Is It Really Possible for Consumer Packaged Goods (CPG) Companies and Retailers to Predict – and Plan for – Future Demand?

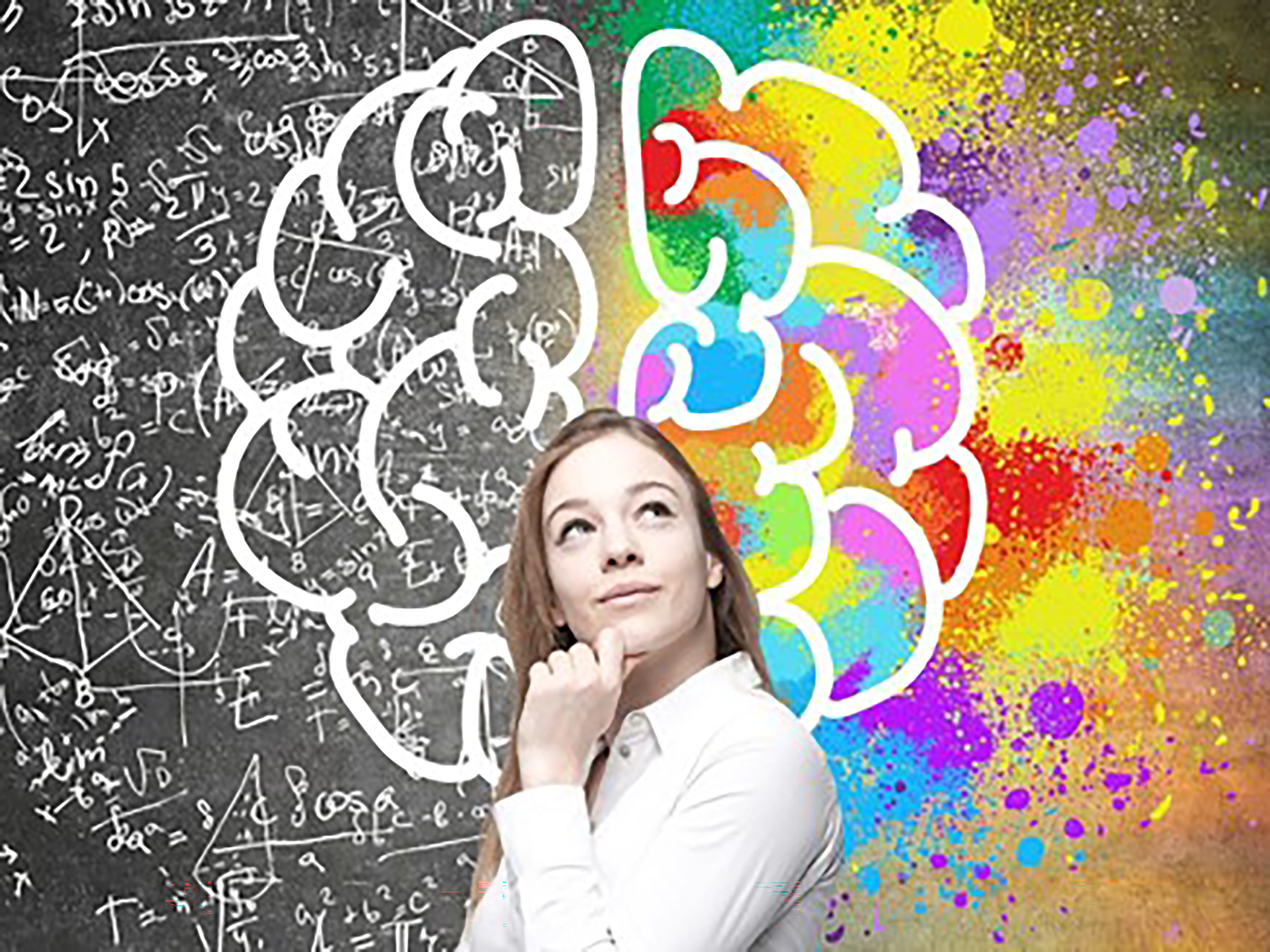

There’s both an art and a science to forecasting, especially when trying to achieve the “right” level of inventory. That’s why you need both people and AIs contributing to your fact-gathering and decision-making.

In a world where precision and preparedness are paramount, forecasting stands as the heartbeat of decision-making. From predicting the metrics of a patient in an intensive care unit at a hospital to predicting the undulating rhythms of the economy on a local or global scale, forecasting is the underlying science that enables us to see and plan the future. It’s a technique based on statistical and machine learning algorithms that learns the patterns and relations from past and present data to give us an idea of what might happen next. How good a forecast will be will depend on both the quality of the data and algorithms used. However, the premise is that we can set future expectations based on historical and current events and behaviors.

This takes me back to my original question: What is forecasting?

We understand that we should forecast, and we have a general idea about how to arrive at a forecast, but why should we commit so much time to this exercise? It will never definitively reveal the future. It’s still a caveated expectation. So, why forecast? What does a forecast do for us individually or collectively as people? Why is it so important that we work diligently to get our forecasts “right”? Why is there such a negative impact when we don’t?

Here’s my take (though I’d love to hear yours, too):

Forecasting is at the epicenter of the most critical outcomes that touch the essence of human existence – outcomes derived from a series of decisions made by those in retail, manufacturing, healthcare, and government alongside their supply chain partners. Therefore, forecasting is not just a tool but a guiding light, illuminating the path from uncertainty to clarity, from chaos to control.

For retailers and consumer packaged goods (CPG) companies, it has also become their backbone. That’s because forecasting is the linchpin that holds together the complex machinery of supply and demand.

It’s a meticulous orchestration of numbers and predictions, where a single misstep can lead to cascading effects – from stockpiles of unsold goods to the echo of empty shelves.

If you’re a retailer or consumer goods manufacturer, I know you don't just care about forecasting; you live by it. It dictates your strategies, informs your decisions, and ultimately shapes your success in a landscape where a day's delay, a misjudged trend, or an unanticipated demand can mean the difference between soaring profits and staggering losses.

And I’m sure you’ve come to realize that forecasting in retail and CPG is not a siloed function; it's a collaborative effort involving multiple stakeholders. From the procurement team assessing raw material needs to the marketing department planning promotional campaigns, accurate forecasts help ensure that all departments’ efforts are synchronized and strategically aligned. This alignment is crucial in an era where consumers expect personalized experiences and rapid fulfillment.

That’s because demand planning, the process of forecasting future customer demand, hinges critically on accurate forecasting, serving as its foundation.

Why Demand Planning Can’t Happen without Accurate Forecasting – and How to Get an Accurate Forecast

At its core, forecasting is the key ingredient in demand planning, acting as the predictive mechanism that feeds into the broader demand planning process and serving as an integral component of effective supply chain management.

It is through forecasting that demand planners can anticipate and adjust for shifts in behavior, whether that’s through inventory level optimization or labor allocation. This rightsizing helps both manufacturers and retailers reduce costs and increase profitability, as they can avoid overstocks (and waste) as well as shortages (and missed opportunities). Additionally, accurate demand forecasting contributes to environmental sustainability by preventing overproduction, which helps reduce waste and conserve limited resources.

In fact, much like other forecasting efforts, the demand planning process starts with the collection and analysis of historical data. The main difference with demand planning is that forecasts are based upon historical sales, promotion data, event data, and any other relevant information that can impact demand.

Once key data is aggregated, it’s then fed into sophisticated forecasting models, which often utilize advanced statistical methods and machine learning, a type of artificial intelligence (AI), to identify patterns and correlations in the data. It’s these patterns and correlations that enable you to predict future demand with a high degree of accuracy. The forecasted demand then forms the basis for various strategic and operational decisions, such as production scheduling, inventory management, and procurement planning.

Challenges of Accurate Forecasting (and Demand Planning) in Retail and CPG

I probably don’t have to tell you that the dynamic nature of consumer behavior and market trends can make it feel impossible to get an accurate forecast. I’m also aware of how difficult demand planning has become since the start of the pandemic. You just never know what you don’t know.

However, there are some consistencies that we can account for no matter what, one of them being demand inconsistencies.

I have no doubt that one of the primary hurdles you’re facing right now is ever-shifting consumer preference which can change rapidly due to various factors such as emerging cultural trends, socio-economic shifts, and global conflicts. Knowing this volatility makes it difficult for you to predict future demand with precision given that past data might not always be a reliable indicator of future patterns, you need to find ways to account for the consistent inconsistencies. That’s where advanced analytical and AI techniques can prove quite effective.

For example, by leveraging advanced AI and machine learning algorithms, you can dynamically adjust your forecasting models to account for real-time data and emerging trends, enhancing the accuracy of future demand predictions. These technologies enable the identification of subtle patterns and correlations within vast datasets that human analysts might overlook, allowing for the anticipation of shifts in consumer behavior before they become apparent. By incorporating AI and machine learning, you can both navigate and capitalize on the fluid landscape of consumer preferences, ensuring you remain competitive in a rapidly evolving market.

I know another significant challenge you’re probably facing is the complexity of managing a vast array of products, each with its own lifecycle and demand curve. You may be handling thousands of stock-keeping units (SKUs) and forecasting for each one requires a deep understanding of its unique demand pattern. Seasonality of course adds another layer of complexity, with certain products seeing spikes in demand during specific times of the year. (Though even that demand level can fluctuate from year to year depending on what’s happening in the world, leaving you rushing to either restock shelves or deal with dead inventory.)

That’s why a highly nuanced approach to forecasting is necessary.

Now, before you worry that such an approach is too resource-intensive and difficult to scale, let me note that there are now advanced AI algorithms capable of scaling to large volumes of data by leveraging graphics processing units (GPUs) and/or distributed computing. GPUs have revolutionized the field of AI and machine learning by providing the computational power necessary to process and analyze large datasets at speeds significantly faster than traditional central processing units (CPUs). This capability allows for the training of complex AI models on extensive data sets in a fraction of the time, making scalable, real-time analysis not just feasible but also cost-effective.

While leveraging GPUs represents one method for scaling model training, distributed processing offers an alternative approach. This strategy involves utilizing a network of machines, rather than a single unit, to train models. By distributing tasks across several machines, distributed computing significantly improves the system's capacity to simultaneously manage and analyze large volumes of data.

In Other Words

The increasing expectation for personalized consumer experiences and rapid fulfillment has raised the stakes for accurate forecasting, no matter where you are in the supply chain or what you’re ultimately delivering in your supply chain (i.e., groceries, apparel, pharmaceuticals, etc.). Consumers today expect every product technically “on the market” to be available when, where, and how they want them, leading to the need for more localized and exhaustive forecasting. This requires you to have a sophisticated and world-class data infrastructure capable of processing and analyzing large volumes of data at a granular level. It may take several months and an engineering skillset to set up a robust and reliable data infrastructure to enable machine learning forecasting. However, such investment and effort have become necessary as the need for agility and flexibility in forecasting processes is paramount.

You are always going to be challenged by changes in regulatory environments and competition. And no matter how hard you try to mitigate supply chain disruptions, there’s always a risk of a storm or other natural disaster that can delay or stop deliveries right at a time when demand spikes.

So, whether you’re a CPG or retailer (or otherwise responsible for goods production or distribution/sale), let’s talk about how we can get you set up with the AI-powered solutions you need to anticipate and adjust for the future. I realize the endeavor may be complex, but you won’t have to take it on alone. Plus, once you’ve got your systems set up and your algorithms well trained, your demand planners – your decision makers – will be better informed. They’ll have forecasts that more accurately account for evolving consumer behavior and expectations, and that can make a real difference when your goal is to better serve your customers (which better serves your bottom line).

Let me and my colleagues know when you want to talk.

###