Scale flat panel display inspection with fast, accurate machine vision for higher yield optimization

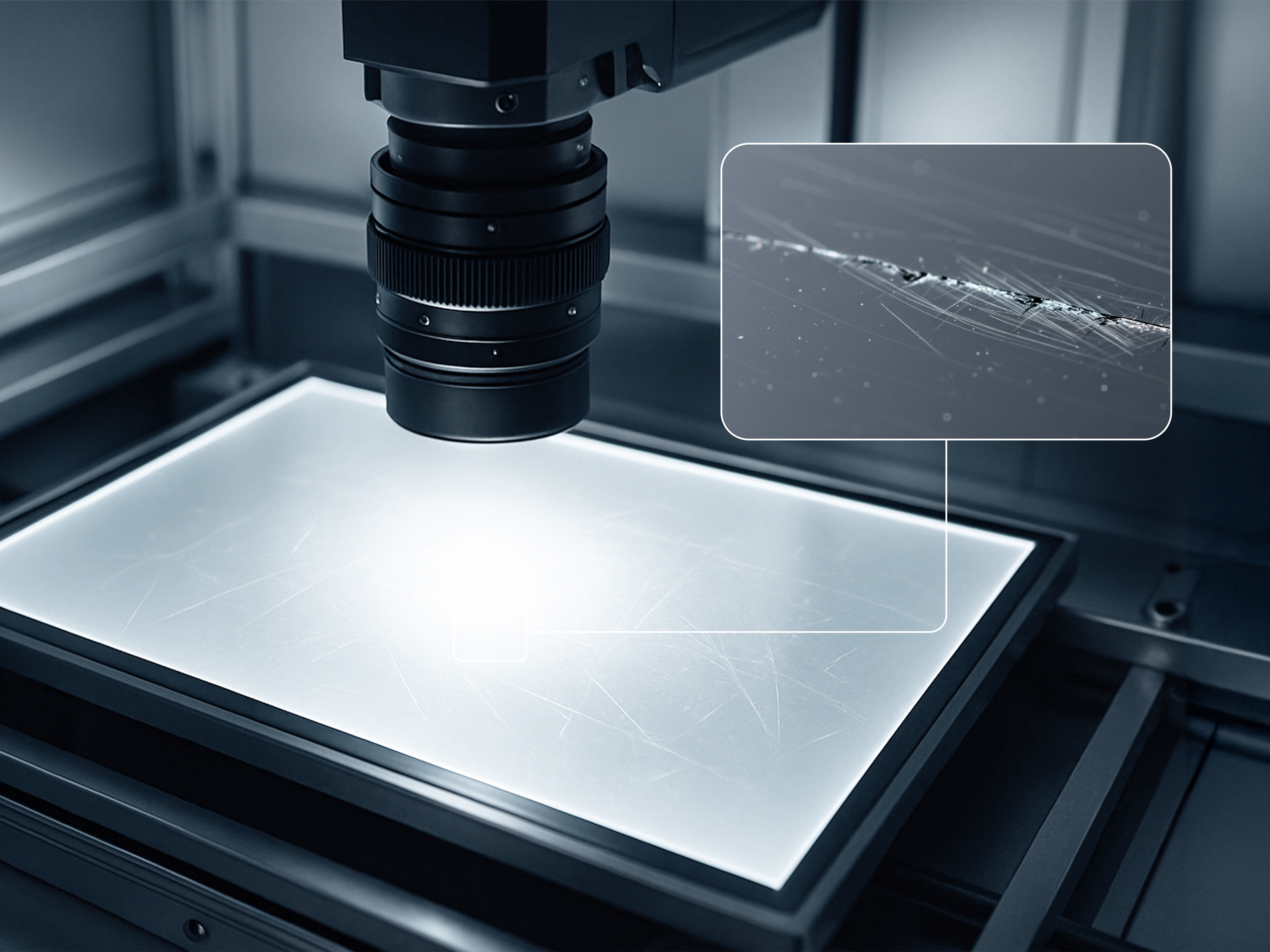

Detect FPD defects

Rapixo frame grabbers enable high-resolution, high frame rate image capture, which is essential in detecting minute defects in modern FPD production. The Rapixo Series is optimized for these demanding vision applications with support for the highest bandwidth camera interfaces currently available, including CoaXPress-over-Fibre, CoaXPress, and Camera Link. Pro models in the Rapixo Frame Grabber range come with Field Programmable Gate Array (FPGA) support for optional image processing offload from host computers.

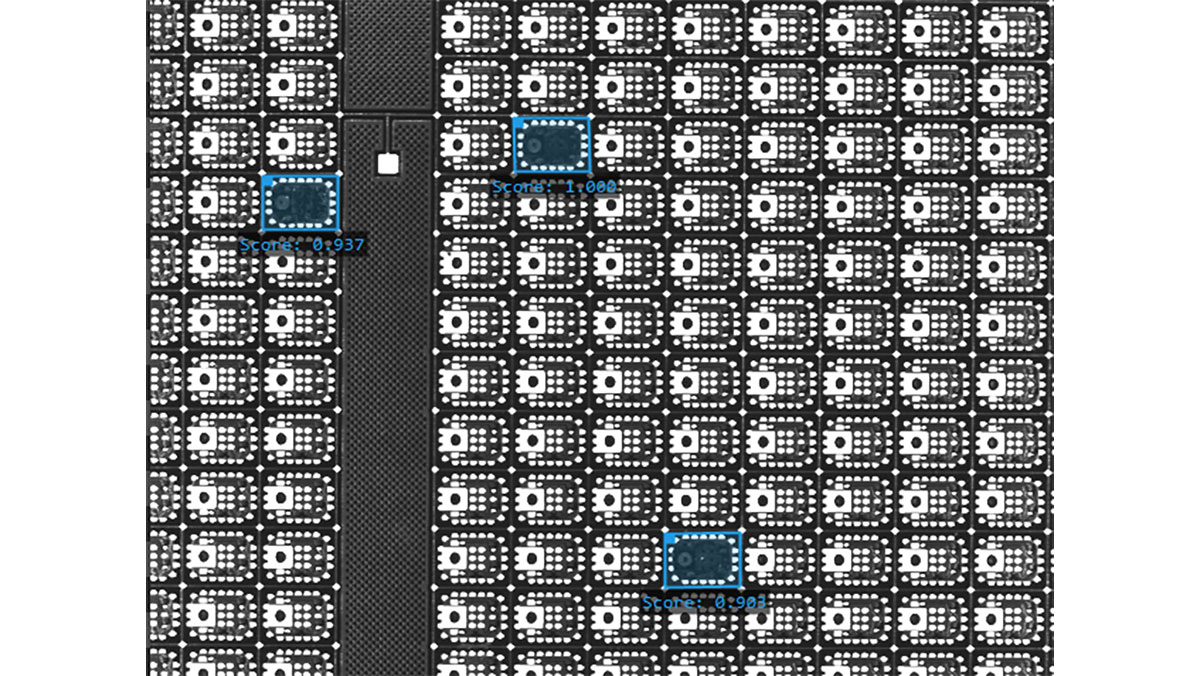

Transform FPD inspection data into enhanced process control and traceability

Zebra Frame Grabbers are designed to pair with Aurora Imaging Library Software Development Kit (SDK). Within this software, users can optimize the image processing for their FPD inspection at code-level by generating custom FPGA configurations in C/C++. Aurora Imaging Library also hosts a wide selection of software tools for image processing, analysis, annotation, and archiving to accelerate application development and reduce the time required to bring new FPD inspection solutions to market.

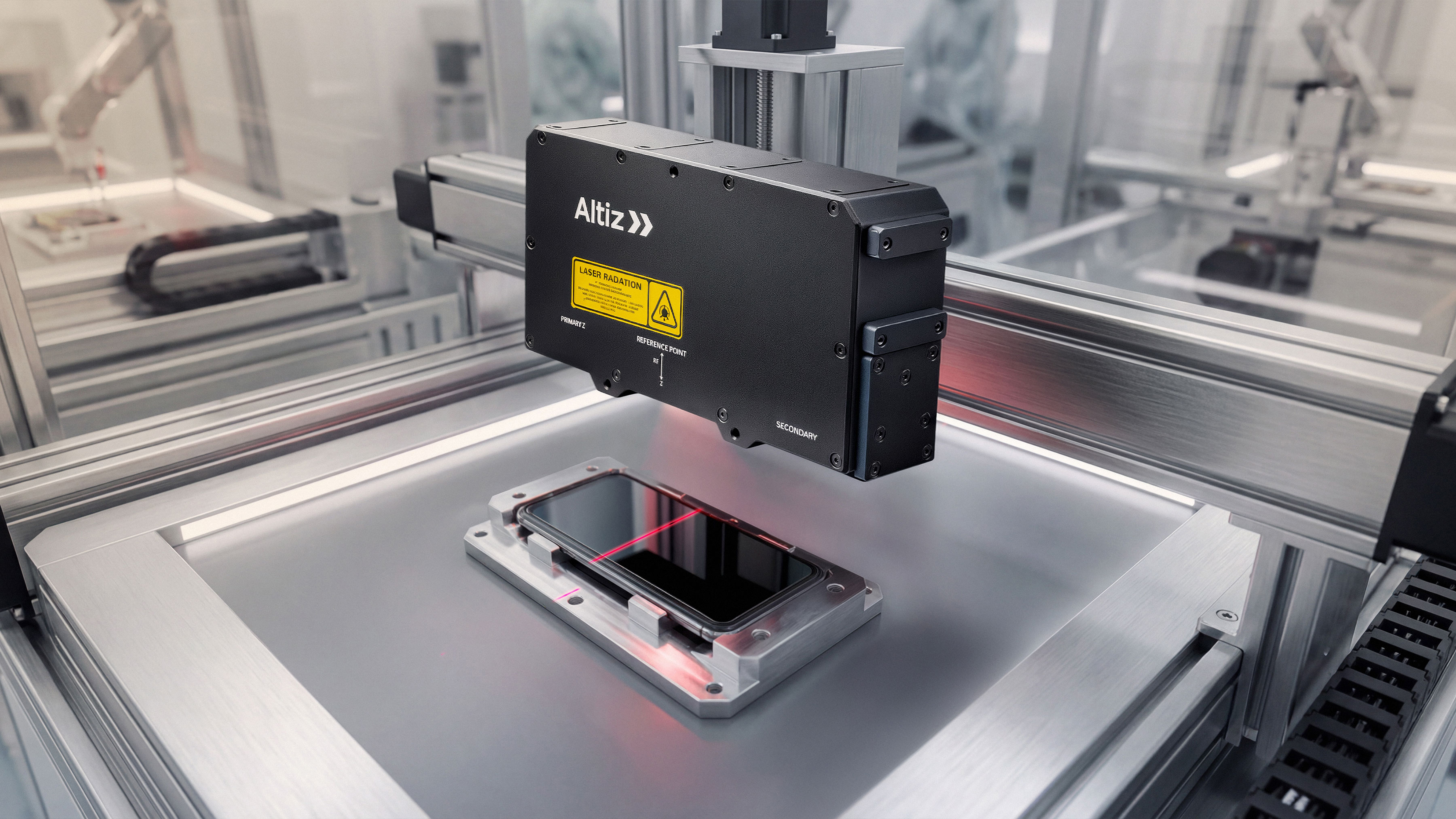

Accelerate alignment accuracy

The AltiZ 3D Profile Sensor speeds positioning and alignment before and after bonding of FPD components. Its dual-camera single-laser design captures high‑density 3D profiles with minimal occlusions, enabling precise fiducial finding, edge measurement, and flatness/warp checks to micron‑level accuracy even on reflective surfaces. Non‑contact 3D measurement protects fragile glass surfaces of FPDs while confirming height, tilt, and planarity. AltiZ results guide stage movements and verify placement against desired tolerances.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.