Ecopolplast Powers Digital Product Passports and Hits 98% On-Time Delivery with Zebra RFID Technology

Ecopolplast's manual, paper-based warehouse tracking was slow and error-prone. Staff were tracking hundreds of big bags across multiple warehouse levels with paper and clipboards—leading to lost time, gaps in traceability, and creating room for costly errors.

Zebra Success Story: Ecopolplast

Overview: Manufacturing Challenge

Ecopolplast wanted to implement a real-time tracking system to eliminate errors and provide the complete material traceability required to launch its innovative Digital Product Passports.

Benefits / Outcomes

- Successfully rolled out Digital Product Passports (DPPs)

- Inventory accuracy up by 15% within 1 month

- Cycle count time cut by 5X

- 10% improvement in on-time delivery rate

- Overall throughput boosted by roughly 20%

- Attracted new customers by providing CO2 emissions traceability through DPP

About Ecopolplast

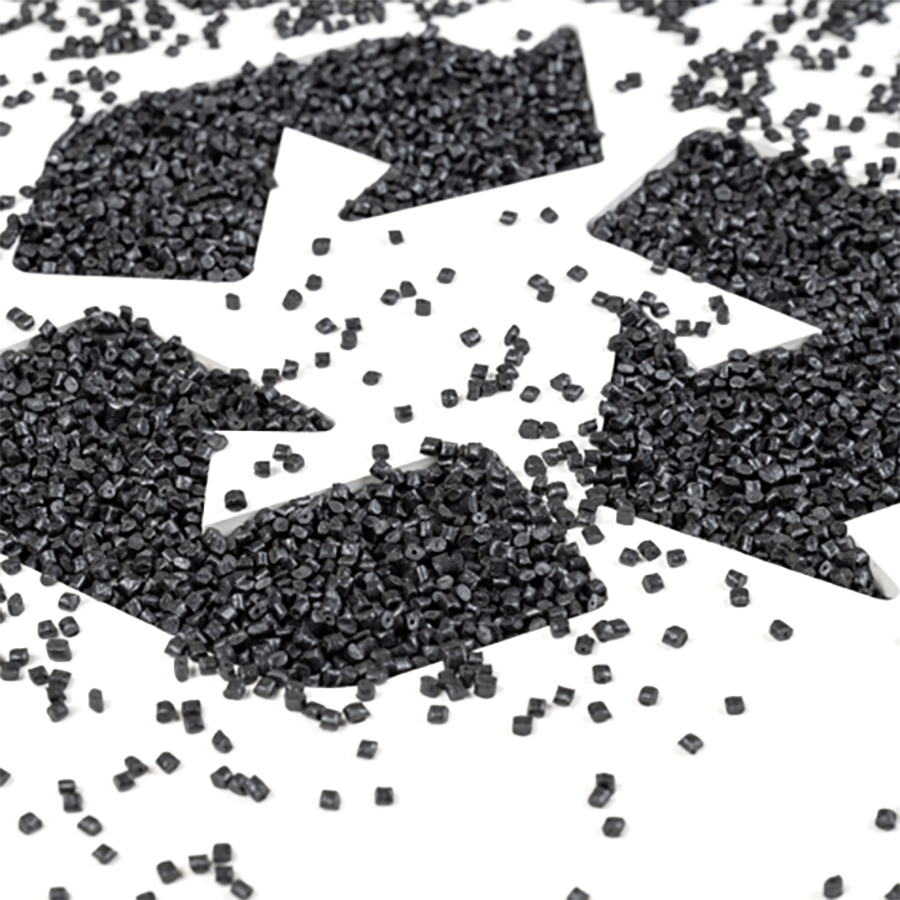

Every year, the world produces over an estimated 400 million tonnes of plastic waste according to the UN, and discards about four billion tyres into landfills according to WBCSD. In Poland, one company is turning that waste into opportunity.

Founded in 2018, Ecopolplast has developed Ecoplastomer®, a thermoplastic made entirely from recycled plastics and post-consumer rubber and gives manufacturers who use it a practical way to comply with tightening regulations. “Many of our customers are required to lower CO₂ emissions or increase the use of recycled materials in their products. That’s where we come in, because our material also reduces CO₂ emissions by up to 70%,” explains Katarzyna Pokwicka, Founder and Chief Executive Officer at Ecopolplast.

The Challenge

Ecopolplast’s warehouse once operated entirely on paper and memory. Materials were stored across multiple levels, tracked with clipboards, and counted by hand. Finding a single bag often meant several forklift trips. “The warehouse used to be a major bottleneck—a source of daily frustration,” says Agnieszka Ryfa, the Chief Operating Officer at Ecopolplast.

The manual system also left significant room for error. As Ecopolplast expanded from a few products to managing dozens of variations within each line, the likelihood of mixing up materials increased. “The problem came to a head when a major client received the wrong variation and walked away, even after the company offered to replace it. We needed to ensure such a mistake would never happen again,” Ryfa says.

At the same time, Ecopolplast was cooperating with Circulens to implement Digital Product Passports (DPPs)—a new EU initiative requiring full traceability of materials throughout a product’s lifecycle. “Right now, everything is marketed as ‘green’ or ‘sustainable,’ but often the reality doesn’t match the claims. With the DPP, you have to report every raw material used in your product and show where it comes from,” explains Pokwicka. To make that level of transparency possible, the company needed a system capable of tracking every movement and material in real time.

Ecopolplast sought out support from Onyximity, who suggested implementing a radio frequency identification (RFID) system, utilising readers and antennas to locate products across the warehouse. “Sustainability and long life are part of who we are, and so we were looking for equipment that would be reliable, durable, and easy to use,” explains Pokwicka. “Onyximity directly recommended Zebra Technologies.”

The digital product passport adds a powerful layer of credibility and proof behind carbon footprint emissions of each product. It’s a game-changer, and we wouldn’t have been able to implement it without fully automated processes that Zebra’s RFID technology provides.

The Solution

Ecopolplast began by printing RFID tags using Zebra ZT411 printers and attaching them to every big bag in its warehouse. “Zebra high-performance printers produce custom labels and reports on demand, ensuring every tag is printed with crystal clear precision and an embedded RFID chip,” says Rifa. “These tags are built to withstand the dust, humidity, and rough handling of our factory environment.” Next, the company installed Zebra’s FX9600 fixed RFID readers, with Zebra AN480 antennas mounted at key points such as receiving docks, storage aisles and shipping areas. Each tagged item is now automatically logged in as it moves through the facility, with real-time location data fed into Ecopolplast’s inventory system.

Alongside the fixed readers, staff use Zebra’s TC26 mobile computers—handheld devices that let them scan tags, record cycle counts, check stock levels and carry out quality checks digitally instead of on paper.

With guidance from Onyximity, Ecopolplast rolled out the system in three phases—planning, installing, and fine-tuning as new needs emerged. “Whenever we needed support, help was there. One call to Onyximity brought immediate answers. Having Onyximity as a partner was crucial to our success,” shares Ryfa. Training was also straightforward. Management learned the system first, then coached staff one by one—addressing concerns and showing easier ways to work. Overall, adoption was smooth and quick.

The Zebra Difference: Outcome and Benefits

With its RFID system up and running, Ecopolplast was also able to roll out Digital Product Passports (DPPs) in collaboration with Circulens, the ESG Institute, and Logifact Systems, to become one of the first companies in the world to do so. Linked to each bag through Zebra’s RFID hardware and integrated with Circulens’ AI-powered platform, the passports act as a living record of every product’s journey: where it was made, what it’s made of, and how it can be reused or recycled.

Now that it is easier to analyse and demonstrate the origin and traceability of materials used in each product through the DPPs, Ecopolplast feels it has gained a competitive edge. “When we meet potential clients, we always mention that we already have digital product passports, and they’re amazed. You can see it on their faces—they want to do business with us because they see we’re not greenwashing,” says Ryfa. Pokwicka recalls a telling example: “At a defence industry exhibition, as soon as I mentioned DPP, the conversation changed immediately. Even though it’s not mandatory in Europe yet, for us as a startup, the digital product passport adds a powerful layer of credibility and proof behind carbon footprint emissions of each product. It’s a game-changer, and we wouldn’t have been able to implement it without fully automated processes that Zebra’s RFID technology provides.”

After fully switching to Zebra’s RFID system and the FX9600 readers, Ecopolplast gained full visibility over its warehouse operations. “There’s no more guesswork. Everything just flows,” says Ryfa.

This visibility leaves little room for mistakes. “Within the first month, we saw a 15% increase in inventory accuracy,” says Ryfa. “Real-time tracking has helped us avoid production shutdowns and delivery errors.”

Greater transparency has also made the team faster and more efficient. “Our on-time delivery rate climbed to 98%—a 10% improvement over the previous year,” notes Ryfa. Because products are now scanned automatically, employees no longer have to pull down bags one by one with a forklift to check their labels—a major advantage during audits or when tracking down missing stock. “Cycle counts that used to take three days are now done in about an hour and a half,” Ryfa adds. “Our workers spend less time hunting for items and more time on value-added tasks, boosting overall throughput by roughly 20%.”

As Ecopolplast prepares to expand into larger plants, it plans to keep using Zebra’s durable devices. “Financially, the return on investment is clear. Today, our warehouse is ultra-functional and a model of modern efficiency,” notes Ryfa. “The implementation didn’t just fix our problems—it pushed us forward, proving that the right technology can turn challenges into triumphs. Most importantly, however, it gave us the necessary base for DPP implementation.”