Use smart cameras, no-code development, and deep learning to catch defects in medical device assembly

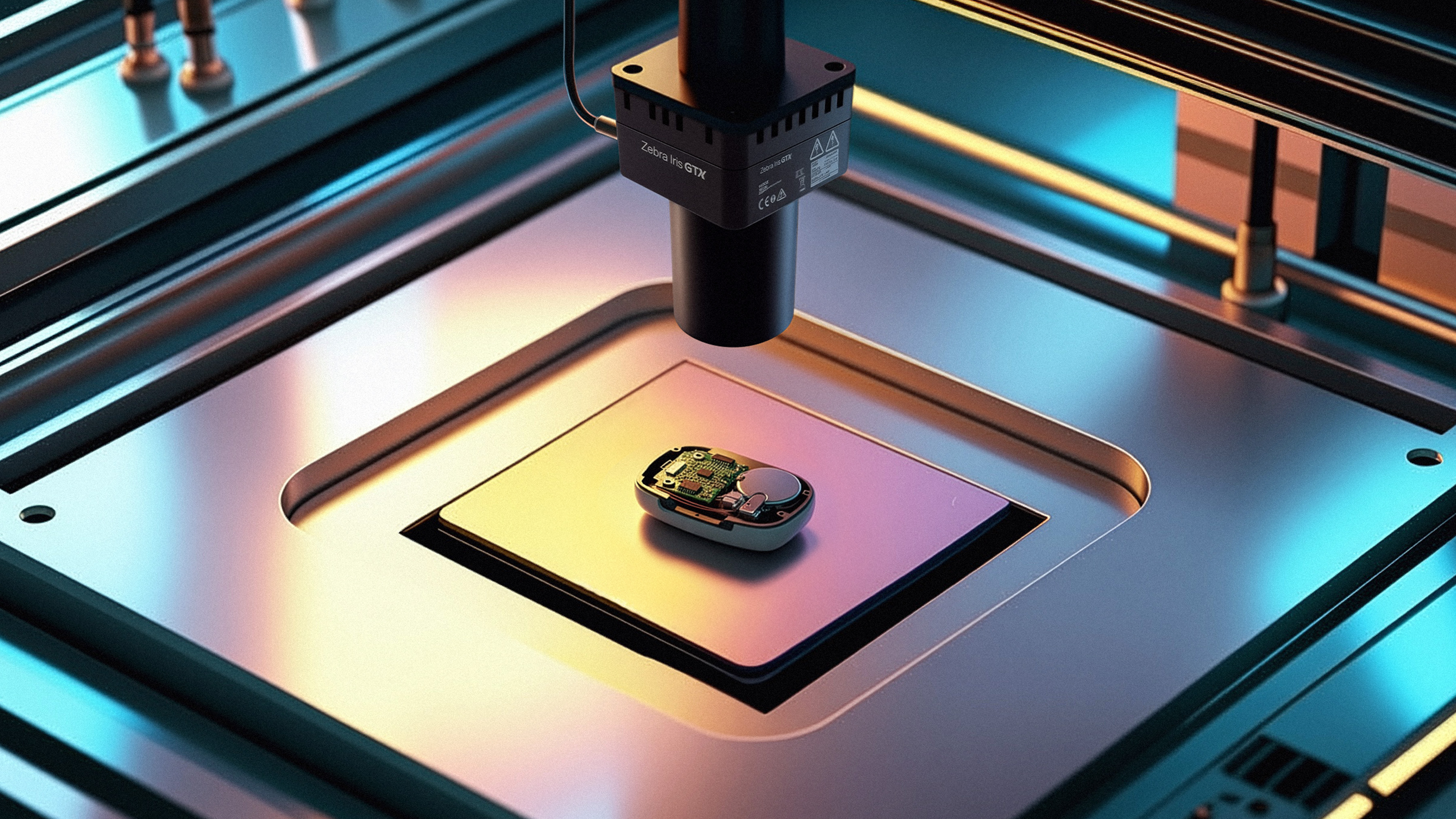

Automate inspection

Zebra Iris GTX smart cameras serve as a versatile platform for in-line quality checks, combining high-resolution sensors and on-camera processing to capture crisp images and execute inspection tools at assembly-line speeds. They can confirm the presence, position, and alignment of screws, connectors, and labels, plus verify seating, polarity, orientation, and cable routing. Based on defined logic, they provide pass/fail outputs to stop failures at the station, signaling PLCs, robots, MES/QMS systems, and plant dashboards for traceability and compliance.

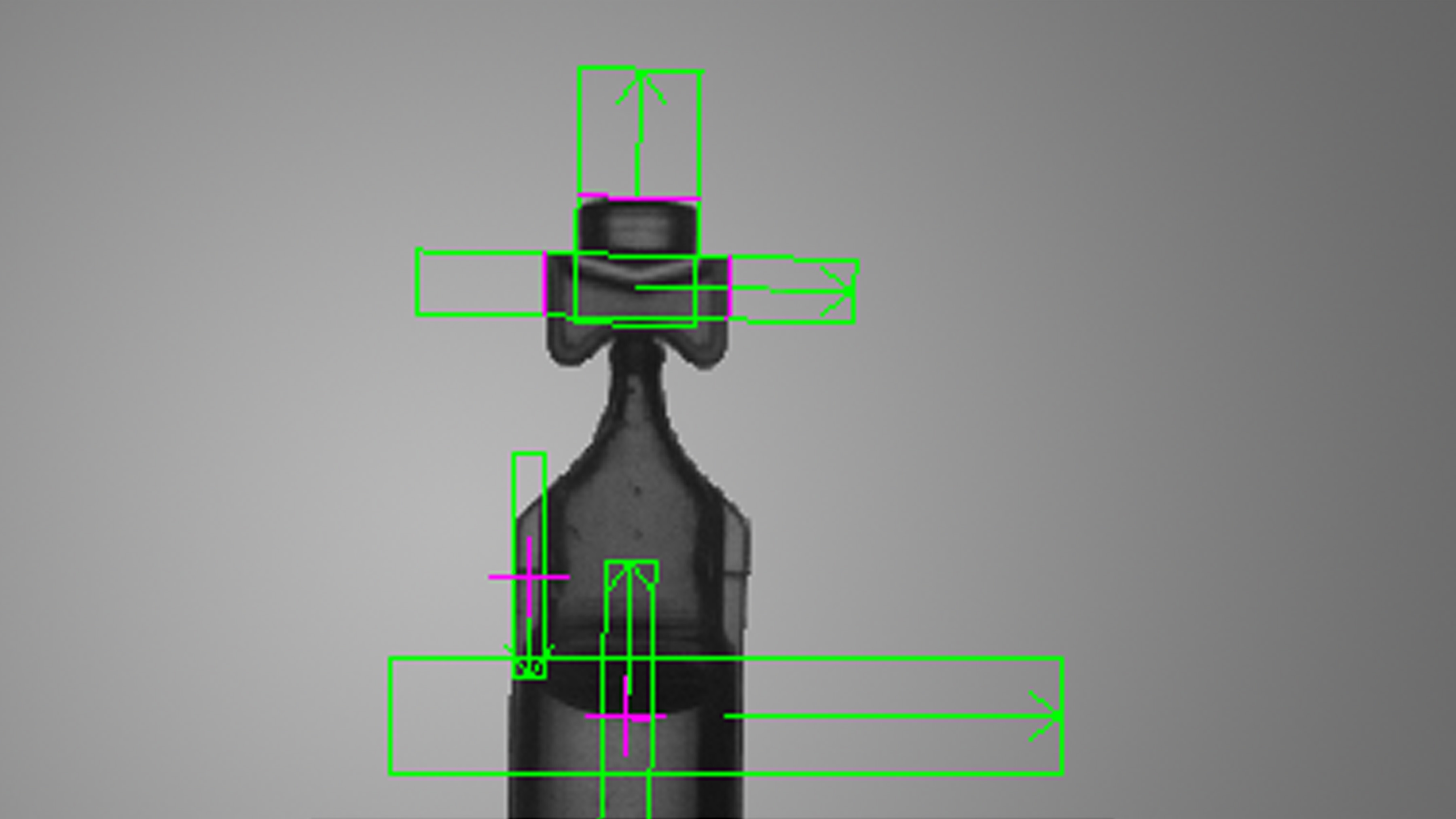

Build and manage inspections

Zebra Design Assistant accelerates deployment and standardization across medical device production lines by providing a flowchart-based environment that allows engineers to configure inspections without coding, utilizing proven rule-based tools for pattern finding, measurement, code reading, OCR/OCV, and presence/absence checks. With drag-and-drop tools, users can achieve fast, explainable pass/fail results with confidence scores, create operator HMIs, alarms, and re-inspection workflows within the same project, and log images, results, timestamps, part/lot IDs, and metadata to MES/QMS systems. Additionally, it supports compliance through effective management of recipes, permissions, and versioned projects.

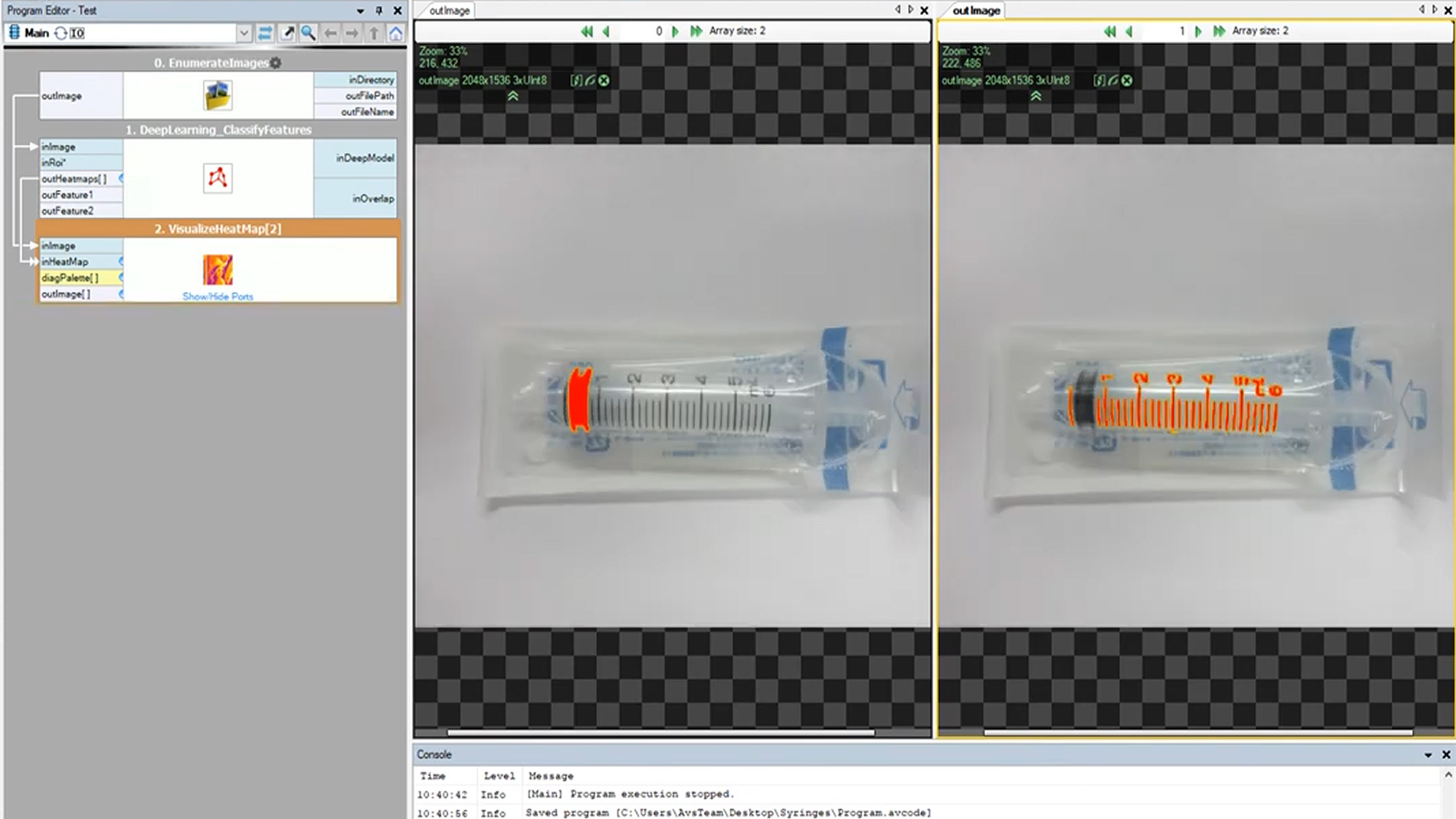

Find the hard defects with deep learning

Zebra Aurora Vision Studio enhances traditional rule-based methods by incorporating deep learning to handle variability and subtlety, enabling it to learn acceptable variations and identify anomalies. Users can train classification, segmentation, or anomaly-detection models using images from their production lines, often with relatively small datasets, and deploy these models alongside rule-based checks to improve detection without impacting cycle time. Zebra Aurora Vision Studio excels at identifying subtle defects such as faint scratches, dents, fibers, inclusions, or surface anomalies that are difficult to code, while providing visualizations like heatmaps, thresholds, and pass/fail outputs with confidence scores. It supports image acquisition from Iris GTX smart cameras and performs inference on edge PCs or servers, allowing for retraining and fine-tuning of models as materials, suppliers, or SKUs change to ensure sustained accuracy.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.