Bob is currently the Sr. Director of Advanced Location Technology (ALT) Product Management where he is responsible for the product life cycle of ALT RFID products.

Bob has more than 30 of experience within the AIDC industry and has held many positions from quality to manufacturing and project management in addition to over 15 years in product management.

Previously, he worked in the Print Circuit Board industry as a Chemical Engineer developing high-end resin systems. Bob holds a BE in Chemical Engineering and a Masters in Business, both from Stony Brook University in NY.

Zebra Developer Blog

Zebra Developer BlogZebra Developer Blog

Are you a Zebra Developer? Find more technical discussions on our Developer Portal blog.

Zebra Story Hub

Zebra Story HubZebra Story Hub

Looking for more expert insights? Visit the Zebra Story Hub for more interviews, news, and industry trend analysis.

Search the Blog

Search the BlogSearch the Blog

Use the below link to search all of our blog posts.

Most Recent

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. Note: Some content or images on zebra.com may have been generated in whole or in part by AI. ©2026 Zebra Technologies Corp. and/or its affiliates.