Think Inside the Box: Item-level Monitoring Inside Your Reefer Containers

How can you ensure that perishable items, such as fresh foods, beverages, and pharmaceuticals, carried in refrigerated “reefer” containers, maintain the correct temperatures throughout their journeys? For those who are unfamiliar, a reefer container is a specialized insulated container with an integrated refrigeration unit which is designed to ship temperature-sensitive goods. In this blog post, I explain how using the temperature monitoring systems integrated within reefer containers comes with inherent vulnerabilities. I’ll demonstrate how inexpensive electronic sensors can dramatically improve the accuracy of temperature monitoring inside reefers and help safeguard shipments throughout the supply chain.

Monitoring Reefer Temperatures For Compliance

It’s essential that reefer containers’ temperatures are accurately monitored. This has a dual purpose: both to help handlers maintain the quality and integrity of shipments and to ensure compliance with legislation governing the distribution of products.

For pharmaceuticals, this legislation includes, but is not limited to, the World Health Organization and European Medicines Agency’s Good Distribution Practice (GDP), the U.S. Food and Drug Administration’s Current Good Manufacturing Practice (CGMP), and the U.K.’s Medicines and Healthcare products Regulatory Agency GDP guidelines.

Similarly, for food, cold chain logistics requirements are governed by legislation such as the European Union’s Regulation (EC) No 852/2004, the U.S. CGMP and Food Safety Modernization Act (FSMA), and, in the U.K., The Food Safety and Hygiene (England) Regulations 2013.

What Happens When Reefer Temperature Monitoring Fails?

If the individual products transported within reefer containers aren’t maintained at the correct temperatures throughout their journeys, the impact of failed temperature monitoring can be immense.

Any inkling of a temperature excursion often leads to entire consignments being disposed of. It is a scenario that contributes to some alarming figures with 13% of all food, 35% of all fish, and 12% of all meat being lost or wasted within the global supply chain.

Inherent Consumer Concerns Over Temperature Monitoring

In some ways, stats like this suggest temperature monitoring is generally working. But those failure numbers are way too high in my opinion.

Based on my personal conversations with producers and logistics firms, I also worry the temperature data collected by reefers may not always be accurate. Or, indeed, transparent. And this view is more widely held than many of us may appreciate.

Low Trust in Accurate Temperature Data Capture

Zebra’s Pharmaceutical Supply Chain Vision Study reveals low levels of trust in the data accuracy of temperature monitoring of both containers and individual items during reefer transportation.

Only 40% of pharmaceutical decision-makers say they completely trust the entities within the supply chain to keep medications uncompromised throughout journeys. And only 37% of industry decision-makers and 20% of consumers place complete trust in the food supply chain to ensure safety.

Such sentiment strengthens my view that we need to rethink the way we measure and monitor the temperature of sensitive cargo inside the reefers we all rely so heavily on.

Transparency In Reefer Temperature Monitoring Practices

In theory, most reefer containers monitor and retain temperature data. But, with the average lifespan of containers being 25 years, many run legacy systems. Also, the nature of reefer spaces, and how these are packed, monitored, and managed, creates inherent fallibilities.

These fallibilities often expose vulnerabilities in how companies secure sensitive cargos:

● The shutting the stable door scenario: Ideally, supply chain companies, their operatives, and the producers of goods will have real-time insight into the temperatures of reefer holds. However, while most reefers monitor temperature, many only have the capability to upload their data at depots. Given that any breaches in temperature discovered at this point are historical, cargo items are typically discarded for safety reasons. Moreover, the volume of data collated at depots makes it easy for temperature deviations to be overlooked.

● “Real” reefer data: Even if reefers do have integrated IoT devices that provide real-time visibility, are they reliable?

● The microclimate issue: Reefers are designed to maintain a stable temperature. However, different box and pallet stacking arrangements and densities affect internal airflow to the extent that microclimates can be created. The result is a significant difference in temperature between the front and rear of reefer trailers. The rear, near the door, is usually warmer, for example. All this wouldn’t be an issue if temperatures were monitored at a more granular level. However, reefers usually only have one or two temperature monitors, typically located in the rear of the unit. This “local” reporting creates a false impression of the complete space. Given that fresh food and pharmaceutical items can be susceptible to only a few degrees of temperature deviation, that’s clearly a problem. Also, many reefers generally measure supply and return air temperatures, which provide false information when air flow is poor, and it doesn’t circulate evenly around all products.

● The wrong temperature scenario: If items are loaded at the incorrect temperature, nearby produce can be easily affected by these hot or cold sources. Also, because only one or two sensors are usually in place in reefer holds, spikes in temperature in certain areas can be missed.

● The inadvertent (or otherwise) temperature excursion: Equipment malfunction is a fact of life. While drivers are often able to reset systems, it may not be obvious to them, or discernible in the data, if a prolonged temperature deviation has occurred. Also, while I haven't come across this scenario a lot, I’ve heard of incidents where drivers shut down their trucks at rest stops to save gas. Be mindful, too, that reefer data is often owned and managed by a distribution partner. I know many of our customers would prefer to have a parallel way to collect and share data, so they’re not solely reliant on information provided by others. They want more transparency in their data and access to more immediate insights to ensure the timeliness of information is greatly improved.

Demand for Reliable Reefer Transportation is Rising

Supply chains are becoming more complex and the numbers of products requiring cold chain shipment are rising fast. For example, AI is accelerating advances in biologics, creating new medicines, based on living organisms, which address chronic disorders and enable personalized treatments.

Against this backdrop of complexity and demand, we must take action to address the vulnerabilities that undermine the safety and reliability of reefer transportation.

Empowering Frontline Teams with Better Reefer Monitoring

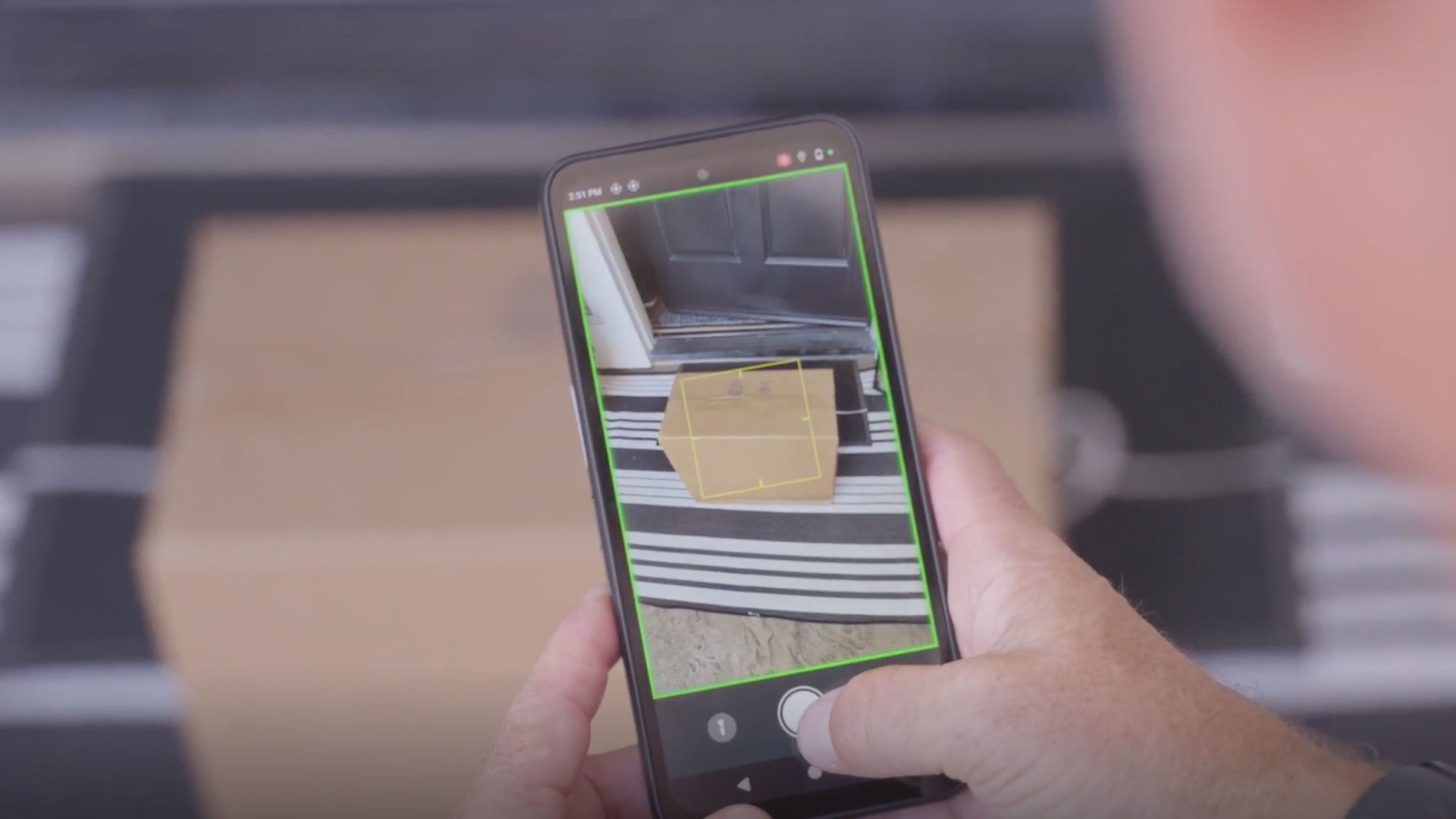

You may be thinking that, in our always-on, IoT, and connected world, there has to be a simpler and better way to collect and share reefer temperature monitoring data. And you’d be right. The ZS300 Electronic Sensor is designed to make life easier for everyone involved in reefer transportation, every day.

Giving Reefer Containers a Digital Voice Makes the Difference

The small, robust, and reliably accurate Zebra ZS300 is an internet of things (IoT) device that gives reefer containers a digital voice. A voice that can stream container location, identity, and temperature data to key stakeholders throughout the supply chain.

Temperatures are monitored across a wide range, from -40°C to +85°C, and -40°F to 185°F, with high accuracy of ±0.3°C (±0.5°F). Easily fixed to virtually any item, the ZS300 Electronic Sensor can record the temperature of pallets, boxes, and individual items. And it’s designed for reusability to increase ROI while also improving sustainability.

Optimized Reporting and Easy Data Access

Once it is installed, you can define the reporting frequency of the ZS300, with the sensor itself natively storing 16,000 records. The data can also be sent via Bluetooth® to your teams’ Android® or iOS mobile devices running the ZSFinder app or you can also offload it at depot endpoints via our compact ZB200 Bridge. From there, the data can be securely shared to the cloud where it can be viewed, downloaded, and published in formats like Excel or PDF via a PC dashboard for audit and analytical purposes.

Simple cloud-based tools accelerate custom app development. You can seamlessly create audit reports and connect the data with your supply chain systems via versatile application programming interfaces (APIs). Alarms alert drivers and remote teams to any temperature deviations, with apps providing actionable intelligence and next-step guidance. This helps them understand when an issue is bubbling away and what they need to do to help protect items in their care.

Insights that Improve All-Round Protection

Zebra ZS300 Electronic Sensors are simple, precise, and effective. Installing them is an easy way to deliver insights that improve all-round protection.

Whether you run your own vehicle fleet, or use third-party logistics (3PL) providers, the sensors can be installed in all reefers to provide the granular insights often missing from current setups. What’s more, with their low cost and ease of use, you could also justifiably request that any third-party distributors use ZS300s in their shipments.

Critical Benefits and a Compelling Business Case

While integrated reefer monitoring is essential, redundant pallet or even package-level monitoring, as enabled by the ZS300, offers critical benefits to complement reefer systems. These benefits include precise localized tracking, data continuity during reefer failures, granular insights for sensitive goods, and improved accountability.

The improved insights also support regulatory compliance, build customer trust, and mitigate risk. By giving businesses control over reefer temperature monitoring data, the ZS300 makes a compelling case for organizations focused on preserving the quality and integrity of their products throughout the supply chain.

Good For Your Teams, Your Business, and the Environment

The ZS300 also helps your teams minimize the environmental impact of their operations by giving them the confidence to make data-led decisions that reduce the risk of spoilage and unnecessary resource consumption.

The sustainable credentials of this game-changing device extend further, too because the sensors are sold in multipacks using minimal biodegradable packaging. And, with Zebra’s no-cost recycling program, you simply return the devices to us at the end of life.

Our Commitment Helps Companies Work Better Every Day

As you can see, there are many practical reasons behind the need for better reefer temperature monitoring. And these typical scenarios are backed by key research findings.

At Zebra, we don’t just sell solutions. We partner with businesses to solve their toughest challenges. Our goal is simple: connect frontline teams, provide visibility into every aspect of a business and its assets, and drive intelligent operations that make work easier every day.

We’re deeply committed to supporting Transportation & Logistics (T&L) leaders by developing innovative solutions that make a difference. We’re dedicated to delivering actionable insights and the decision-making data they need to protect and optimize their operations at every step of the supply chain; locally, regionally and at a global level.

Zebra’s cost-effective IoT solution gives reefers and individual items a digital voice to provide granular, near real-time data at any level. It equips teams with precise data and actionable intelligence to better manage items in their or others’ care with the added confidence that you can seamlessly capture continuous, auditable insights to validate compliance, from origin through delivery.

![[Category, Subcat or Product] Representational Image 16:9](/content/dam/zebra_dam/global/zcom-web-production/web-production-photography/newsroom/2026-images/photography-web-newsroom-featured-03-16x9-en-us-013026.jpg.imgo.jpg)