Unify part verification, vision-guided mounting, and traceability to keep wheel assembly precise, safe, and on schedule

Verify parts with fixed industrial scanning

Zebra fixed industrial scanners read 1D and 2D codes on tires, wheels, and totes to confirm the correct part against the bill of materials. The scan result ties the serial to the vehicle ID for traceability purposes. Scanned data flows to the Manufacturing Execution System (MES) or Enterprise Resource Planning (ERP) system for logging against a master record for traceability, compliance reporting, and downstream service history.

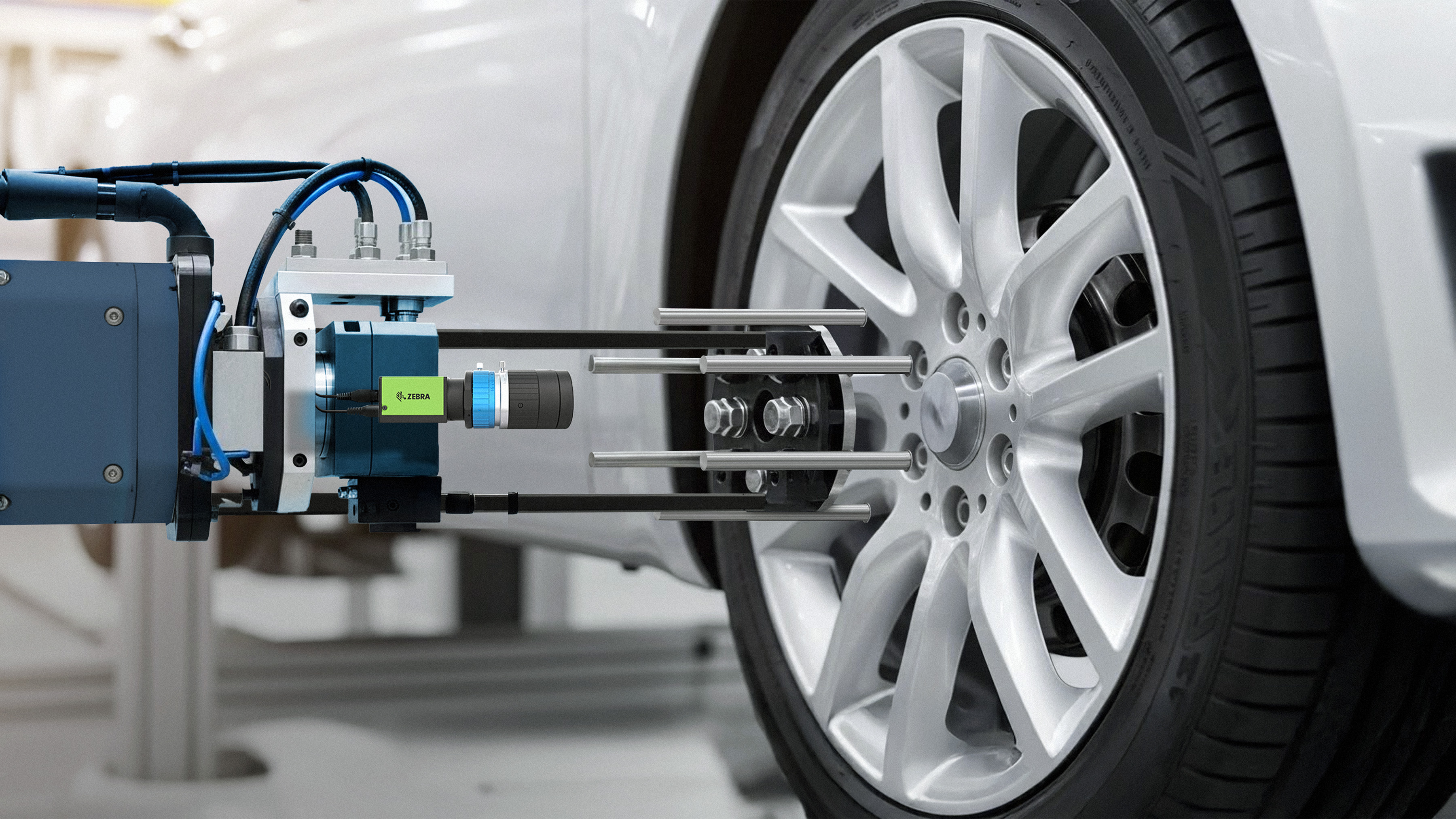

Mount wheels with vision-guided robotics

CV60 industrial cameras, paired with machine vision systems, guide robots to pick, align, and mount the wheels to a vehicle with high repeatable accuracy. The cell uses high-speed imaging to locate studs, measure runout, and confirm wheel orientation before insertion, which prevents cross-threading. After mounting, the vision system checks fastener presence and reads tool status indicators to confirm tightening. The system signals the programmable logic controller (PLC) for go/no-go and logs results to the Manufacturing Execution System (MES).

Add presence checks and final assurance

Aurora Design Assistant software runs final presence and absence checks to verify correct wheel and tire assembly while keeping lines moving. The system can verify part part numbers used in the assembly, ensure that the trunk lid is open before a robot loads the spare tire and can validate that all required clips and caps are installed. Results feed the overall pass/fail logic, which creates a complete traceability record for each vehicle and shortens root-cause analysis during audits.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.