Automate end-of-line label checks to reduce chargebacks, meet compliance, and protect consumers across food, beverage, and pharma operations

Verify print quality at line speed

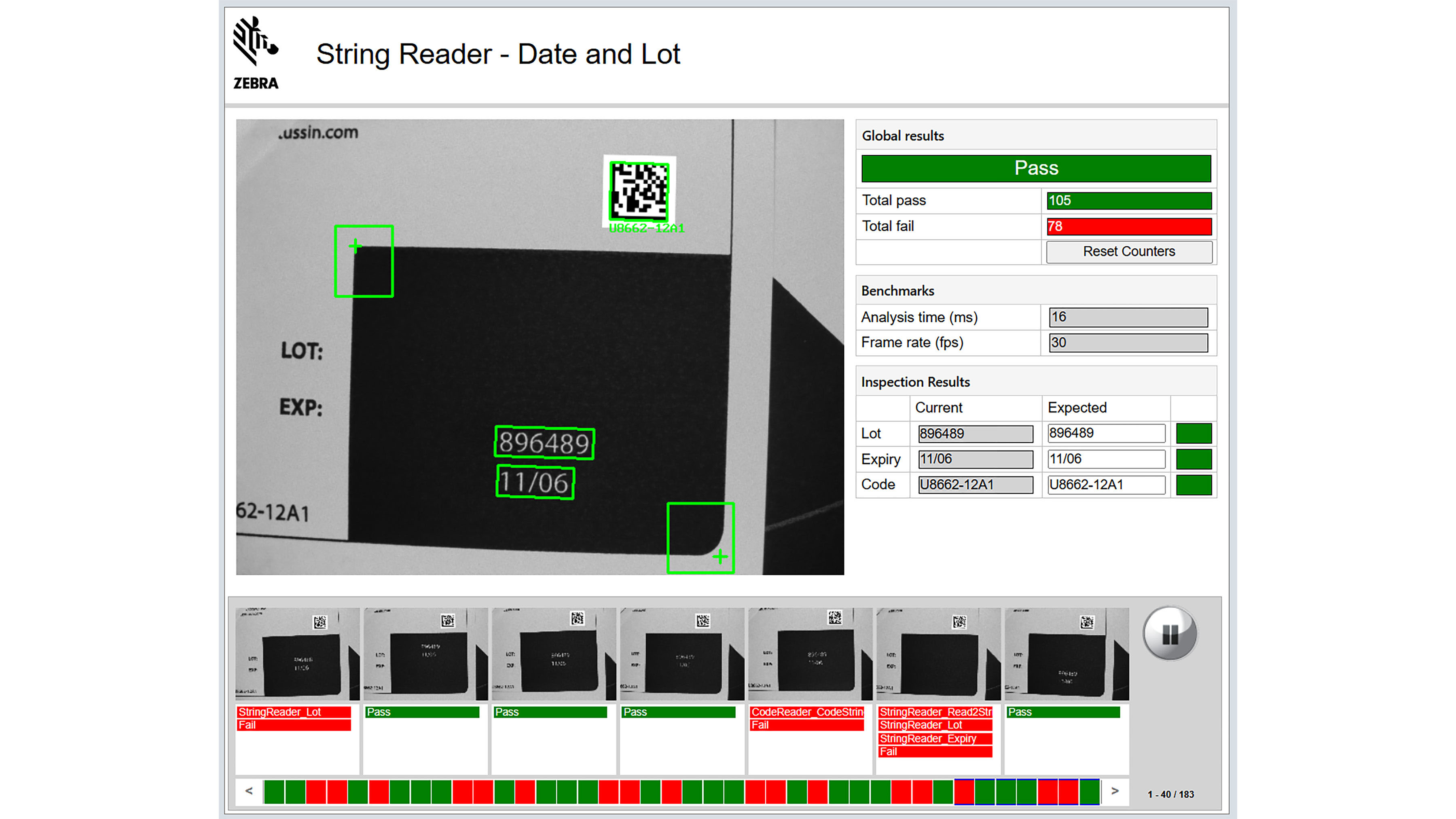

Zebra Fixed Industrial Scanners help ensure high-quality verification for simple label checks by reading and validating 1D and 2D codes, while detecting issues like low-contrast, damaged prints, missing labels, or quiet-zone violations. Equipped with optional vision tools like Deep Learning based OCR, Zebra Fixed Scanners can also capture human-readable text strings such as date codes, batch numbers, or allergy warnings for verification against expected values.

Confirm label contents automatically

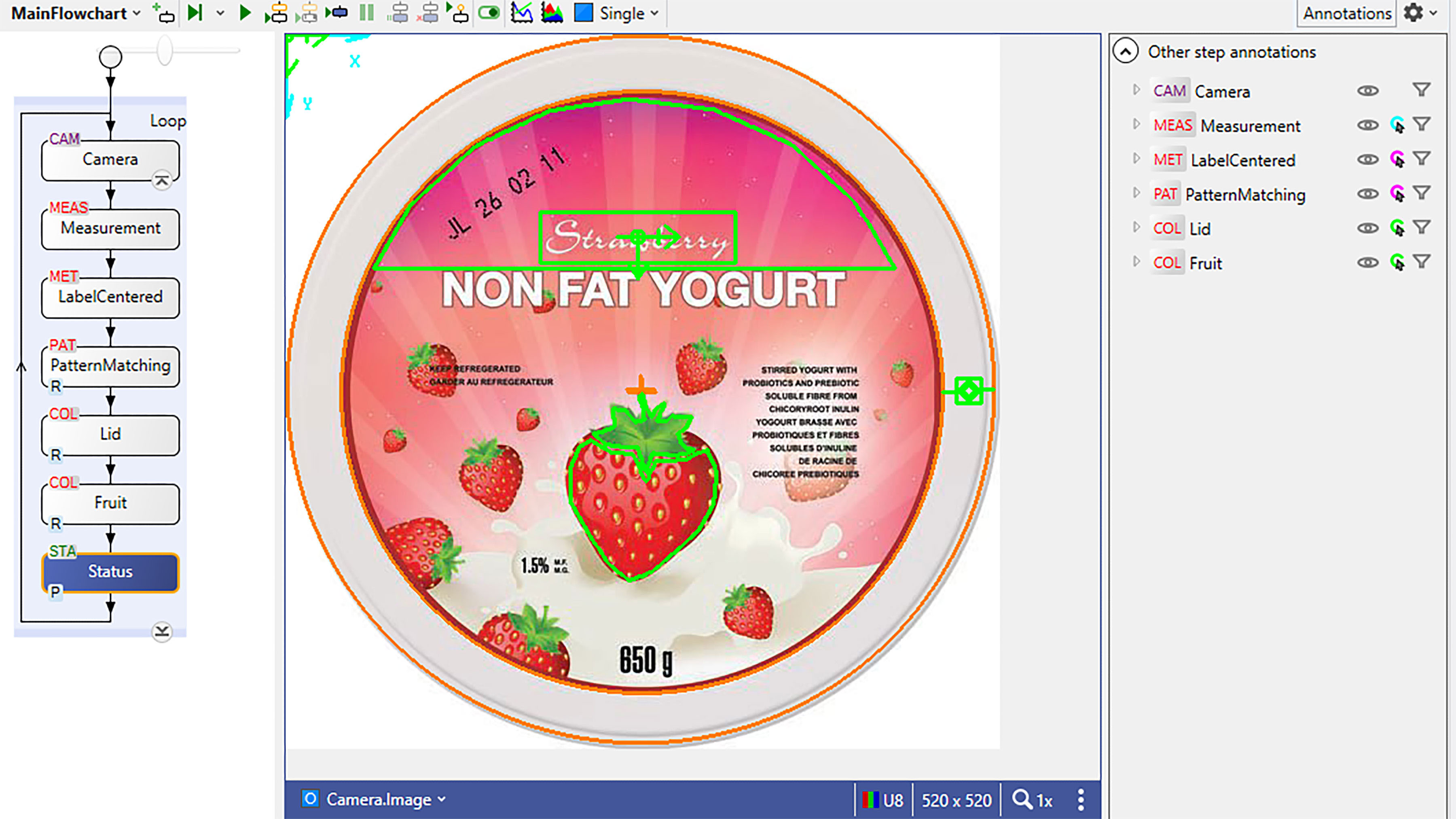

The Zebra Iris GTX smart camera provides a robust solution for comprehensive label verification applications, offering 2–16 MP CMOS sensor options, powerful on-device processing, and real-time I/O with a wide range of industrial communication protocols (such as EtherNet/IP, PROFINET, Modbus, CC-Link IE Field Basic, and more) to enable in-line pass/fail decisions directly at the edge. Beyond validating the presence and readability of required fields, such as ingredients, allergens, date codes, lot numbers, and regulatory marks, the Iris GTX can also be programmed to inspect labels for issues like damage, poor print quality, and other defects.

Close the loop with quality records

Iris GTX inspections are developed in the intuitive drag-and-drop Aurora Design Assistant software. In addition to application development, teams can build and deploy a custom web-based operator HMI within Aurora Design Assistant for real-time monitoring. Once an application is deployed, Design Assistant captures images, processes results based on programmed logic, and hands off results to automation and enterprise systems. Images of rejects can be stored for annotation with date/time stamps for audits and root-cause analysis to help identify and rapidly remedy issues such as printer drift, applicator misalignment, or artwork issues.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.