Trying to Reduce Waste and Enable More Efficient Operations in Your Warehouse? Start by Cleaning Up Your Receiving Area

This might feel like a big step, but it’s the best first step given receiving sets the tone for the rest of your warehouse operations. Here are eight things you can do to drive noticeable improvement quite easily.

This post was contributed by Steve Shaheen, CEO, DTG, a Zebra Premier Independent Hardware Vendor (IHV) Partner.

###

Whether you’re an e-commerce or logistics operations manager, you understand that efficient warehouse management is the key to ensuring faster delivery, proper inventory management and cost-effective operations. Yet given the complexity of the warehouse and the many moving parts, I know that warehouse management is no easy task. Success requires an effective plan for inventory management and control, as well as the right tools and technologies to help your team to complete the tasks.

Given that receiving new inventory is the first step in the warehouse operations journey, and problems that occur in this stage can have repercussions across all other parts of your operation, it’s important that you have this process buttoned up. Otherwise, the process of getting goods into and out of the warehouse and into customers’ hands quickly, accurately, and safely will consistently feel like a struggle.

How many times has your team improperly accepted incomplete or damaged shipments, failed to accurately inventory goods as they entered the warehouse, or accidentally stored goods in the wrong locations? Countless, right? And how much time have you and your team wasted trying to fix these mistakes or minimize their bottom-line impact? Too much, I assume.

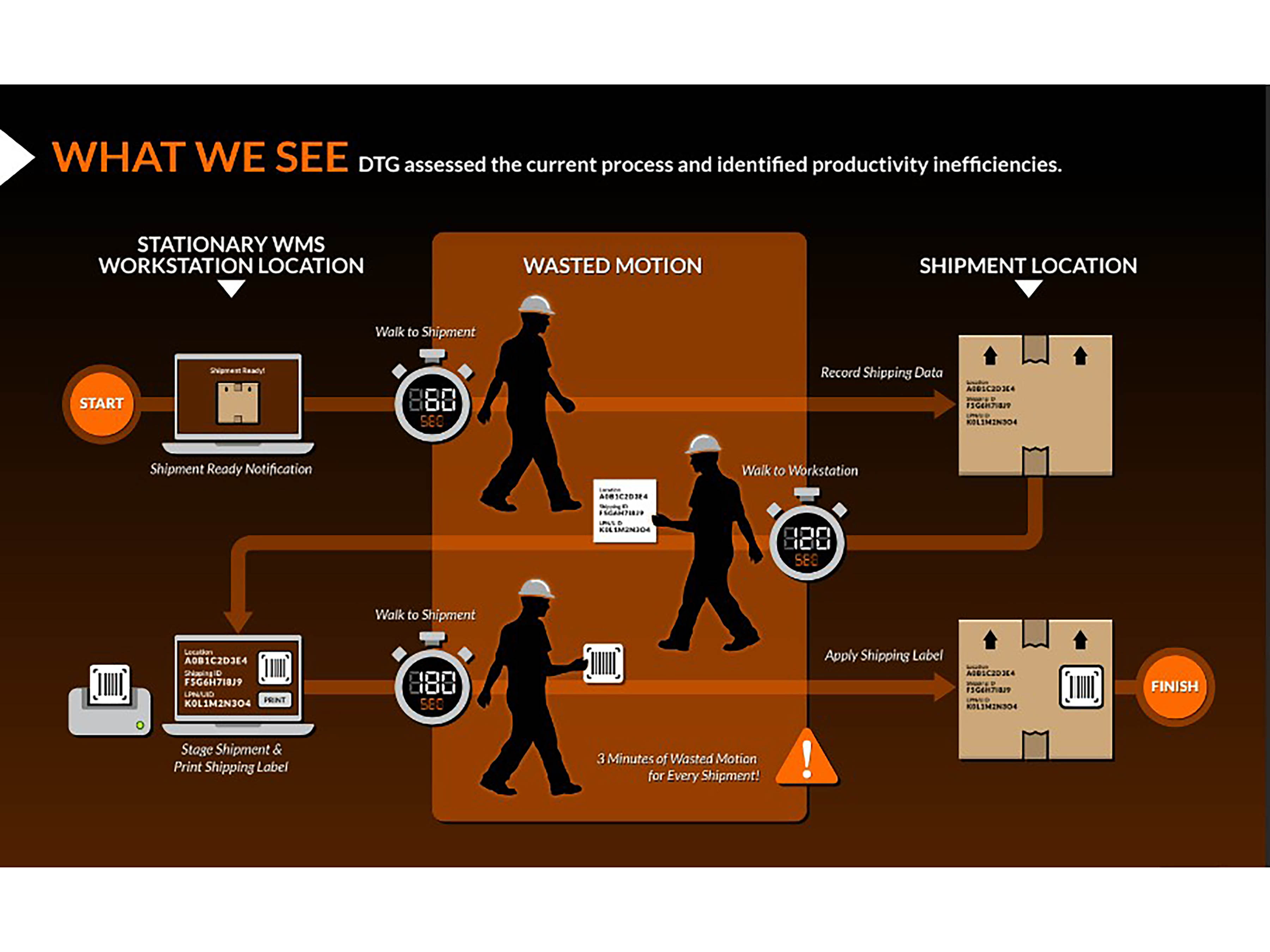

That’s why I always emphasize to warehouse operators that I meet with just how important it is to frequently review the receiving process in the warehouse and see where they can optimize the layout of the receiving area. That’s right. The emphasis needs to be on the physical design first as that has a tremendous influence on the inbound flow. You should be examining processes and the movement of people and goods on a regular cadence to see if there is motion waste. Besides hindering productivity, a layout that requires workers to take additional – unnecessary – steps to unload, unbox, process, and stage inbound orders could cause a safety issue. So, there are many reasons to pay attention to what’s happening here. Just check out these numbers:

Download the full infographic here.

Now, there are many ways to approach this assessment of your receiving area layout and processes, but I have found that doing these eight things will make it easier to create a safe, efficient inbound process that respects what’s working well today and builds upon that to reduce the risk of mistakes:

1. Follow process controls.

It’s the job of the receiving team to unload, inspect, and document new inventory as it enters the warehouse. It’s important they know that. When a new shipment arrives, it should be thoroughly inspected for signs of damage and counted to confirm that the order has been fulfilled. I typically see the inventory clerk assigned to sign off that the order is complete and in good shape. But whoever you have doing it, make sure they know that they must actually inspect the order before signing off. Only once a shipment has been accepted should the receiving team begin entering product information into your warehouse management system (WMS), and someone needs to confirm that each product has an assigned inventory number and a correct label before anyone clears it to be shelved.

2. Focus on the four critical zones.

There should be four critical inbound zones delineated in your warehouse to support the receiving process, and your processes should be arranged around these four zones to ensure a fast, safe, and efficient process flow:

- The receiving zone (or entry point) - This is the dock door where your team meets cargo trucks to unload pallets of new inventory.

- The inventory staging zone - This is the first place that inventory “lands” after being unloaded. The inventory clerk and members of the receiving team should be unloading, inspecting, counting, and accepting shipments of inventory in this area.

- The inventory processing zone - Once inventory in the staging area has been accepted, it should be moved to the inventory processing zone. In this area, your warehouse receiving teams can work to ensure that each new product is assigned an inventory number, entered into your warehouse inventory control system, and properly labeled.

- Put away lane zone - Put-away lanes are typically motorized fixed conveyor belts that carry newly processed inventory from the receiving area to a separate area where teams will sort it and transport it to predetermined storage locations in the warehouse. Although, I am starting to hear about more warehouse operators using autonomous mobile robots (AMRs) in this capacity. You’ll have to figure out what works best for you based on goods volume, labor resources, physical space, etc. There are several people you can consult with to understand your options here and the pros/cons of each.

3. Ensure a robust docking infrastructure.

When designing the receiving dock layout, it’s important to determine the number of dock doors required to handle the expected volume of shipments. Installing enough receiving docks ensures that you can accommodate multiple cargo trucks and unload trucks as quickly as possible to reduce waiting times and prevent bottlenecks in the receiving process. I know this is easier in a greenfield setting, but if it is possible to retrofit your building, it will go a long way in eliminating choke points.

4. Right-size the inventory staging area.

In the same way that enough receiving docks are needed to handle the expected volume of shipments, a large staging area is needed to accommodate pallets of inventory as they are unloaded, inspected, and counted by the receiving team. Consider your current footprint and, if needed, make more room. Again, it may not be easy to execute, but it will be worth it. (Retailers redesign entire stores all the time without closing, moving aisles and inventory in a methodical manner. They might have some tips on what you can do to minimize operational disruptions during the makeover.)

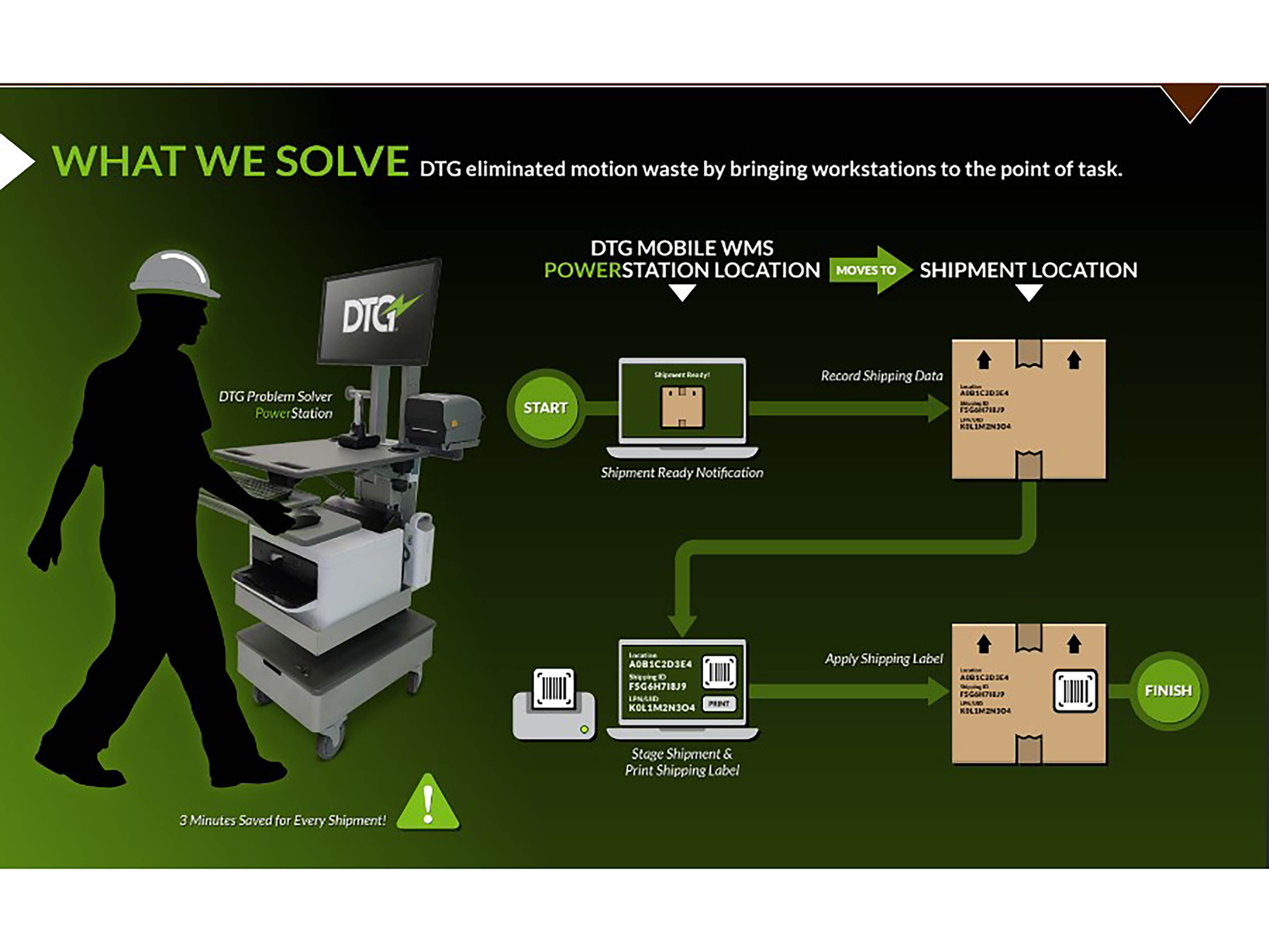

5. Mobilize workers with the tools needed to receive inventory.

There are many different types of technology you can give your team to automate data capture when processing items and entering them into the warehouse inventory control system. In many cases, wearable scanners and mobile computers synced with mobile printers that can be worn on the hip are best, as they keep workers’ hands free to move the items quickly and safely. However, there is sometimes a case to be made for having a battery-powered mobile workstation equipped with a laptop or 2-in-1 tablet and desktop printer for applications where a larger screen can improve efficiency and productivity. So, as you’re looking at the current flow of goods and people, pay attention to what is slowing them down and talk to them about the type of technology that can help them get each task done safely and quickly.

6. Use put-away lanes to route inventory.

I know I’ve said this twice now, but it’s important. You shouldn’t have people running back and forth throughout your warehouse pushing carts or even operating forklifts to get goods closer to their storage shelf location. So, do consider automating this process. It will help save time and reduce errors in the receiving and put-away processes, as the receiving teams can stay in their zone in the inbound area. The put-away teams can stay in their “receiving” zone at the end of the travel lane, and as soon as items flow their way, they can batch and sort the new inventory to make it easier to get items on the shelf quickly. One more thing: Whether you use fixed conveyor belts or AMRs to transfer inventory from the warehouse receiving area to put-away zones, it’s important to create “travel” lanes that don’t impede the movement of other foot, forklift, or AMR traffic.

7. Leave space for heavy equipment traffic.

Just like you’ll need to consider forklifts and foot traffic around your put-away lanes, you’ll also need to enable access for vehicles like pallet jacks and forklifts in the inbound area – by the dock doors and staging area. Travel lanes for these vehicles should be clearly marked and kept clear of inventory/debris to ensure their safe and efficient operation. This is one of the most important considerations when optimizing the receiving area layout!

8. Minimize worker and inventory travel times.

If you want to reduce the travel distance for both workers and inventory, I recommend you make receiving areas wider. Seem counterintuitive? Well, creating a big enough area that you can position inventory staging areas close to receiving docks and staging areas helps minimize the motion waste that slows down the rest of your operation. Just be sure you’re also giving workers the right mobile technology to bring with them to each point of task, whether it’s wearable technology or a mobile workstation, so they don’t have to travel back and forth from a fixed workstation.

If you’d like to talk more about any of these considerations or recommendations, or you’d like to learn more about the way other warehouse operators have set up their receiving areas to remove bottlenecks, you can reach me here.

###