Why Your “Loss Prevention” Efforts Aren’t Working

Do you know exactly when, where and why they’re happening? If not, it will be hard to figure out how to prevent them, fix inventory distortion, and eliminate friction for your loyal shoppers. So, let’s talk about loss detection.

Editor's Note: This post first published January 2024. It was updated August 2024.

###

Ever since retailers started reporting record losses on quarterly earnings calls in early 2023, my phone has been ringing off the hook. Everyone from asset protection professionals to reporters to my next-door neighbors want to know where things are going wrong. How is so much inventory walking out the door in these stores? Why aren’t thieves being stopped? Some are literally showing us how they’re stealing on social media. (People clearly aren’t scared of being “caught on camera” anymore.)

So, why in the world is it so hard to stop them?

In my experience, loss prevention efforts fail because business leaders are too focused on loss prevention and not committing enough resources to loss detection.

I also feel that too many business leaders don’t think there’s a way to stop the losses because they don’t want to “spy” on employees or customers, or they prefer to avoid falsely accusing someone when they don’t have hard evidence proving someone’s role in known losses. They also underestimate the losses they’re experiencing each day, misjudge the true source of losses, or simply accept the losses as part of doing business.

First off, losses are preventable if you understand…

What is going missing (and why).

What might go missing (and why).

How items are disappearing. (The actual scheme, whether accidental or intentional.)

Where items are disappearing. (Garbage chute? point of sale (POS) bypass? The loading dock? Employees’ bags?)

What else, beyond theft, is causing inventory distortion. (Are items just misplaced and, therefore, seemingly “gone”? Did someone confirm receipt of a certain quantity without actually confirming that the quantity was on the pallet or in the bin? Was there damaged product that was tossed per protocol but not denoted in the system? Incorrect SKU inputs at the point of sale?)

How financial losses occur even when the shelf stock matches the inventory system. (Admin errors? Incorrect markdowns at the register or price labels? Stacked coupons that weren’t allowed but an associate/manager applied to keep a customer happy?)

However, you will never understand these things if you are not paying attention to – and documenting with hard data – what people are doing. When items start disappearing from retail stores, hotel rooms, warehouse shelves, trailers, kitchens, etc. or you just can’t seem to balance the books, you need to study the actions taken by the people who work for you, buy from you, or sell/deliver to you.

Now, that doesn’t mean sitting in front of a wall of screens watching and analyzing people’s every move. You may need to do that at some point, but only after you figure out when, where and why the loss happened. If you have no way of detecting and documenting losses in real time or near-real time, then you’re never going to prevent losses. You can’t intervene to stop a loss if you don’t know when, where, how or why you need to act.

The second thing to remember?

Shrink is always an inventory problem stemming from a lack of data, which leads me to the third point (and most important) point: Shrink is not your only source of loss. It may not even be your biggest source of loss. However, you won’t know that if you don’t have data to tell you what’s really going on.

This is something that analysts from Retail Systems Research found retail “winners” to understand, as you can see in their extensive 2023 report. Look at pages 11-12. Look at how many different loss sources they’re trying to tackle – how many different opportunities they see to stop losses using the internet of things (IoT).

I know, the onslaught of news stories about theft, fraud and organized retail crime may have you convinced that THIS is the problem you need to focus on right now. And it is one of the problems you need to focus on because there’s no doubt people are walking out without paying. But if you only focus on POS bypass by your red shoppers, you’re going to either miss or create more problems that will contribute to greater losses.

For example, in an attempt to create “control points” at the point of sale – by forcing people to staffed checkout lanes or installing gates – you may inadvertently create choke points that drive away your “green shoppers,” the loyal customers and big spenders who are keeping you out of the red. Or you may miss the fact that your employees are tossing goods down the garbage chute for their friends to pick up or not properly trained on how to handle price matching, shelf-app price mismatches or coupons that aren’t scanning. You may also not appreciate the extent of your losses at the receiving dock or in your supply chain. How much product is arriving damaged, past expiry dates, or outside of acceptable cold chain temperature ranges?

In other words, people’s actions absolutely contribute to your losses. However, people aren’t typically the problem. A lack of data is the problem (i.e., not knowing when, where or why there are inventory distortions and whether those distortions are the result of actual shortages due to theft, missed scans/tag reads, or misreporting on received goods.)

That’s why the key to “loss prevention” is a loss detection program built on what my team and I call the four Cs: create, capture, consume, capitalize.

How to Effectively Detect Losses

There are lots of different ways to detect losses and pinpoint the root cause of the loss. I won’t be able to tell you which ones are best for you without sitting down and talking to you about your operations, your facilities, your digital footprint and more. However, leaning into the first three Cs of the “four C” strategy is imperative whether you’re trying to reduce losses within your retail store, warehouse, plant, sorting center, restaurant, hotel or equipment servicing business.

You must:

Create a way to track inventory movements and transactions and correlate people to those points in time inside and outside your four walls.

Be able to constantly capture data about inventory movements and transactions.

Have a way to consume all those data points in an aggregate manner and correlate them with people and places to create a record that details “what happened,” “when and where it happened,” and “who was involved.” This makes it easier to investigate why something happened so you can consider what you should do about it.

Now, I say this as someone who has been focused on loss detection/loss prevention throughout my career and not as the head of an RFID business (so I hope you’ll take it to heart), but almost 100% of the time, the best way to capture loss-related data is going to be with RFID technology. That’s because loss is an inventory problem, as I stressed before, and there is no technology that I have seen as effective as RFID at tracking inventory or equipment movements in real time. There are plenty of people who are completely unbiased and will back me up on this, including Dr. Read Hayes (a world-renowned criminologist who serves as the director of the Loss Prevention Research Council) and Dr. Bill Hardgrave (the founder of the Auburn University RFID Lab).

If their endorsement for RFID isn’t enough, just look at the endorsements being given by companies using RFID to stop a variety of losses:

UPS is putting an RFID tag on every package it handles now to make sure it doesn’t lose sight of a single one (and have to pay for that loss).

Walmart (and many other retailers) are now requiring suppliers to source tag goods in over a dozen product categories and rejecting items that are missing RFID tags upon arrival at the store to ensure they know what they have on hand so they can better measure what’s leaving their stores (whether paid for or not).

Hunt Country Components, a smaller manufacturer, is using RFID to report work in process to customers in real time (to help retain customers), eliminate under/over/mis ships that lead to financial losses, and simplify payroll (to prevent employee losses and reduce opex). You should really listen to the CEO tell his story in this interview when you have 20 minutes. He will sell you on RFID like no one else I know.

And I could share dozens of other stories that demonstrate why RFID is rising to the top of the investment list for those who are taking losses right now: there is no better way to confirm on-hand inventory or inventory locations and to report what is in a box, bag, bin, cart or pallet as it leaves the building. (Just look at where retailers ranked IoT systems (like RFID and next-gen analytics) on the impact list for their business in 2023.)

If you’re a manufacturer or retailer who wants to reduce your losses, you can use RFID to confirm which items were actually received from a supplier (versus what the supplier said they shipped or a dock worker said they handled). RFID also provides visibility into what items are still in the building, where they are in the building, which items have left the building, how those items left the building, and whether those items were cleared to leave the building (i.e., paid for or approved for forward distribution).

If you’re a warehouse operator, you can use RFID to confirm what you’ve received for forward distribution or storage, confirm when items were packed, when they were shipped and even when they were returned. Or, in the case of warehouses used for utility, public safety or healthcare operations, a quick read of RFID tagged items can tell you the current quantities and locations of critical supplies and equipment and automatically document when the items are pulled from the shelf or used to assist with restocking.

In hospitality environments, you can use RFID to maintain a chain of custody for food items or track the handling of recyclable or reusable utensils for compliance and inventory management purposes. We’re working with several major quick-serve restaurant (QSR) brands on these types of use cases. Though they aren’t as worried about theft, they are worried about losses resulting from waste, quality issues or non-compliance fines.

Now, to show you I’m not biased toward RFID just because I head up a business that sells RFID technology…

There are some items that won’t warrant an RFID tag right now, such as groceries, so you’ll need to track the movement of those goods a different way. I know you may be inclined to use a barcode scan, and that’s certainly an option considering every good sold today needs a barcode affixed to it somehow to process the transaction, especially via self-checkout and other self-serve POS methods. But part of the problem with using barcodes for loss detection and recording is that, if someone bypasses the POS or they think they scanned an item and they didn’t, you have no way of knowing that happened until the person and item are long gone. In fact, you may never know what happened to that item because a barcode is only a good source of information if it is scanned.

That’s why it’s better to use vision technology in situations where RFID may not be a viable option (i.e., with produce) so you can still track the movement of barcoded items that are not scanned.

In fact, there is a group of well-known technologists and supply chain/retail experts who recently dug into this very topic on the Industrial Automation Insider podcast. So, rather than me diving into it here, I’m going to encourage you to listen to their conversation to better understand when you should use barcodes vs. RFID vs. vision – or a combination thereof. They did an excellent job laying out the best approach in each scenario:

Long-time retail consultant Mark Thomson also made a strong case for moving to checkout scanners that incorporate cameras, AI and other vision technology in this piece:

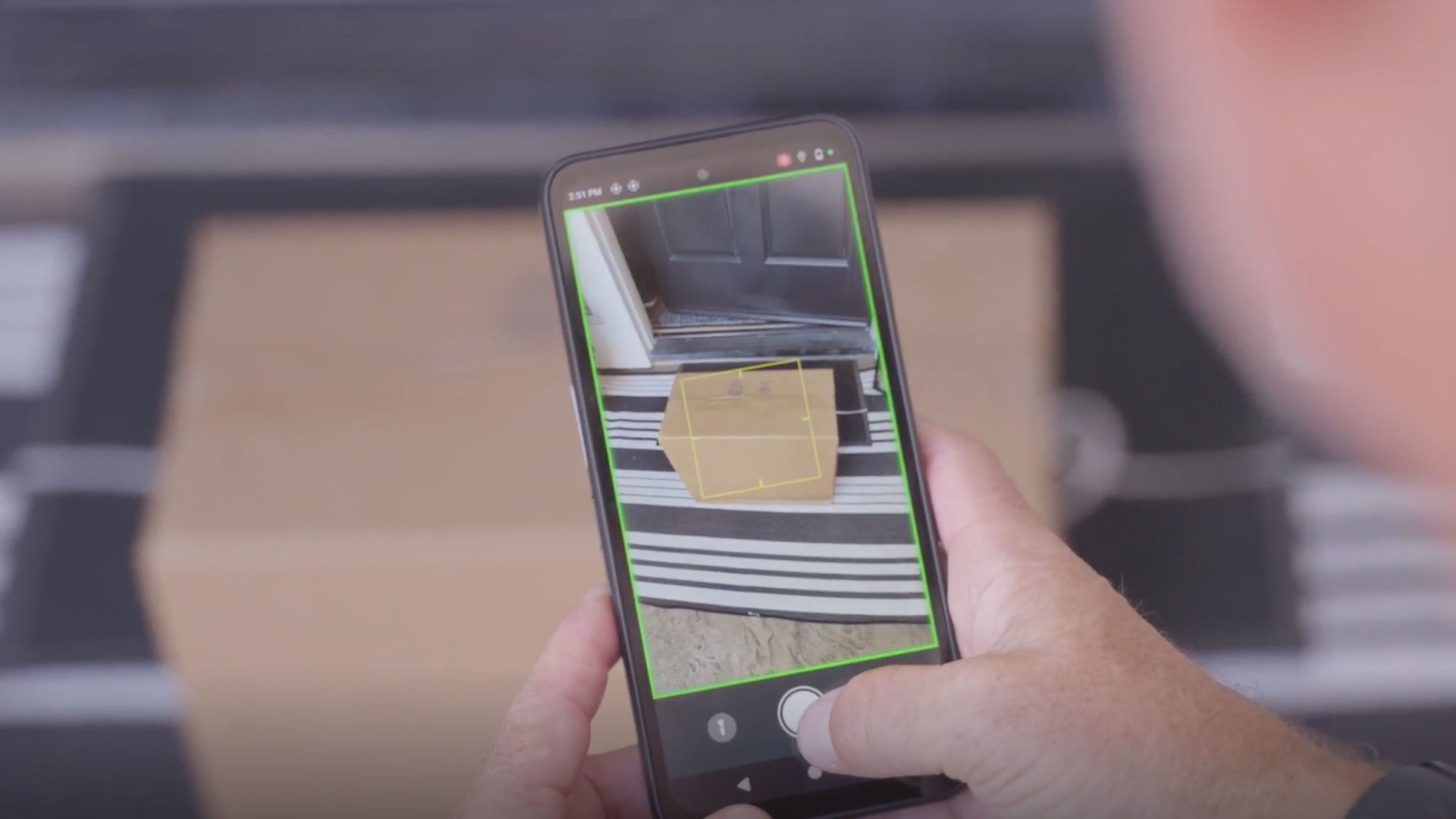

However, the reason I believe vision technology would be the next best choice to RFID, or perhaps even a good complementary tool alongside RFID, is that it can “see” and actively record when someone walks out without paying for something quite well. It can also work hand-in-hand with other technologies – like gates and alarms – to both report losses and help action an intervention. So, while you aren’t going to put an RFID tag on a can of peas, you might want to install some smart cameras around your facility that can see when that can of peas is picked up, put down, and either paid for or snuck out of the building. And you definitely need to put some technology in place that makes it easier for staff to report when that “lost” can of peas being reported by your inventory system is actually the result of damage or misplacement.

This won’t necessarily be vision technology but rather a combination of mobile computers or wearables with inventory management software. If an associate is unpacking a case of peas and three cans are totally smashed, they need to be able to take a quick picture using a wearable or handheld mobile computer to document the damage and report that they disposed of those peas so that you don’t end up with inventory distortion in your system. Or if they come across a misplaced can of peas – maybe a shopper picked them up and decided at checkout they didn’t want them after all – then the associate needs to be able to pull up the planogram to know where that can of peas belongs. This way they can fix it and the person doing inventory doesn’t count the misplaced item as a loss.

This ability to connect with and update the inventory system in real time is key, no matter which hardware you use to capture and record transactions or inventory movements. You must be able to ingest data from multiple edge devices – cameras, RFID readers, barcode scanners, wearables, mobile computers, POS registers, and more – and connect the dots between all the data points captured at a moment in time. Otherwise, you’re not going to be able to figure out where your losses are occurring, why they’re occurring, and who to talk to about the losses. (“Is the cashier not putting in the right SKUs for organic produce? Is the stocker not documenting damaged peas? Is law enforcement building a case against an organized crime ring?”)

You can’t stop a leak if you don’t know where the leak is occurring, and you can’t ID the source of a leak if you can’t see what’s happening. A plumber can’t tell you over the phone if the water seeping out from under your tub is coming from the drain, the strainer, the overflow valve, or somewhere else. They must visually inspect it. Well, no one can tell you if your shrinkage or financial losses are coming from employee theft, shopper theft, employee mistakes in receiving, improper scanning of items during order fulfillment or something else entirely…unless they can physically see inventory movements and transaction records. It’s that simple.

So, if you’re truly worried about losses anywhere in your operation, let’s sit down, talk about what you think is happening, then draw up a plan to confirm if your suspicions are true using technology (like RFID, vision systems, inventory software, edge devices, etc.). That’s the best way to see if you’re right or if there’s another reason for the leak.

Once we have the data at hand and we know what you’re dealing with, then we can talk about the fourth “C”: Capitalizing on these insights.

“What Can I Do to Stop the Losses? And What Should I Do?”

They say, “Inaction breeds doubt and fear,” but I’ve been talking to a lot of business leaders in recent weeks who are fearful of the consequences if they take action to reduce their losses, and their concerns are valid.

If I approach an employee about a mistake they made, will they accept the feedback and welcome more training or will they feel deflated and quit?

If I report a shopper or employee to law enforcement for theft, will the evidence be strong enough to result in a conviction? Is it even worth the effort or the risk of retaliation when they’re back on the streets? Can I just talk to the employee, put them on probation and retrain them hoping they’ll correct their behavior? Can I put measures in place to better identify a repeat shoplifter when they come in and somehow prevent them from stealing again?

Am I putting the safety of my employees and customers at risk if I have loss prevention teams intervene when an alarm goes off or an RFID reader or camera flag a POS bypass? Should I just let the person walk out?

How should my staff respond when armed shoplifters come into my store? Or even just a group of people who are clearly coming to clean house?

If you remove self-checkout lanes to drive all transactions to a staffed register, or lock up health and beauty items, am I creating a control point or a choke point that will drive other shoppers – paying shoppers – away because of the added friction?

If I put extra verification process in place at the dock to ensure inbound and outbound items are properly captured, am I creating more efficiency or friction for my team? If it’s the latter, what are the consequences? Delayed shipments? Unhappy customers? More work for employees who are already stretched thin? Delayed response times to emergency calls?

Unfortunately, there is no blanket “best practice” to apply here because some losses can be mitigated with process changes (and technology-powered control points) while others would require human intervention that could present personal safety concerns. So, while you should absolutely act on the information you receive from loss detection systems, how you should act is going to require consultation with multiple stakeholders. For example, if you want a security guard or other staff member to physically intercept someone trying to evade the POS or steal something off a loading dock or trailer, talk to the people who specialize in workplace safety practices to understand the risks versus rewards. If you want to stop organized retail crime – or any sort of organized theft and fraud – talk to law enforcement. Understand what kind of data you need to collect, and how you should stack it, so that you can file an enhanced evidence claim and enable to open a case that can be effectively investigated and prosecuted.

When you have red shoppers who are smart enough to stay under the felony threshold with their thefts, or you have violent criminals causing problems, the only way you can really get stop them is to document and prove through transaction, RFID and camera records that show the crime, and repeat crimes, in an indisputable manner.

Similarly, talk to people who understand returns fraud. They’ll advise on how you can use the loss detection data you capture via RFID to stop someone from returning a stolen item.

There are also people who spend all day developing AI-based software systems that mine your data and identify patterns in e-commerce, shopper and employee behaviors beyond the retail POS so you can address losses resulting from dead inventory, improper inventory mixes, and regulatory non-compliance fines (such as cashiers bypassing age verifications for alcohol sales). Please talk to them if you’re in the retail or hospitality business.

And if you’re taking losses from underutilized or improperly scheduled labor, or shippers who are losing inventory in transit, you’ll want to check out these two very different trailer tracking solutions that are helping some in the supply chain plug those leaks.

In Other Words

Loss prevention is an outdated notion that’s based on a “toolbox of sandpaper” as my colleague, loss prevention/detection expert Randy Dunn likes to say. It’s all friction.

Loss prevention works against the fundamental premise of retail, which is a frictionless, convenient shopping experience. Creating choke points or acting on assumptions versus facts will deter your best shoppers, leading to sales losses that exceed other forms of shrink.

Even in healthcare or public safety environments, the focus should be on loss detection so that equipment and supplies are restocked in a timely manner. Loss prevention does nothing when the medicine is missing or oxygen tanks depleted. Same with quality or theft-related losses in the supply chain. While you should absolutely lean into environmental sensors, RFID, machine vision, computer vision and other technologies that can track inventory movement and monitor current location and conditions, it’s going to be hard to prevent quality or theft losses if you can’t detect when there’s an anomoly in the good or shipment. If something is sitting on the tarmac too long, you need to be able to detect that in real time. That’s how you prevent the loss.

So, I hope you’ll take a few minutes right now to send me a note or get in touch with some of my colleagues who are well-versed in loss detection strategies for your industry.

We’ll help you find out what’s really causing those losses by connecting you with people both inside and outside of Zebra who have the technology tools and experience you need to create a strong loss detection system. Together, we can explain what you need to capture and consume/correlate the data required to put a very prescriptive treatment plan in place – so that you can prevent the “preventable” losses. (The ones that result from mistakes, improper training, exhaustion, oversights and more.) And if you want to take a more aggressive approach to organized and violent crime, we can connect you with experts like Dr. Hayes who can work with you and your asset protection teams on the best approach in those situations.

###

Related Insights:

There is More Than One Way to Track Trailers (and Inventory) on the Move. This Retailer Proved It.

Retail Has a $60+ Billion Dollar Blind Spot, but Theres One Technology That Can Help Reduce Shrink

Brent Brown, Global Vice President and General Manager, Advanced Location Technologies, Zebra Technologies

Brent Brown is a Senior Retail Executive with over 30 years in the technology industry. Brent’s experience spans global industry leadership with a track record in building, leading and executing industry solutions/services, aligning program management delivery organizations and delivering on organization transformational programs.

Brent currently serves as the Global Vice President & General Manager of the Advanced Location Technologies (ALT) business unit at Zebra Technologies based in Lincolnshire, IL. In this role, Brent leads all software and hardware engineering efforts as well as strategic go-to-market activities for Zebra focused on active and passive RFID technologies across all industries and vertical markets.

Prior to joining Zebra, Brent worked both the software and hardware industries with companies such as Tandem, Compaq, Hewlett Packard, and Sensormatic. He has led sales teams, business development groups and software/hardware engineering practices. As a result, Brent is a seasoned customer advocate with exposure to some of the largest customers in North America, Europe and Asia. He is very passionate about delivering value to enterprise customers and end consumers through the innovative use of technology and services.

Brent currently lives in Toronto, Ontario, Canada with his wife Nancy. He has three married children and one new grandchild. He loves being active in sports such as hockey, golf, volleyball or anything that is competitive.