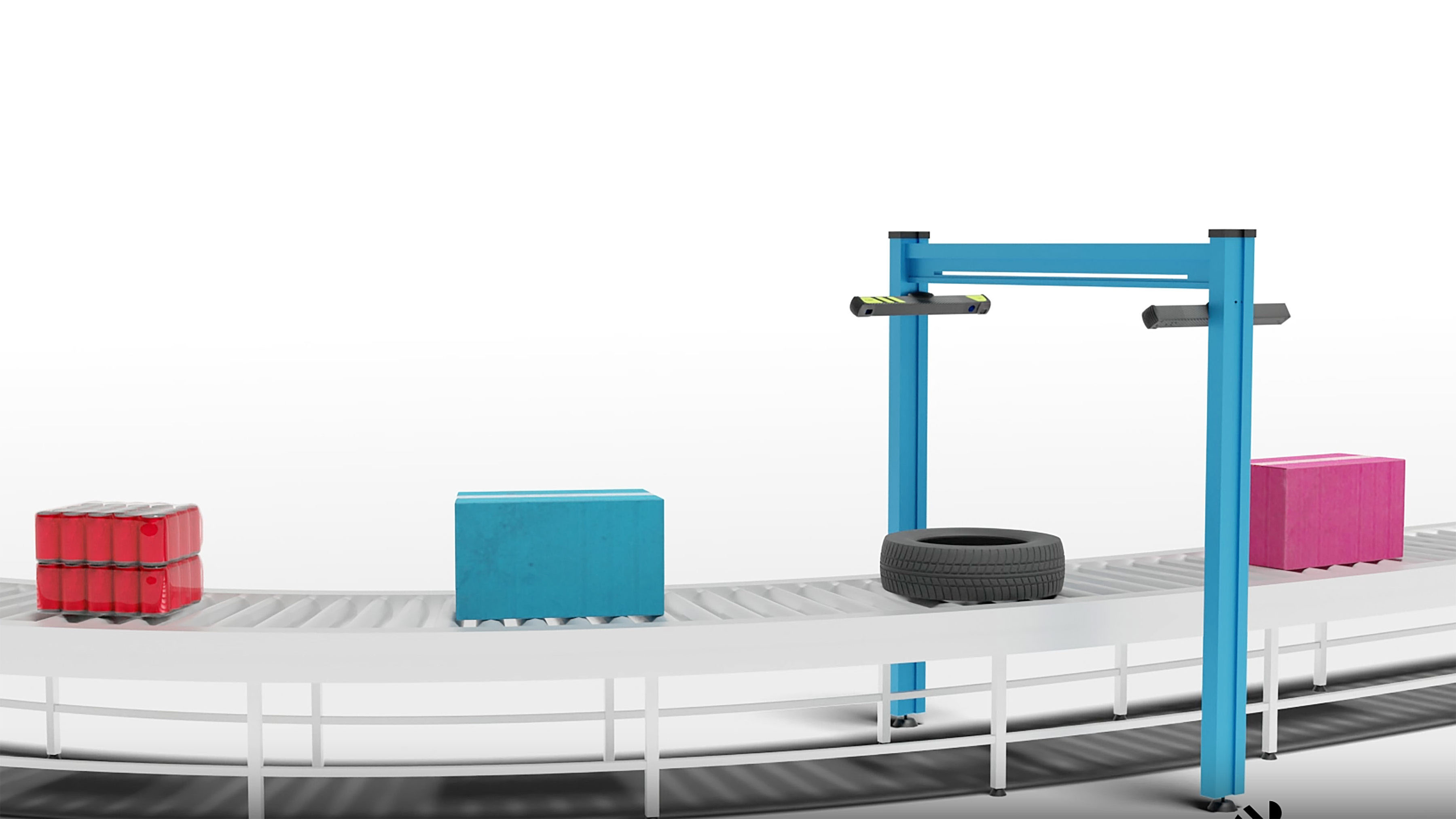

Automate 3D package dimensioning in sortation to route by size with accuracy, connect data to your WMS, and turn measurements into throughput, space, and cost gains

Automate 3D dimensioning on fast conveyors

The Zebra 3S Series 3D sensor delivers reliable package dimensioning on high-speed conveyors. Parallel structured-light projects multiple patterns and reads the returns to compute length, width, height, and orientation with motion tolerance while maintaining accuracy during vibration or rotation. The system classifies parcels by size in real time, outputs confidence scores, and flags low-confidence or out-of-range cases for review. Exceptions can be routed to a dedicated lane or station to reduce rework and stabilize throughput.

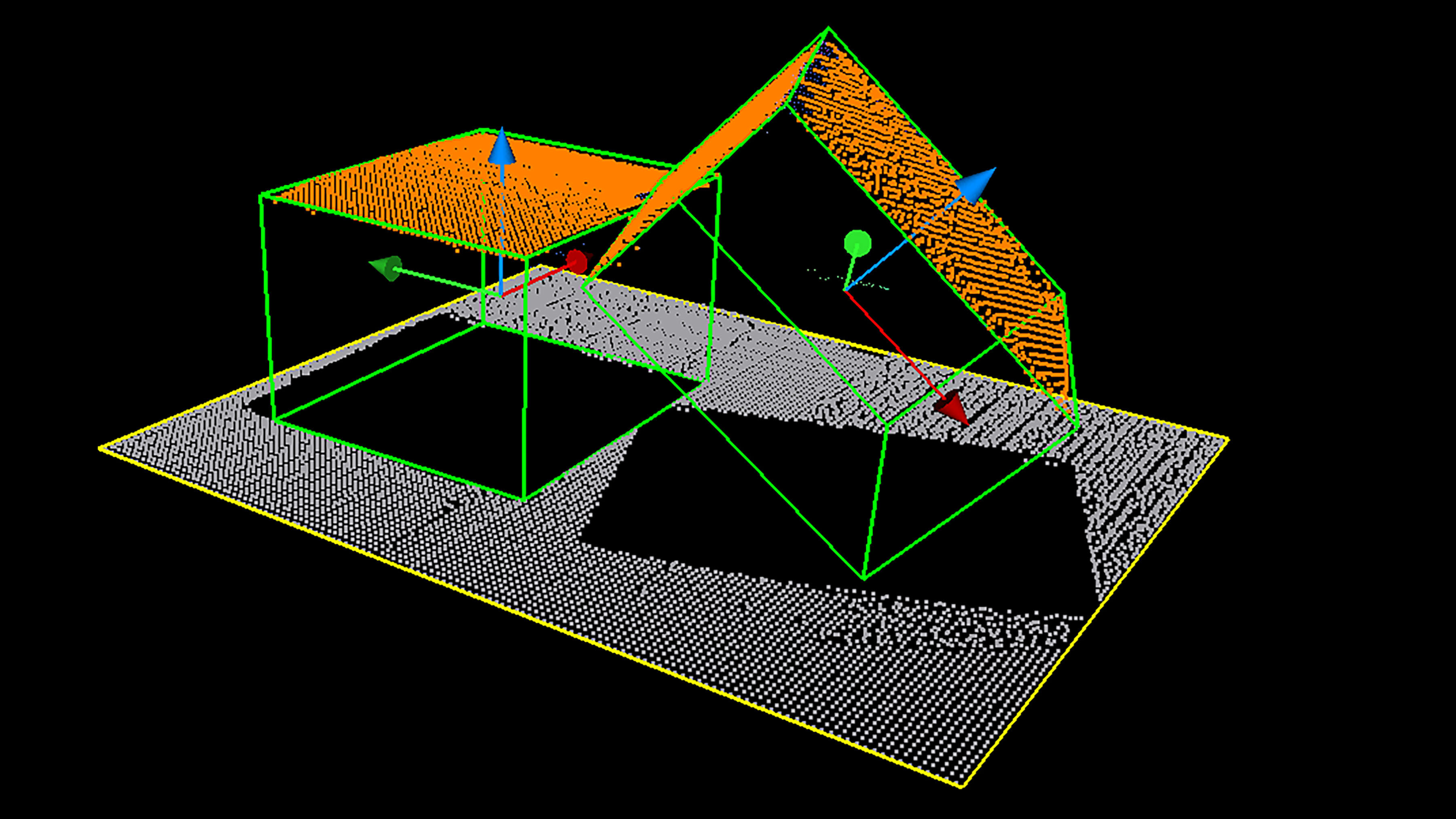

Use software to manage, integrate, and act on dimensions

3S Series 3D sensors can be set up and deployed using Zebra Aurora Design Assistant machine vision software. 3D acquisition, analysis, and processing capabilities enable users to quickly and easily develop their application in an intuitive drag-and-drop flowchart interface. The BoxFinder tool within Design Assistant locates one or more box-like objects in a point cloud, returning the position, orientation, and dimensions of each located object.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.