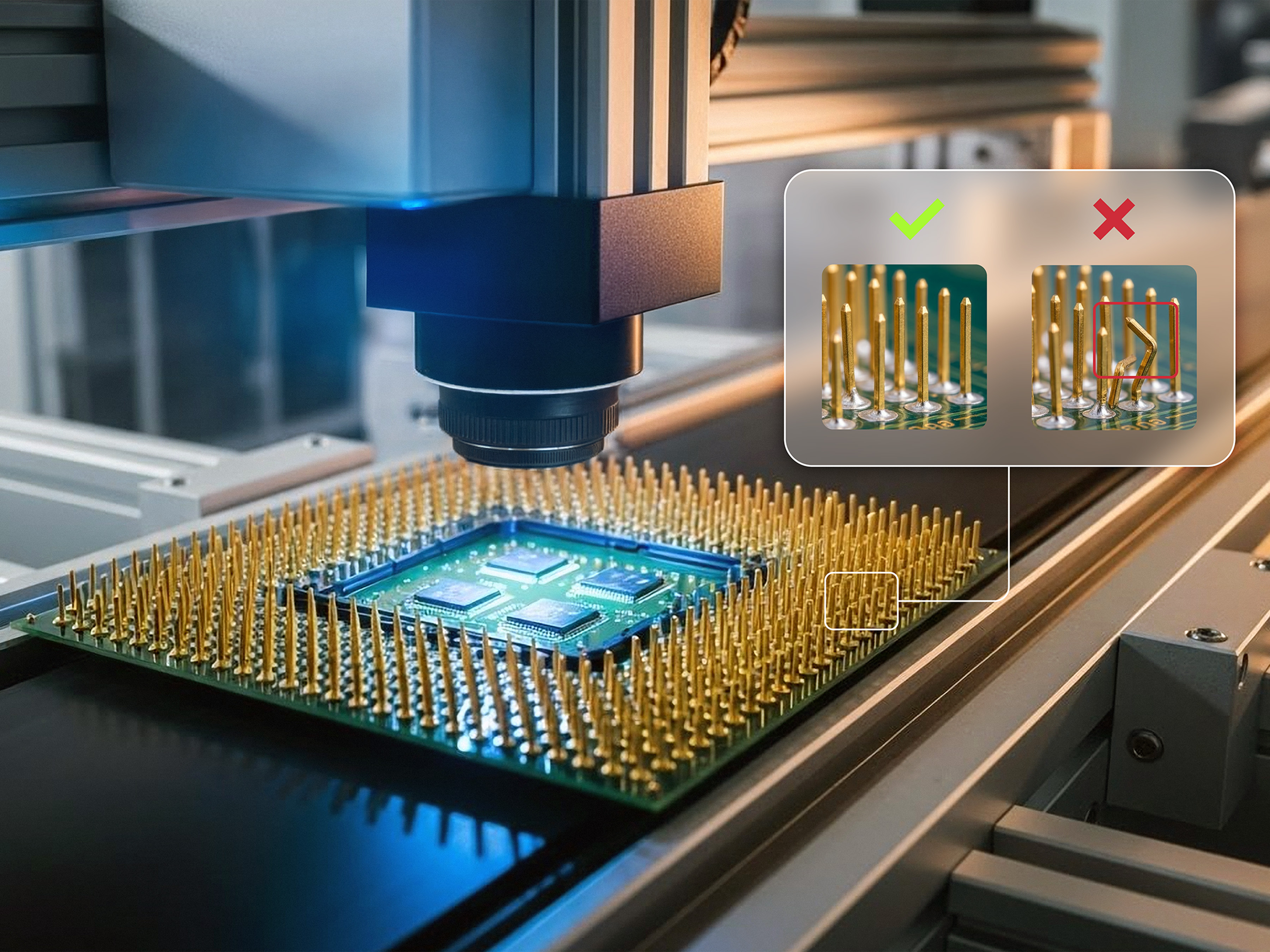

Detect bent leads early with integrated 2D and 3D inspection to increase first-pass yield and stabilize solder quality

Speed 2D inspection for bent-lead detection

At the forming or placement station, an Iris GTX smart camera captures high-speed, high-resolution images of every package to accurately measure the lead position, pitch, and coplanarity from calibrated images. This process helps identify any bent, lifted, or splayed terminals before they reach the soldering stage. The results are shared in real-time with the Programmable Logic Controller (PLC) and line-reject mechanism, ensuring that any nonconforming parts are swiftly removed to maintain smooth and stable throughput.

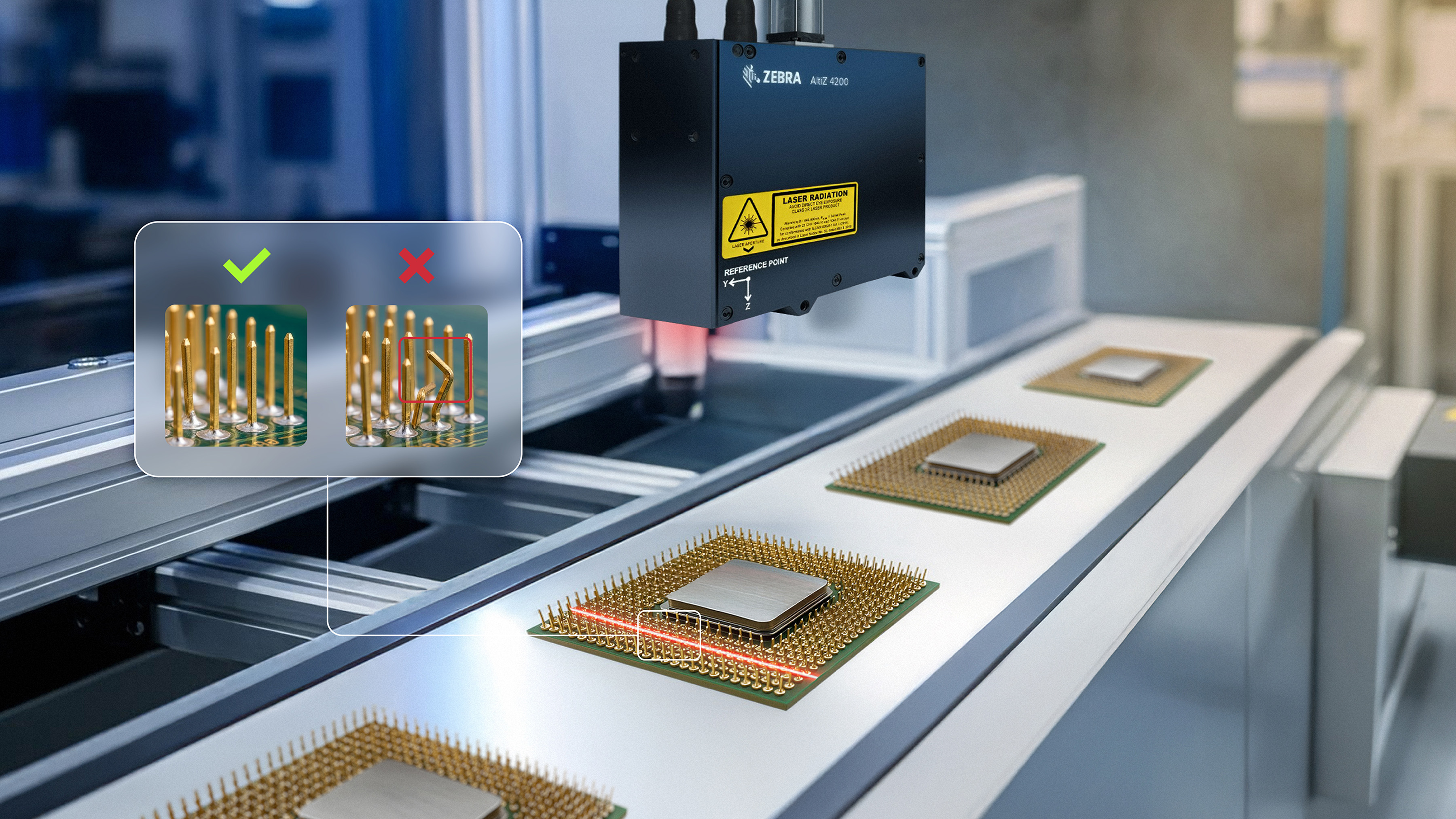

Add 3D profiling to catch tough defects

AltiZ 3D Profile Sensors feature single camera or dual-camera, single-laser designs to capture precise height data without relying on image contrast. 2D measurements can be fused with 3D profiles to confirm coplanarity and lead tip height. This reduces false positives on reflective metal. Results are then communicated to the PLC and reject mechanism, allowing any detected issues to be addressed before reaching the soldering stage.

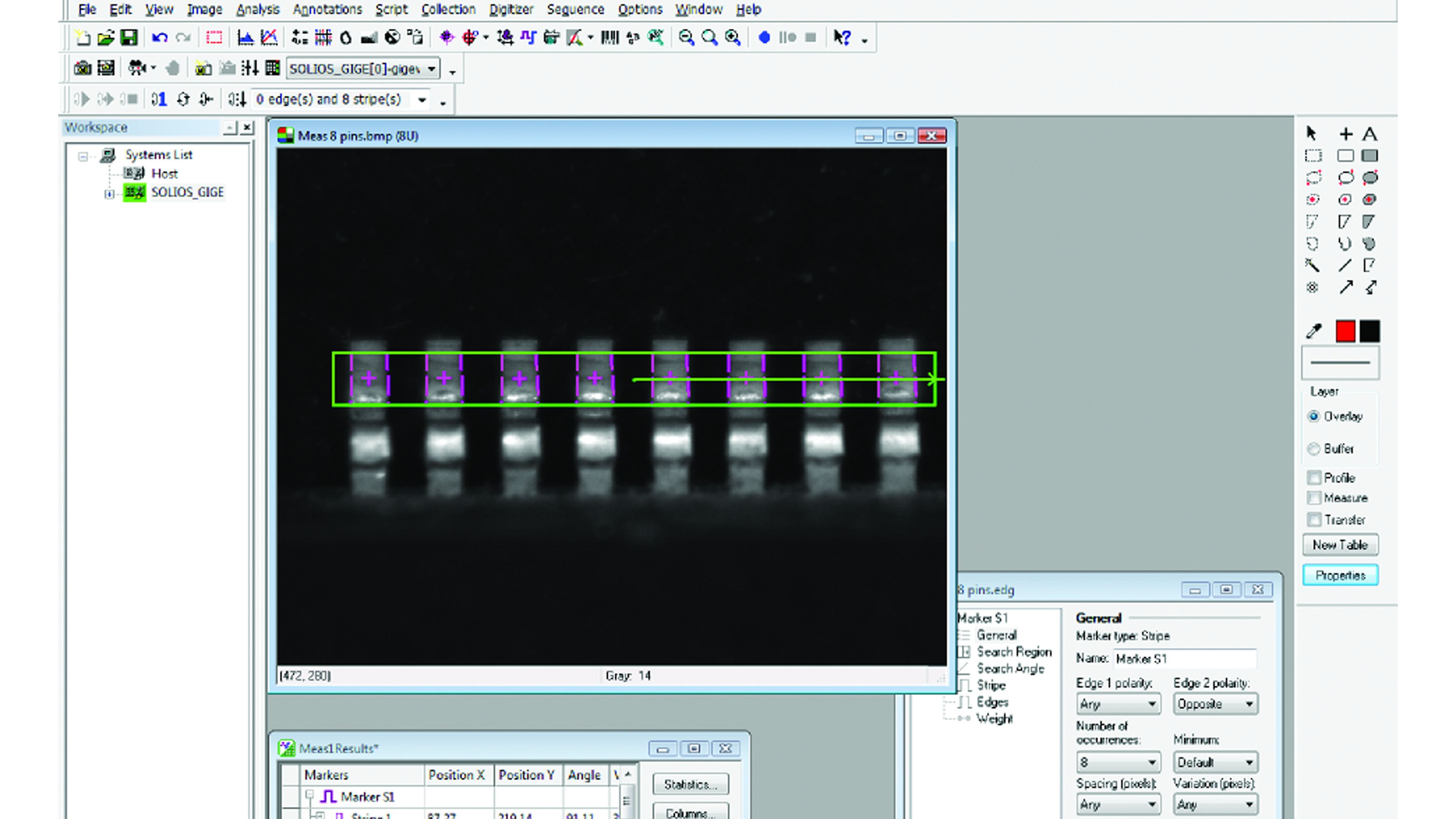

Improve audit trails and error handling

Aurora Imaging Library stores real-time measurement data with lot and device IDs for traceability. Configurable recipes include versioning and change logs for change management. Track first-pass yield and statistical process control trends using control charts and alerts, helping engineers address tooling or process drift before defects accumulate. The system handles errors with automatic retries, manual review routing, or line-stopping, and archives images and results for audit trails. In inspecting bent IC lead terminals, the library ensures precise traceability and accurately identifies bent terminals, while detecting trends for early intervention. Error management and archiving ensure systematic recording and easy retrieval of bent terminal findings.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.