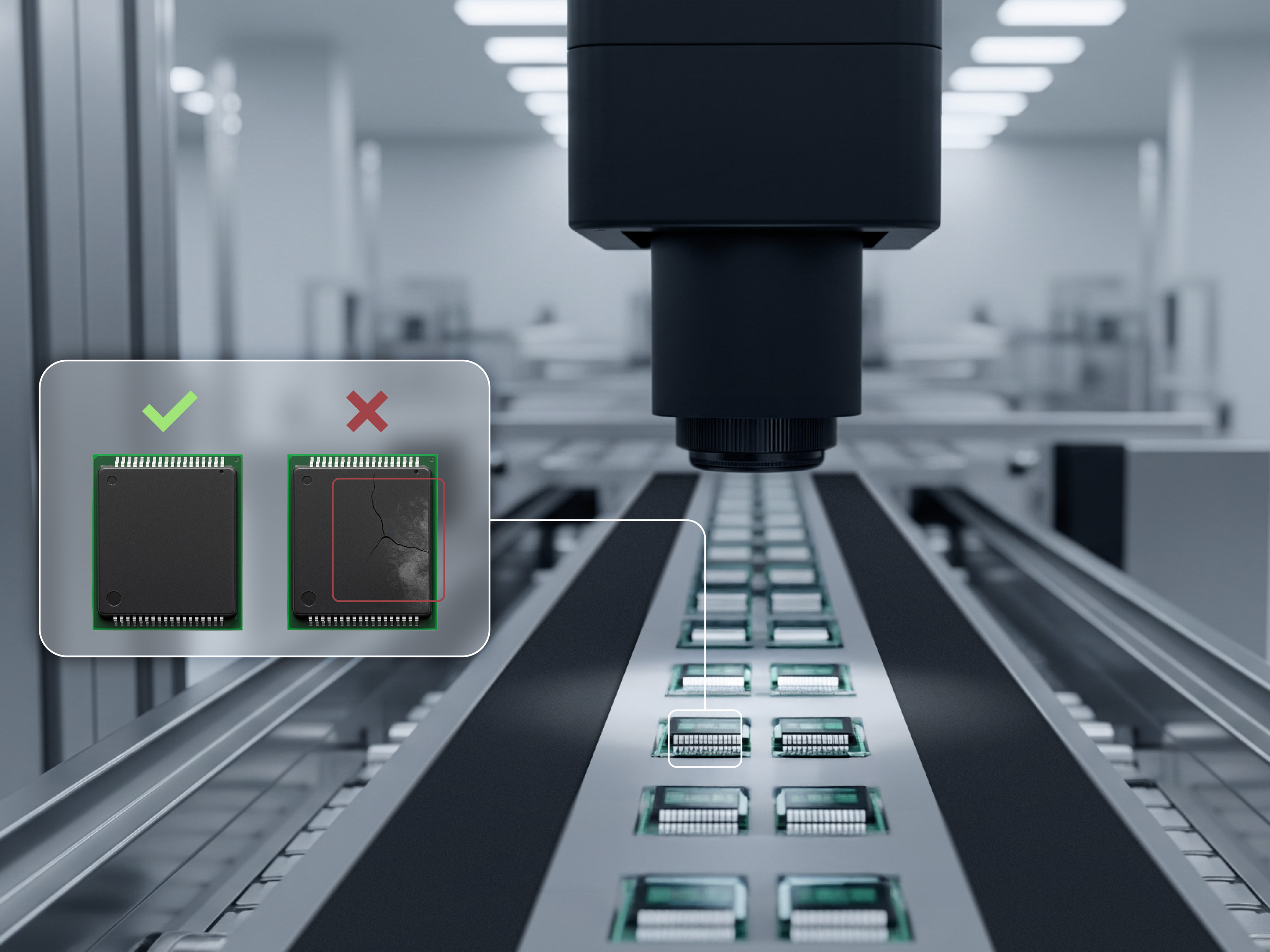

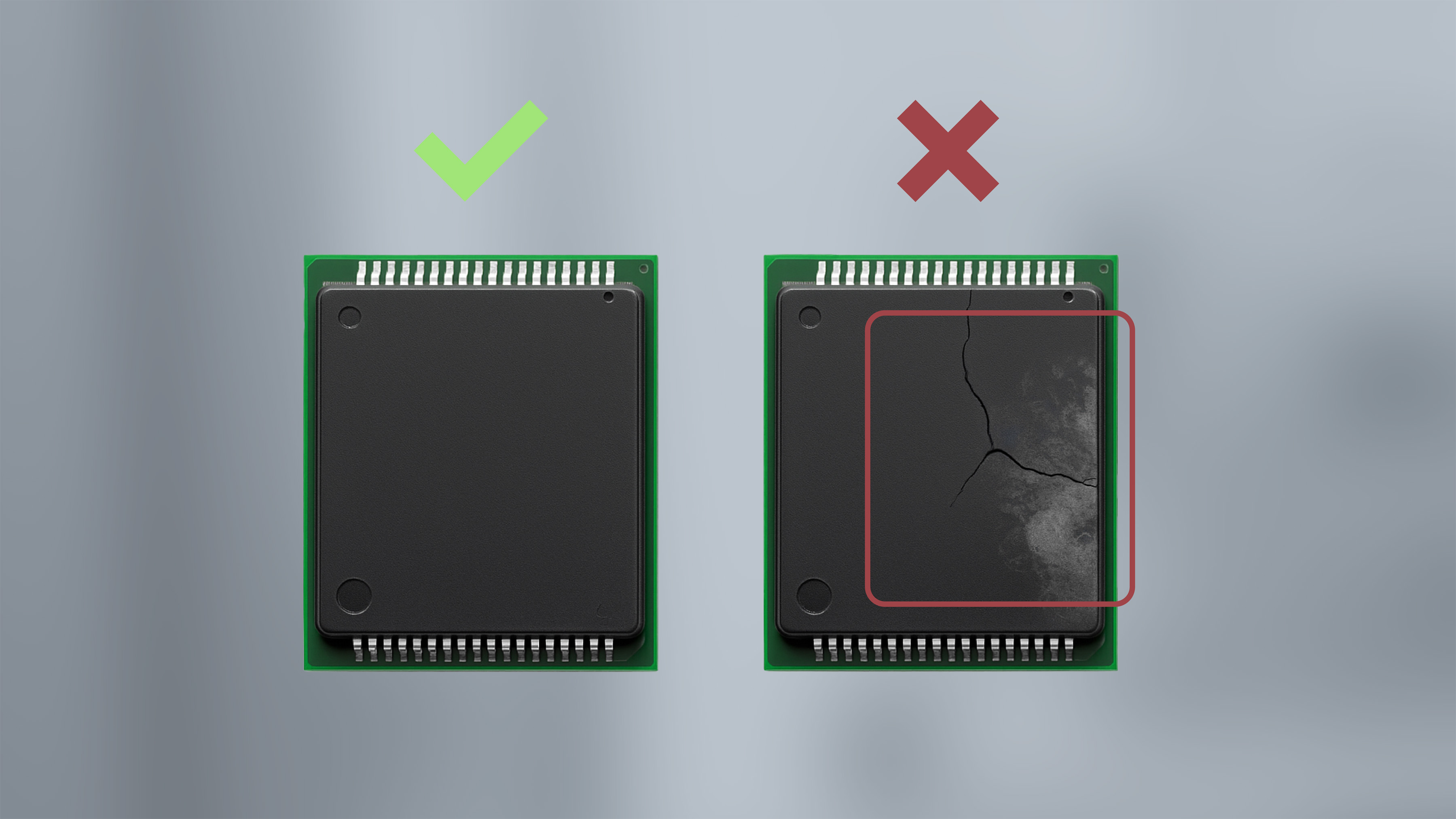

Combine track-and-trace, 2D/3D inspection, and image processing to catch IC defects at full production speed and maintain comprehensive end-to-end records

Accelerate high‑speed image capture

Rapixo frame grabbers support high-speed image capture at high resolution to detect yield-limiting defects in IC components without compromising throughput. Zebra Frame Grabbers support the latest high-bandwidth camera interfaces, including Camera Link, CoaXPress, and CoaXPress-over-Fibre, with generation-to-generation compatibility. Custom image processing algorithms using field-programmable gate arrays (FPGAs) can be ported to new machines, reducing the time and engineering overhead involved in bringing new solutions to market.

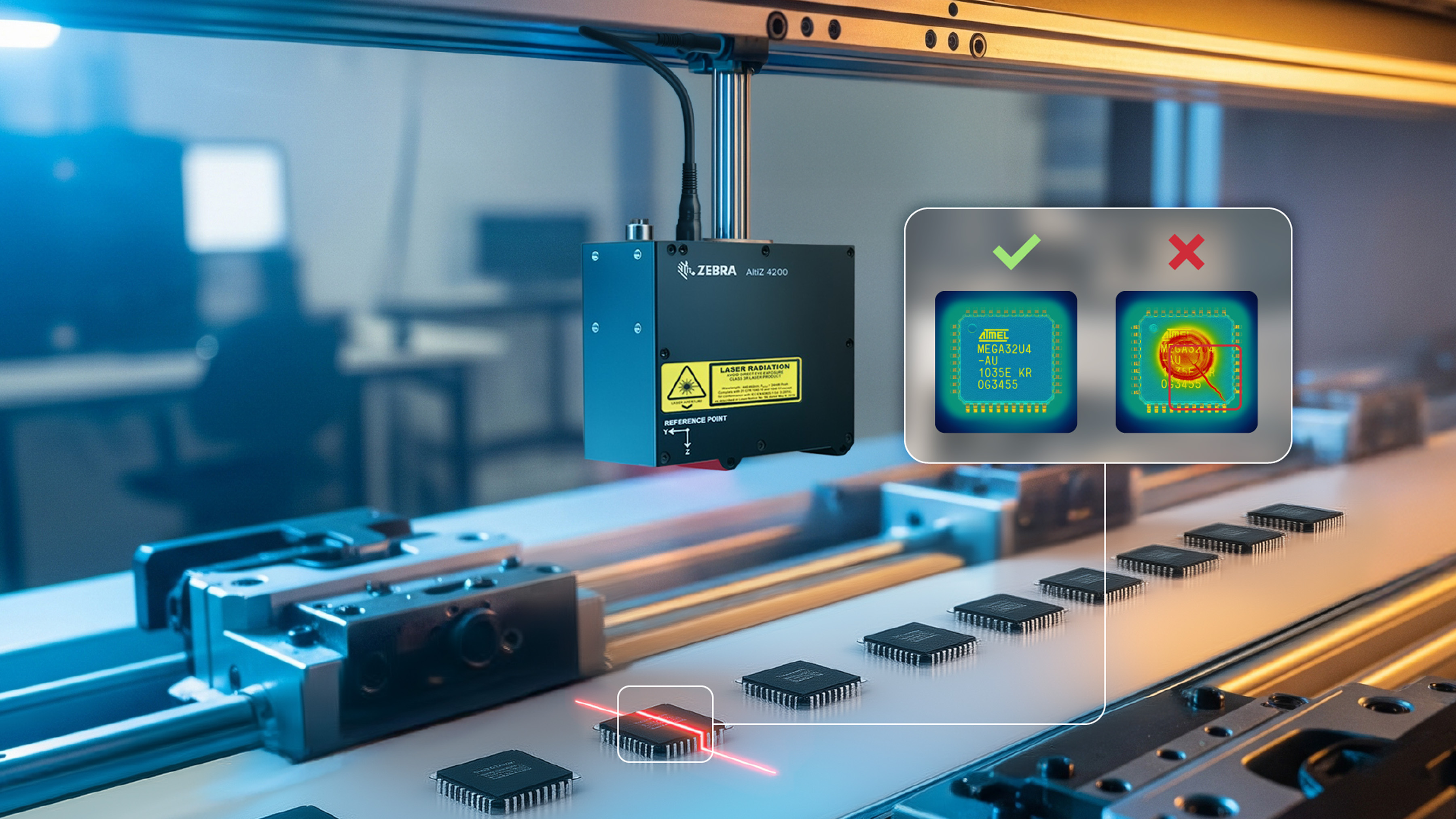

Apply thorough 3D surface and dimension checks

AltiZ 3D profile sensors add calibrated height data revealing minute defects that 2D alone can miss on reflective or low contrast packaging surfaces, such as cracks or molding defects. The AltiZ profile sensor captures precise profiles for coplanarity, standoff, package height, and for determining solder height while maintaining inspection speed.

Drive process improvements in IC manufacturing with data-driven insights

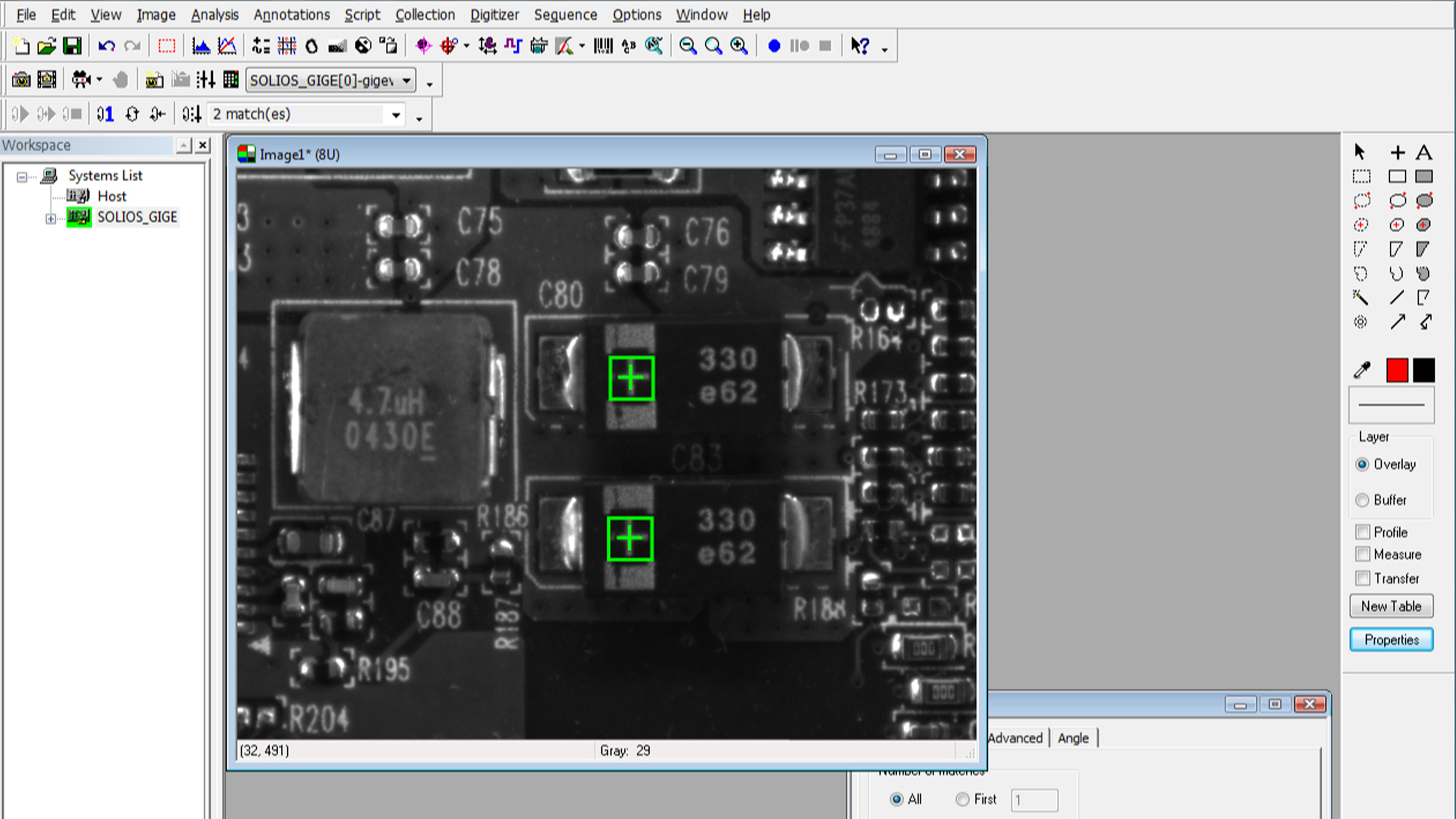

Aurora Imaging Library elevates IC inspections by offering a comprehensive suite of high-speed, high-accuracy vision tools offering code-level customization for automated optical inspection (AOI) applications. These tools facilitate key tasks across multiple stages of IC manufacturing, including locating and orienting ICs using advanced geometric tools, detecting surface defects with image processing and edge detection, and verifying markings through OCR and code reading. The library also provides precise 2D and 3D measurement capabilities, ensuring compliance with strict manufacturing tolerances.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.