Leverage real-time presence, absence, and fill verification for case-packing and kitting with 2D/3D vision

Automate presence and orientation checks

Iris GTX Smart Cameras with up to 16 megapixel resolution provide a simple solution for 2D product inspection. Mounted above production lines, smart cameras capture and process images of packed or assembled products, such as meal kits, prior to sealing. Following programmed rules, the smart cameras verify whether all expected components are present in the correct quantity based on pre-defined rules or thresholds. The Iris GTX passes pass/fail judgments to a programmable logic controller (PLC) or robot to trigger rejects, or alarms as required.

Add 3D profilers for fill and position control

Where 2D images provide inadequate context or perspective for accurate pass/fail judgments, 3D vision provides a robust solution. Zebra AltiZ 3D profilers scan product assemblies to create height maps of trays and cases at full production speed, revealing missing, underfilled, or misplaced items that 2D alone can miss. The profilers measure compartment volumes accurately in one pass - even on low contrast or shiny contents. These results can be used to supplement 2D checks to provide a universal pass/fail decision to the programmable logic controller (PLC) to stop, reject, or route items off the line. By combining 2D and 3D vision, teams gain reliable inspection with fewer false rejects and faster recovery.

Prove quality and optimize with production data

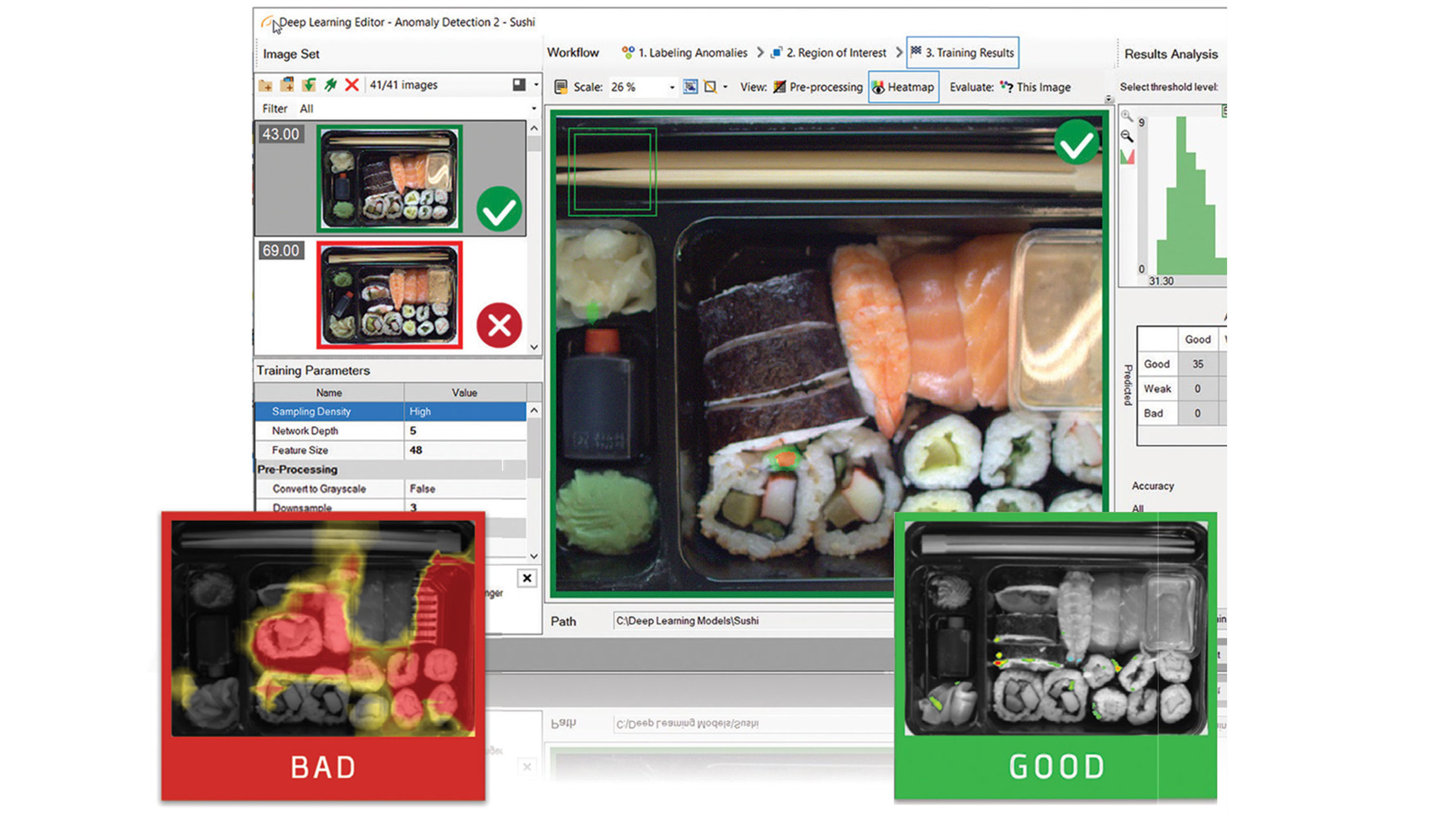

Aurora Design Assistant is an intuitive flowchart-based vision software that provides a comprehensive development environment for product presence/absence checks, incorporating 2D and 3D technology. Customizable operator views can be developed within Design Assistant to provide real-time insights into inspection performance, accessible remotely from a computer, touch-panel PC, or Human Machine Interface (HMI). The software includes built-in change control features such as project change validation, role-based permissions, and offline simulation for non-disruptive tuning.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.