Design an in-line vision system for EV battery cell inspection to detect surface flaws, verify electrode alignment, and eliminate foreign objects without slowing throughput

Guide stacking of anodes and cathodes with micron accuracy

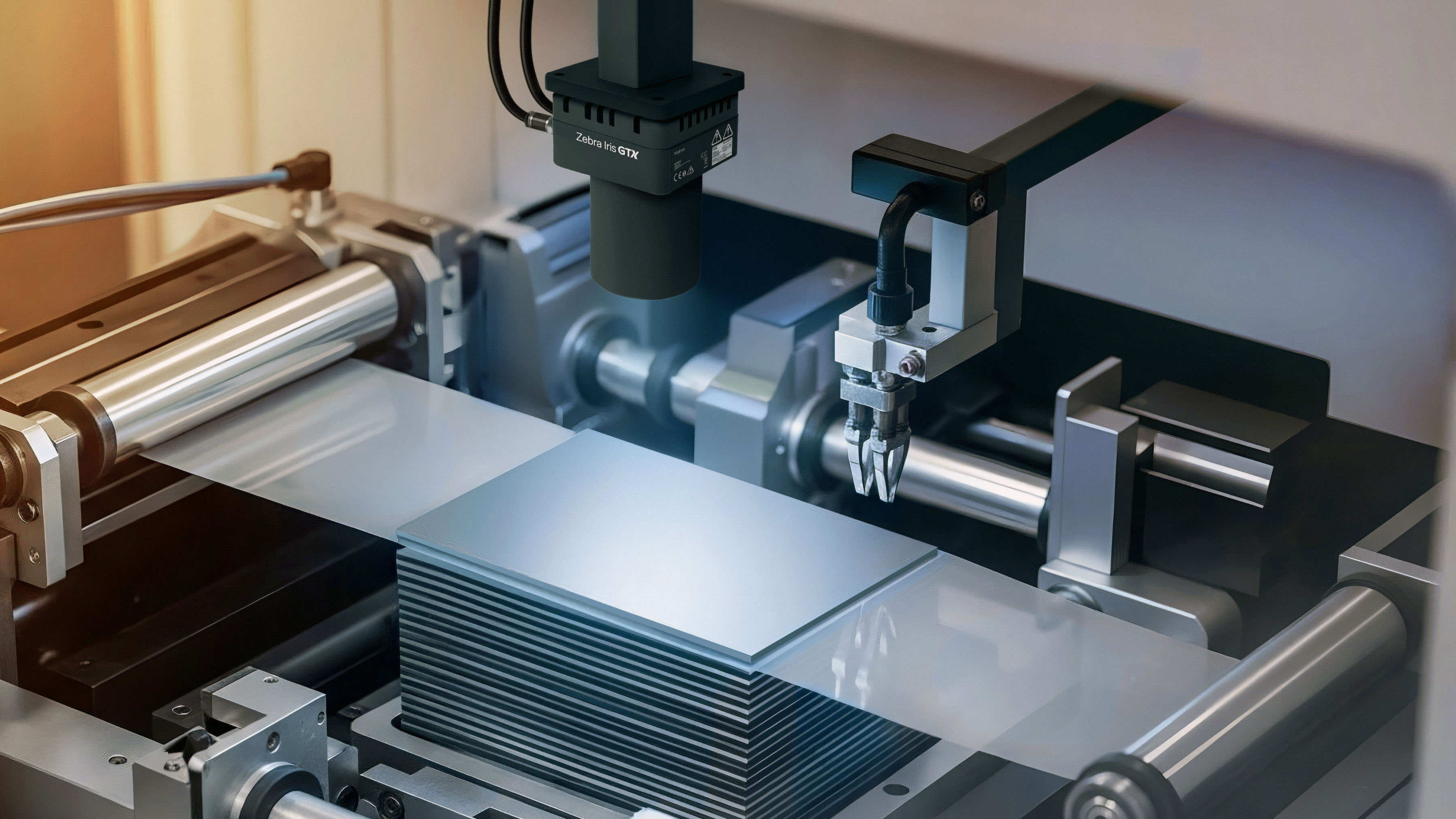

Stack misalignment between anode and cathode layers risks shorts and inconsistent performance. Zebra Iris GTX smart cameras detect fiducials and foil edges, then guide robots to place each layer with an accuracy of near 10 micrometers (µm). Offering up to 16MP resolution with HDR, they resolve challenging surfaces like reflective foils, black coatings, and thin tabs. Integrated lighting control and compact, IP-rated housings simplify deployment in particle-controlled zones. Pass/fail judgements are relayed to the programmable logic controller (PLC) for immediate correction in the form of alarms, automatic retries, and safe stops.

Validate cell components at line speed

Variations in electrode and separator thickness can trigger safety issues, capacity loss, and early failures in battery cells. Vision inspections powered by Zebra Frame Grabbers and Aurora machine vision software checks uniformity and coating coverage in real time using calibrated intensity profiles, pattern matching, and edge-based measurements. With support for the latest camera interfaces and bandwidths, Zebra frame grabbers support high-resolution image capture at the rapid speeds required to meet the demands of electrode production lines.

Eliminate damaged and contaminated cells

Prior to sealing, the housing of completed cells must be inspected for holes, dents, splits, weld defects or debris which might cause shorts or overheating later in the pack. Zebra AltiZ 3D sensors inspect cell casings at full line speed, creating a 3D point cloud of the cell and comparing it against desired thresholds to isolate defective components so that they may be removed from production.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.