Bring preassembly accuracy to power train lines with 2D vision for part verification and 3D bead measurement for sealing quality

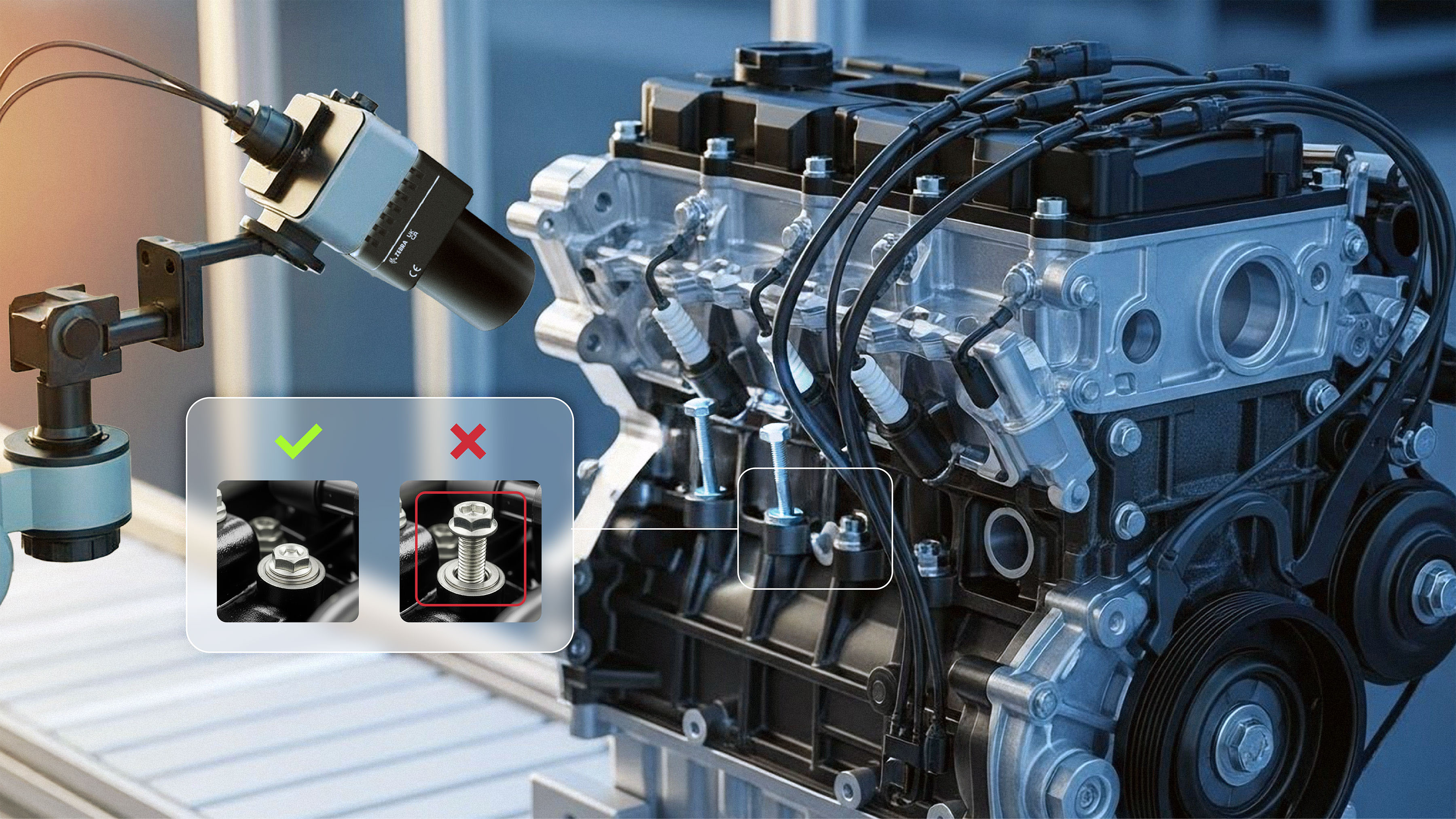

Automate 2D inspections on the line

Zebra Iris GTX smart cameras automatically confirm 2D features are correctly formed and defect-free at the point of build. They measure gear and shaft positions in transmission bodies, verify fastener presence, and check gear teeth for nicks and burrs. Measurement tools allow users to set desired tolerances for critical dimensions, whilst pattern matching and optical character recognition (OCR) tools enable the setup of presence and absence checks for critical features and identifiers. Once deployed, the system triggers pass/fail outputs to the line, preventing bad parts from advancing and standardizing quality across shifts and model variants.

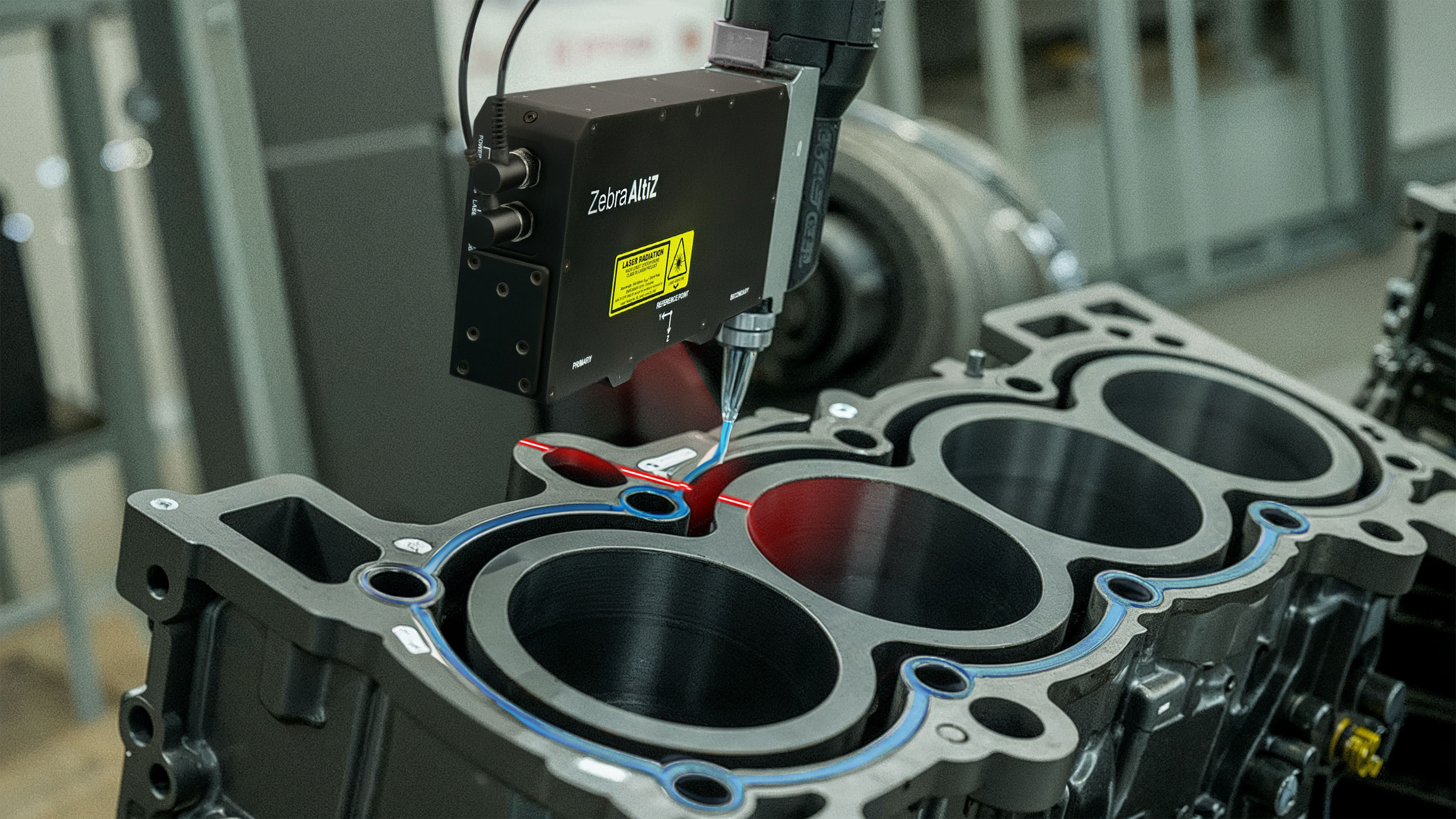

Measure beads and catalytic elements in 3D

Zebra AltiZ 3D profile sensors mounted on robots or fixed stations measure sealant and adhesive beads to gaskets and other powertrain components in motion, capturing width, height, and profile even on low‑contrast surfaces. Zebra Aurora Design Assistant software defines bead paths, compares profiles to tolerances, and associates results to each workpiece ID for traceability. When a skip or thin area appears, the system flags the cell for adjustment or stops the station with clear operator guidance, protecting downstream assembly and reducing rework and leaks.

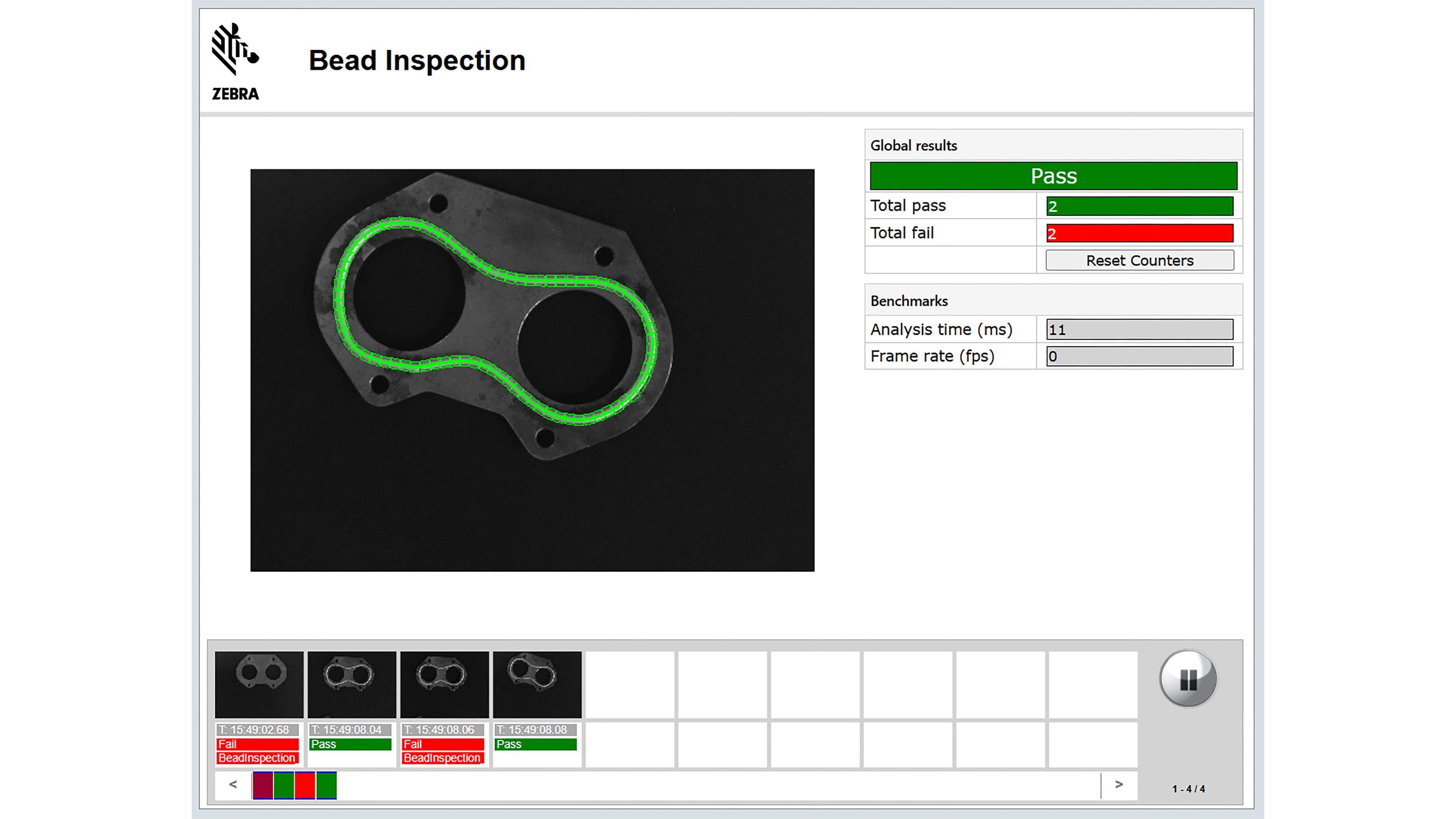

Guide robots and inspect beads with 3D software

Aurora Design Assistant machine vision software provides a comprehensive portfolio of vision tools and premade templates to accelerate automotive inspection application development. The platform connects to major robot and PLC ecosystems over industrial protocols, unifying guidance, inspection, and data logging configuration. The software also provides a single integrated and hardware-agnostic environment for the development of inspections across both 2D and 3D vision, which means it will work for both Zebra and third-party hardware.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.