Automate final battery cover placement and inspection with vision, 3D sensing, and deep learning to boost yield and keep cycle times short

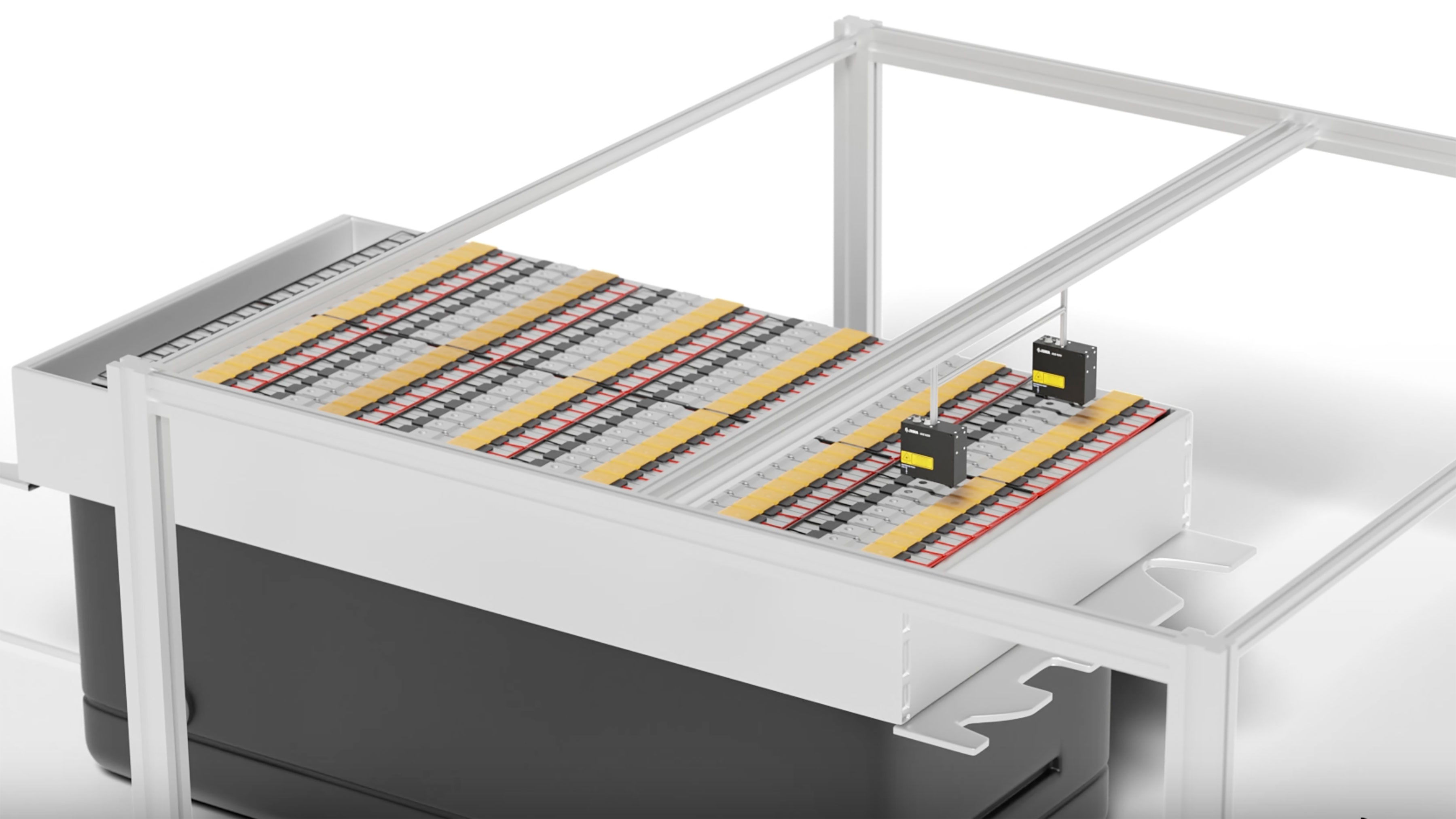

Accelerate final tray inspection

Before the cover meets the tray, the Iris GTX smart camera performs rapid, in-station checks with its built-in 2D tools, including pattern matching, edge finding, measurement, and blob analysis. These features ensure the presence, orientation, and cleanliness of components within tight cycle times. Together, these tools validate assemblies and document results for quality and safety teams. Operators can leverage real-time annotated dashboards to review go/no-go decisions and efficiently monitor workflow performance.

Improve inspection on tough surfaces

Low contrast surfaces, reflective metals, and uneven lighting can hide defects or contaminants. AltiZ 3D profilers use a dual-camera design to minimize scanning gaps and voids. This produces high‑fidelity 3D profiles, depth maps, and point clouds of the battery tray and cover. These 3D results pair with 2D checks to inform joint pass/fail decisions and keep cycle times stable.

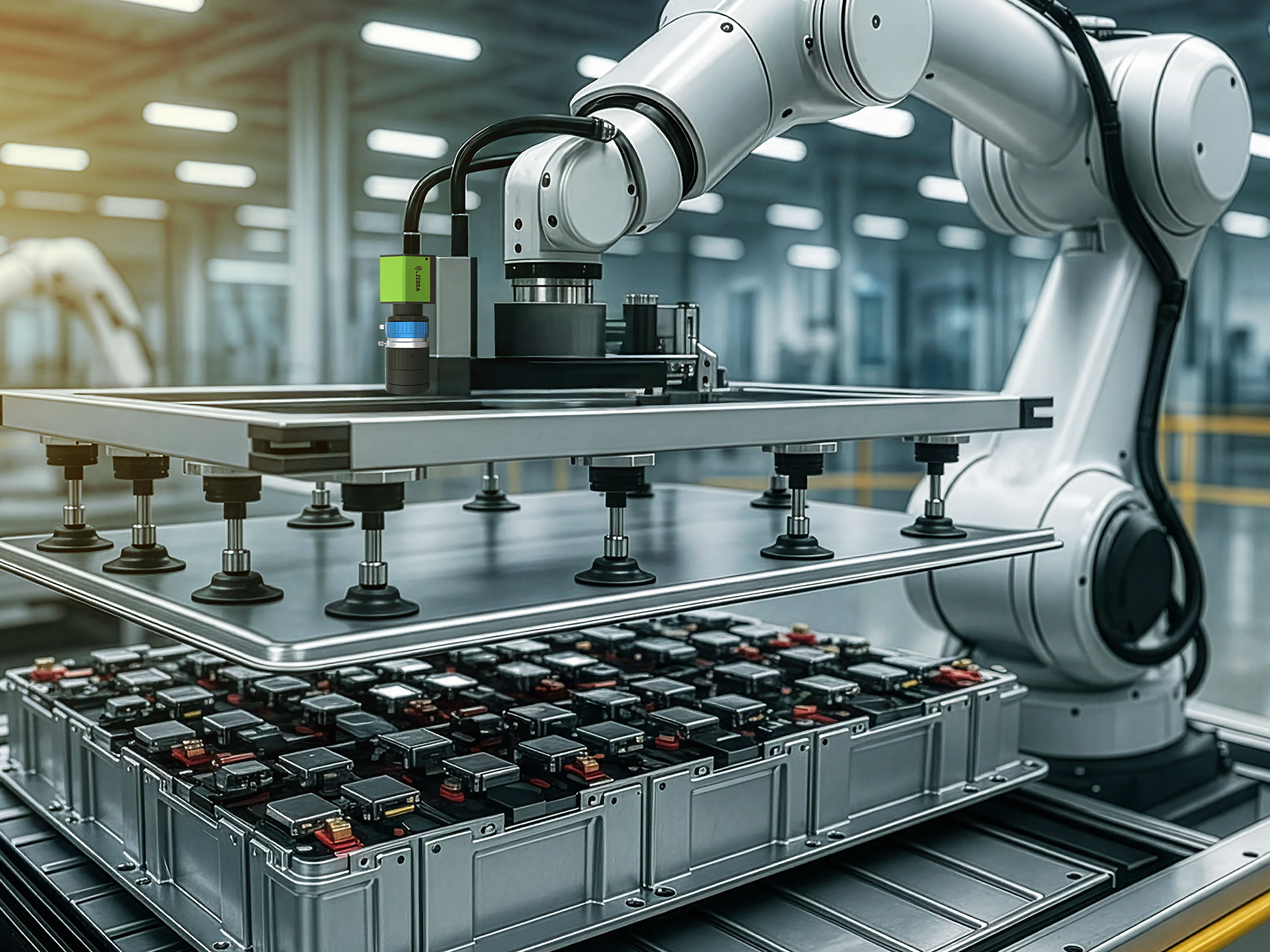

Cover-to-Tray Assembly Verification

After initial inspection and validation, robotic arms precisely position covers and secure fasteners, guided by Iris GTX smart cameras for accuracy. Zebra's Aurora Design Assistant machine vision software integrates guidance, inspection, and pass/fail logic in one interface, using programmed logic to detect problems such as cross-threading and missing screws early. It logs annotated images and results for traceability and faster root-cause analysis.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.