Automate stamping inspection with 2D and 3D vision to detect splits, verify features, and keep automotive body panel production moving

Automate stamped part inspection

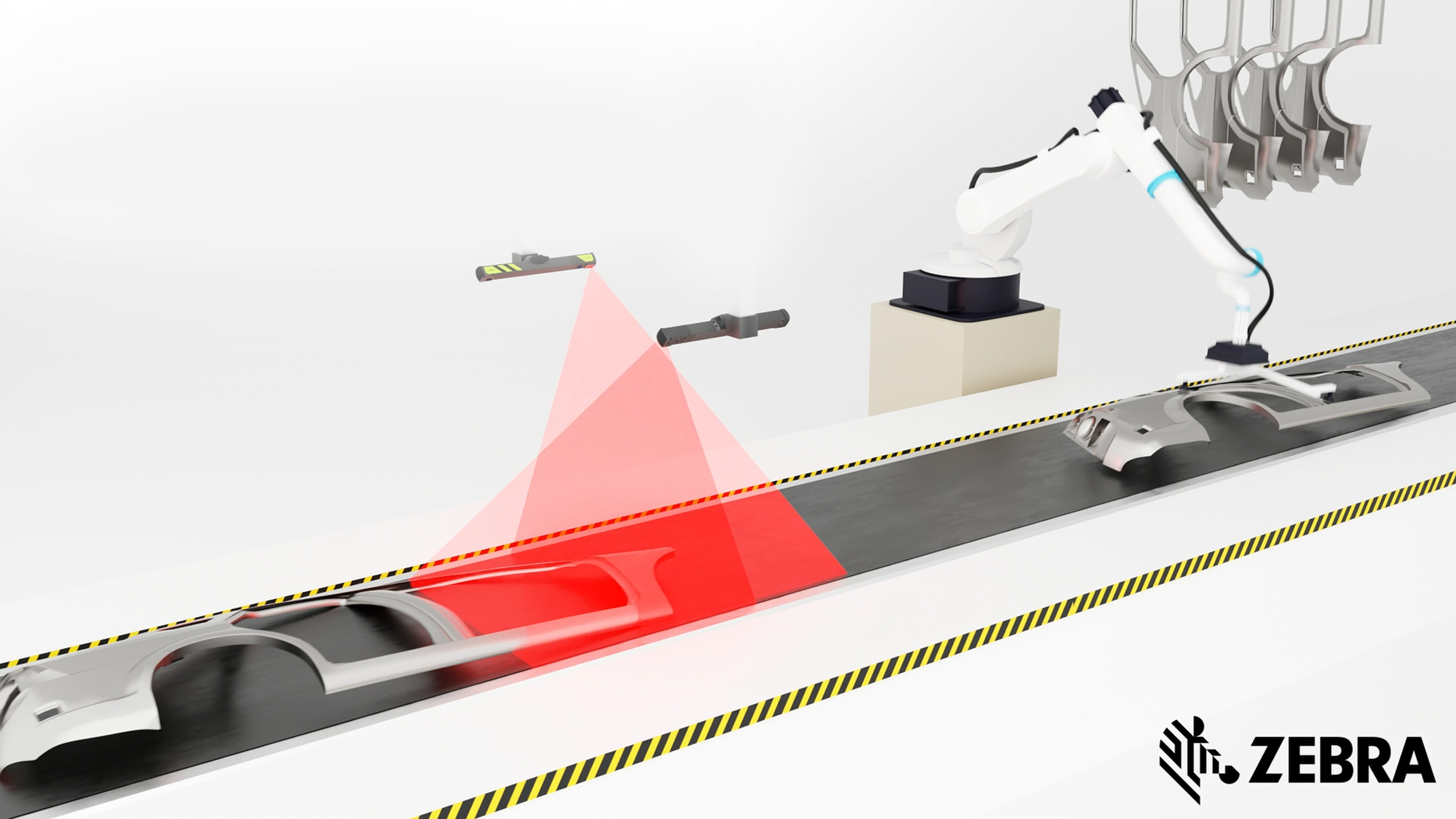

Iris GTX smart cameras inspect panels immediately after the press. The system targets high‑risk zones, such as die‑cut edges, tight bends, and mounting holes, using high‑resolution 2D imaging to detect splits, burrs, surface damage, and out‑of‑position features. Deployed on fixed stations for full‑width coverage, GTX delivers cycle‑time‑matched inspection and consistent results that prevent downstream rework.

Expand to full-surface 3D inspection

Using parallel structured light, 3S Series 3D sensors scan complete body panels on conveyors or robot fixtures in motion. The sensors capture dense topography at production speed, making small dents, waviness, and edge splits stand out even when parts move or vibrate. Results merge with 2D checks from Iris GTX smart cameras, creating a single pass/fail judgment with unified rules and thresholds. This delivers consistent measurement across press stages, simpler changeovers, and fewer false rejects.

Guide robots and close the quality loop

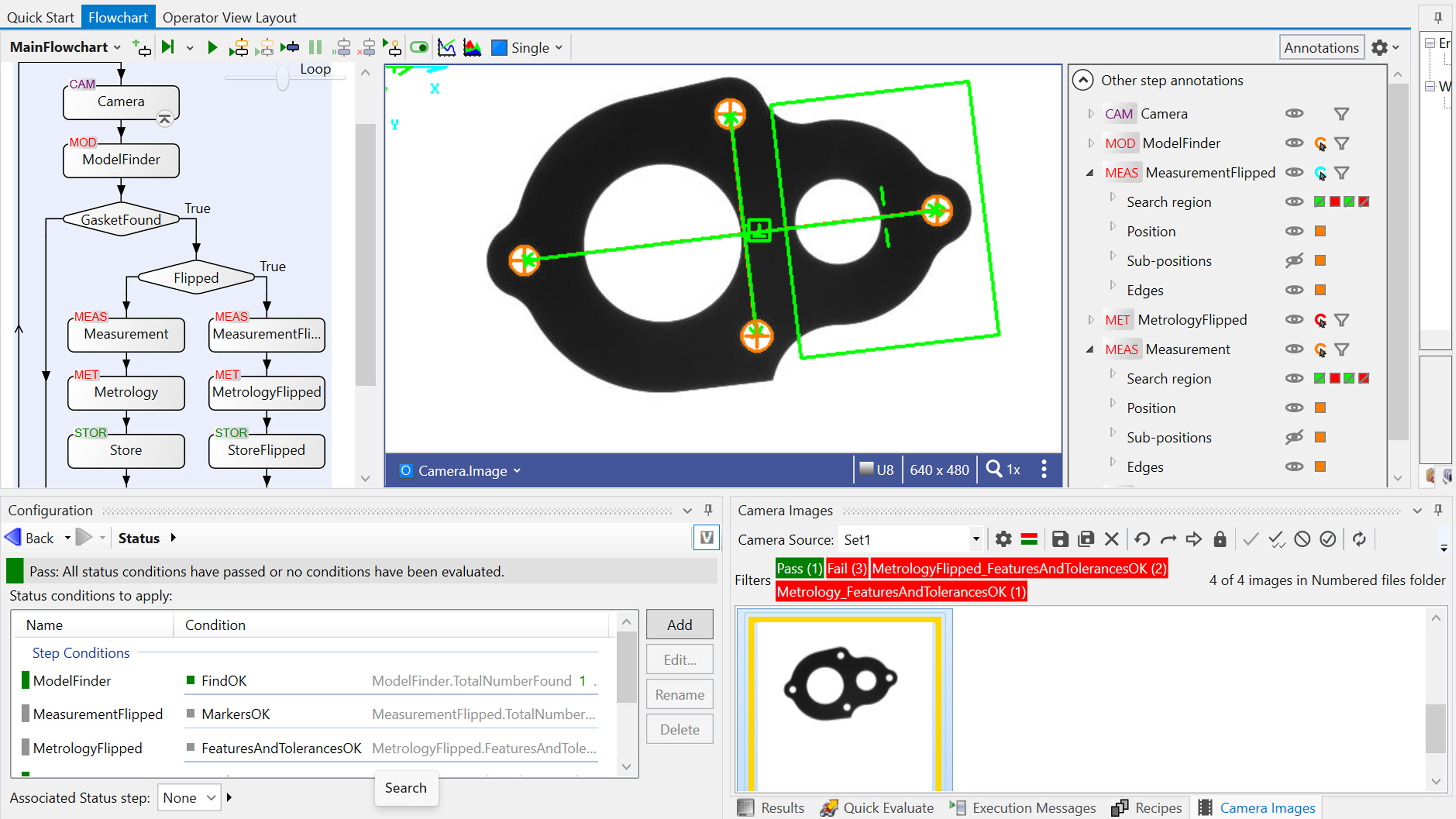

Aurora Design Assistant consolidates inspection logic across 2D and 3D and drives vision‑guided robotics. It adapts to panel variation in real time, coordinates robot moves, and automatically confirms results before release. A single decision engine combines inputs from Iris GTX smart cameras and 3S Series 3D sensors. Images and feature measurements are timestamped for traceability, and results are reported to the Manufacturing Execution System (MES) or programmable logic controller (PLC) to trigger rework or scrap processes.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.