BE Switchcraft Sees Manufacturing Process In Real Time With RFID

BE Switchcraft replaced its barcode scanning solution with RFID technology that now provides real-time visibility into each stage of the manufacturing process.

Zebra Success Story: BE Switchcraft

Overview: Manufacturing Challenge

Implement a more efficient way to track the movement of switchboards along the manufacturing process and gain real-time visibility into the status of each customer order.

Benefits / Outcomes

- Real-time status of all products being manufactured

- Reduction of manual processes

- Improved customer deadline management

- Improved monitoring of manufacturing processes

- Greater staff adoption of tracking solution

Customer

BE Switchcraft

Adelaide, South Australia/Australia

Partner

Industry

Manufacturing

Solutions

About BE Switchcraft

Located in the city of Adelaide in South Australia, BE Switchcraft is a leading manufacturer of customised electrical switchboards for large building applications. Its customers extend across its home state of South Australia and as far as Papua New Guinea.

In operation for over 50 years, BE Switchcraft’s switchboards are now in use in iconic buildings such as the Parliament House Canberra, Adelaide Convention Centre and Port Moresby Football Stadium.

From switchboard design and manufacturing, lighting control and room automation systems, to energy management systems and specialist laser cutting and labelling services, BE Switchcraft has invested heavily in technology to ensure the company is fulfilling its customers’ expectations.

The Challenge

As the business grew from manufacturing 100 switchboards a month to over 200 of them in the same period, BE Switchcraft needed to find improved ways to track the status of its projects.

Due to the critical nature of its switchboards, BE Switchcraft must ensure that deadlines are met and its customers are accurately informed as to the status of their orders.

The manufacturing of switchboards involves many steps on the factory floor. Therefore, having the visibility of each step of the process and refining those processes to enhance efficiency has been critical in managing the growth of the business.

The management team needed visibility into what was happening on the factory floor. Tracking the status of each switchboard being manufactured was critical to ensure they were being produced in accordance with the customers’ requirements.

The journey began with manual processes and inputting of data into its enterprise resource planning (ERP) system. Besides being an inefficient and cumbersome process, the gathered data was out of date by the time it could be analysed, which was ineffective.

The manual process was replaced with a barcode scanning solution that included the documentation that travelled with each switchboard being scanned at different stations along the manufacturing path. This solution was short lived as the hands-on need for staff to scan each document proved to be unreliable and inefficient. BE Switchcraft needed a better solution.

We need to give our customers accurate deadlines as to when their switchboards will be ready, and we could not capture that in our previous systems. Monitoring the status of orders in real time as well as monitoring the manufacturing process and the efficiencies of it were key.

The Solution

While the barcode scanning solution for tracking the project status had its merits, the staff needed an easier way to gain real-time visibility into the process. BE Switchcraft explored alternative data capture solutions which led to an RFID solution.

Not afraid to adopt new technology, the team at BE Switchraft moved quickly to replace its barcoding solution by engaging Zebra’s partner, Datanet, for assistance. The RFID solution chosen involved the use of the Zebra FX9600 fixed RFID readers, RFID antennas and an RFID label printer.

“Configuring the RFID solution was surprisingly simple. The FX9600 fixed RFID readers were easily implemented onsite, and with a little integration work, we are successfully capturing data from our factory floor in real time into our MYOB ERP solution,” said Anthony Spadavecchia, Managing Director, BE Switchcraft.

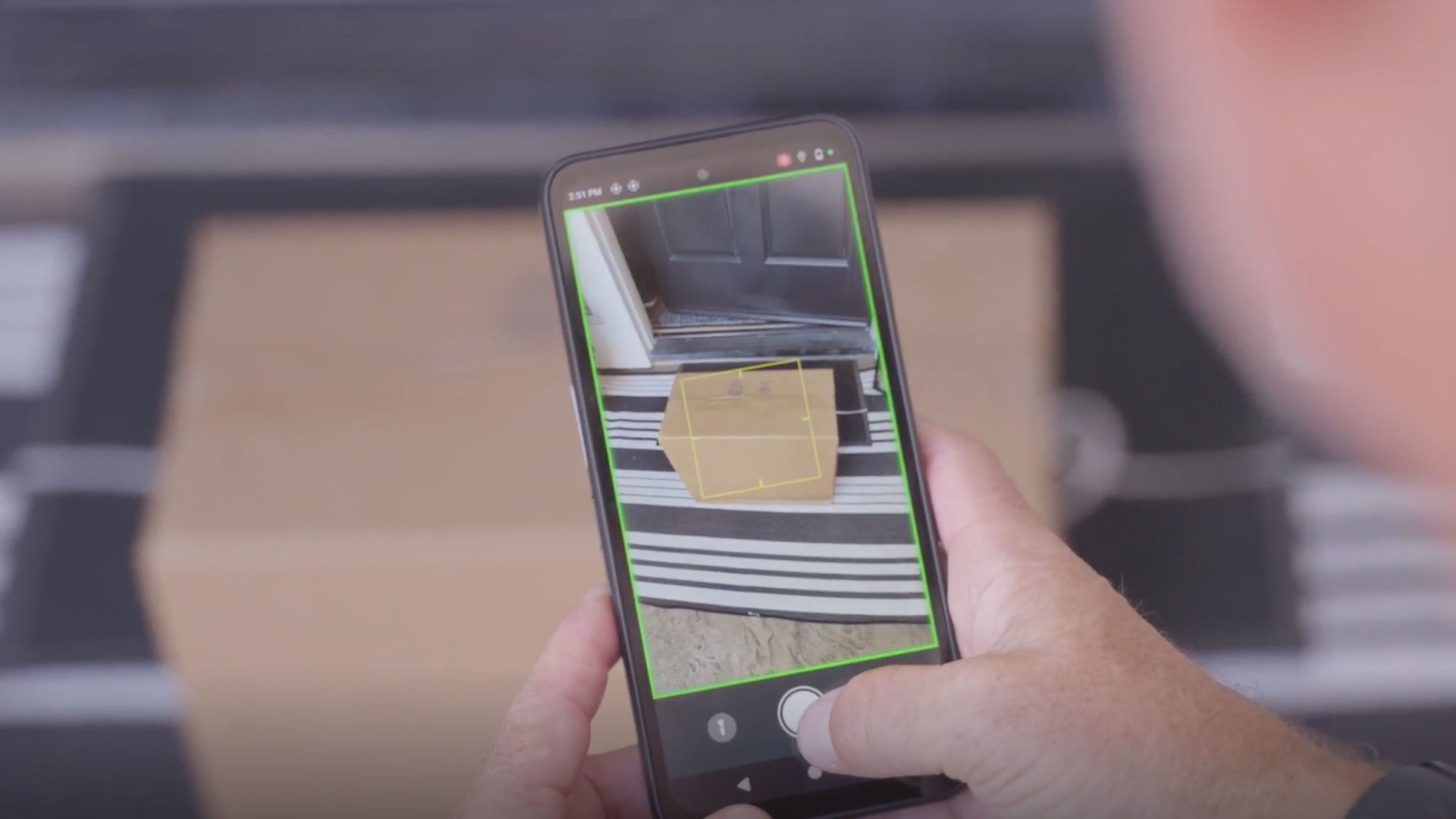

The documentation that accompanied the projects was still deemed a suitable point of data capture to track the movements of switchboards across the manufacturing process using RFID. The team could have real time visibility into each stage of the project based on the location of the documents. An RFID tag is now printed and placed on the bundle of documents to allow for easy reading via RFID antennas that are located at key steps in the manufacturing process.

As the projects move along the manufacturing path, the RFID tags on the accompanying bundle of documents are read via RFID antennas that are located at key steps in the manufacturing process. Reading the RFID tags is as simple as placing the bundle of documents near the RFID antenna.

The hub of the RFID solution is the Zebra FX9600 fixed RFID reader. This reader is easily integrated into existing networks via Wi-Fi or Ethernet and offers industry leading read rates and accuracy, even in dense RF environments.

The FX9600 is available in 4-port and 8-port models, allowing for multiple RFID antennas to be connected which allowed BE Switchcraft to match the different requirements within its factory. Datanet assisted BE Switchcraft with the deployment of the RFID solution, providing the company with the hardware and advice needed to assist the internal IT team at BE Switchcraft to set up the solution.

The Zebra Difference: Outcome and Benefits

The use of a simple RFID solution at BE Switchcraft has empowered managers to stay in control and improve manufacturing processes as well as the accuracy of product delivery and the advice given to customers. The ease of use of the RFID solution has also increased staff support of the data capture process beyond barcode scanning which has helped to significantly improve the integrity of data.

The most important result of implementing the RFID solution is gaining access to real-time data. While manual processes provided a delayed view of the status of products in manufacture for up to two days, BE Switchcraft is now able to access instant information. This data is integrated with its MYOB ERP solution providing valuable updates on the status of each project as well as financial data associated with the projects in production.

With greater visibility of the manufacturing process, improved financial data visibility and the ability to better manage customer expectations, Zebra’s RFID solution has paved the way for further process refinements. And with a robust solution in place, BE Switchcraft now has a solution that will support further its business growth.