Guide placement and verify assembly with machine vision to speed battery pack build and improve quality

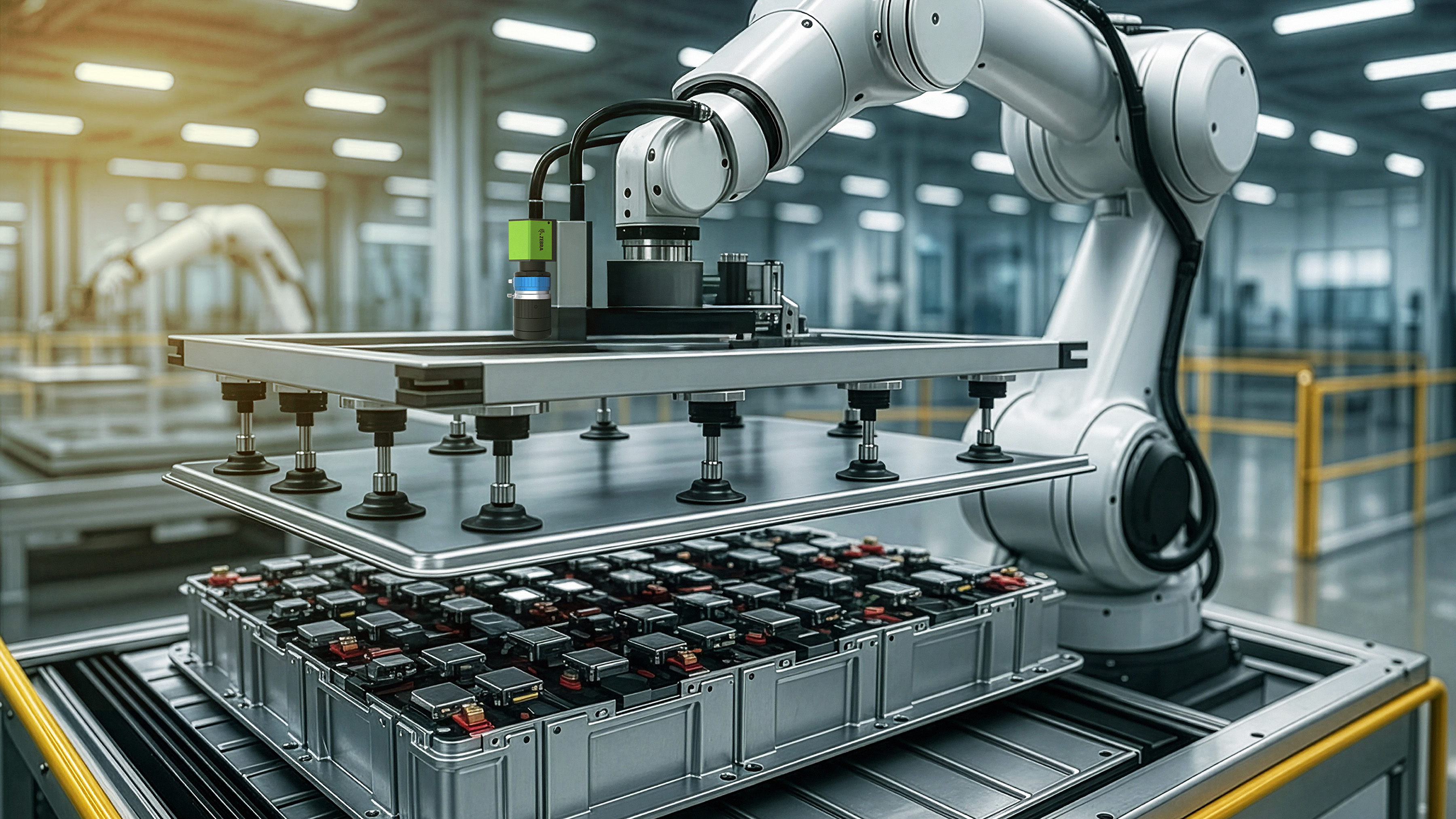

Guide battery module placement with vision

Iris GTX smart cameras capture high-speed images to guide precise module placement, while 2D code-reading and measurement tools locate cases, detect bolt holes, and verify seating before torque. Iris GTX smart cameras provide the resolution and frame rates needed for moving targets, automatically confirming position and fit to reduce manual scans and bottlenecks. Operators receive visual feedback and pass/fail cues, enabling alignment corrections without stopping the line.

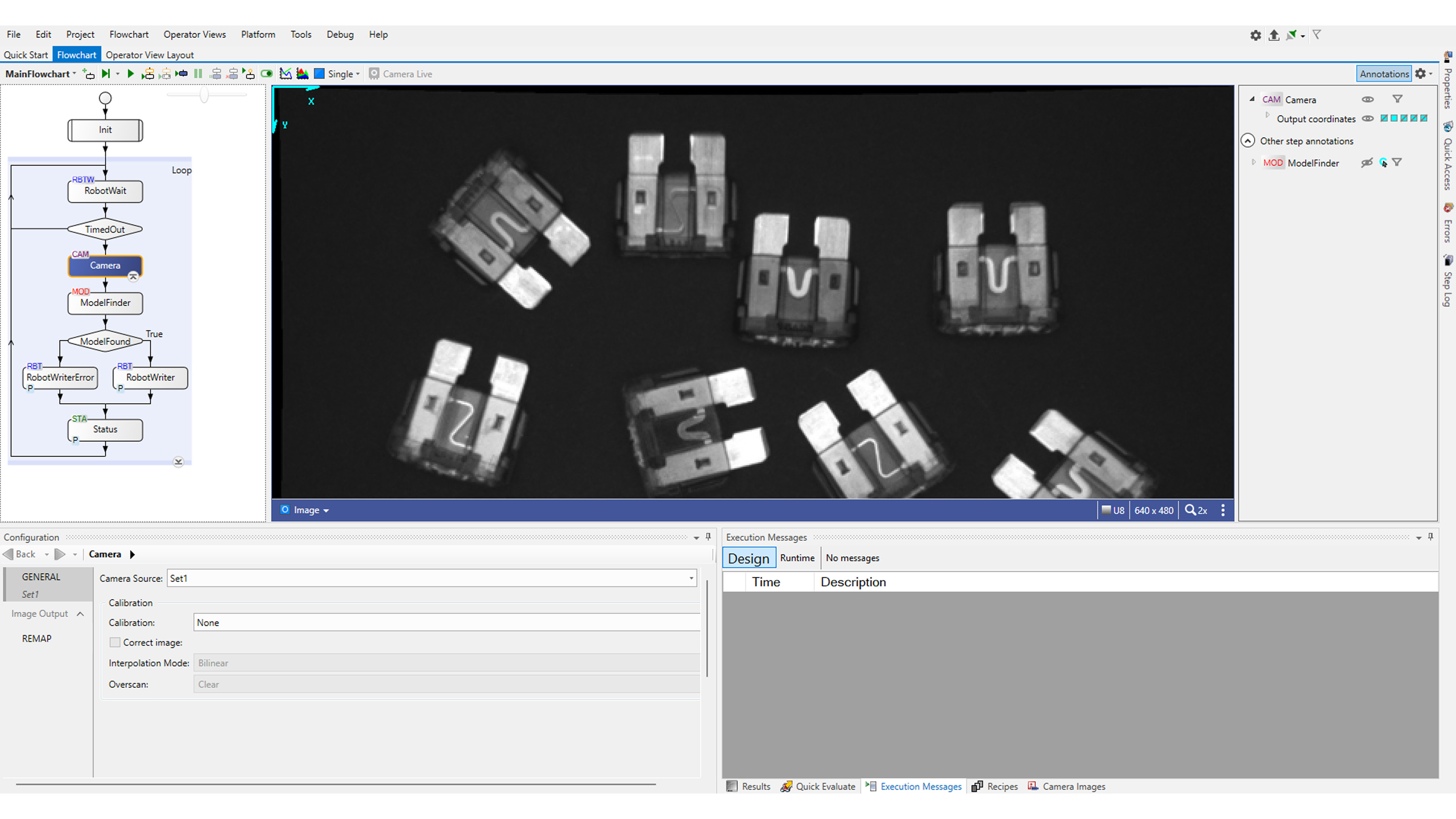

Inspect and verify assemblies in real time

Zebra’s Aurora Design Assistant software provides a flowchart-based environment that enables teams to configure assembly inspection workflows without writing code. It uses a common toolset, including pattern matching, measurement, edge and blob analysis, OCR/OCV, and code reading, to inspect structural integrity, cable clips, electrical connections, coolant fittings, and busbar placement. Results are published in real time to logs and production systems for traceability. Configurable error-handling features, such as retries, alternative checks, and automatic routing to rework, ensure robust inspections under varying conditions.

Improve robot guidance and component inspection

Zebra CV60 cameras play a dual role in robot guidance and quality verification. During assembly, the system ensures precise alignment and adapts to new designs via an intuitive interface. Additionally, the CV60 performs fastener verification by inspecting for the correct type, presence, and proper placement of fasteners, while detecting defects such as damaged threads or improper torque. For cover-to-lid assembly, the CV60 provides advanced guidance and alignment, ensuring proper sealing and environmental protection, while performing pre- and post-assembly inspections for defects.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.