Execute consistent, in‑line verification of die‑cast and machined parts with 2D, 3D, and software‑driven measurement

Leverage 3D inspection for die-cast surfaces and geometry

Use height‑based imaging to detect and quantify surface and dimensional defects end‑to‑end. Zebra 3D sensors scan and create dense 3D point clouds that reveal flashing, porosity, sinks, warpage, and tool wear on raw castings and post‑machining features. Characteristics such as flatness, coplanarity, step height, and true position of product features are calculated with micron‑level precision and compared against desired tolerances. Multiple sensors can be aligned to cover large castings and complex shapes. 3D profiling keeps pace with takt time to improve first‑pass yield whilst ensuring quality to reduce downstream waste.

Standardize inspection

Zebra Aurora Design Assistant offers a flowchart‑based development environment that builds and manages inspections without the need for traditional coding. In addition to application development, Design Assistant allows users to design a web‑based operator HMI for guided use on the line. Aurora Design Assistant is hardware agnostic, enabling consistent deployment across cells and lines. Built‑in utilities like Runtime Monitor, Aurora Profiler, Aurora Capture Works, and Project Change Validator help validate changes, monitor performance, and maintain governed, repeatable execution.

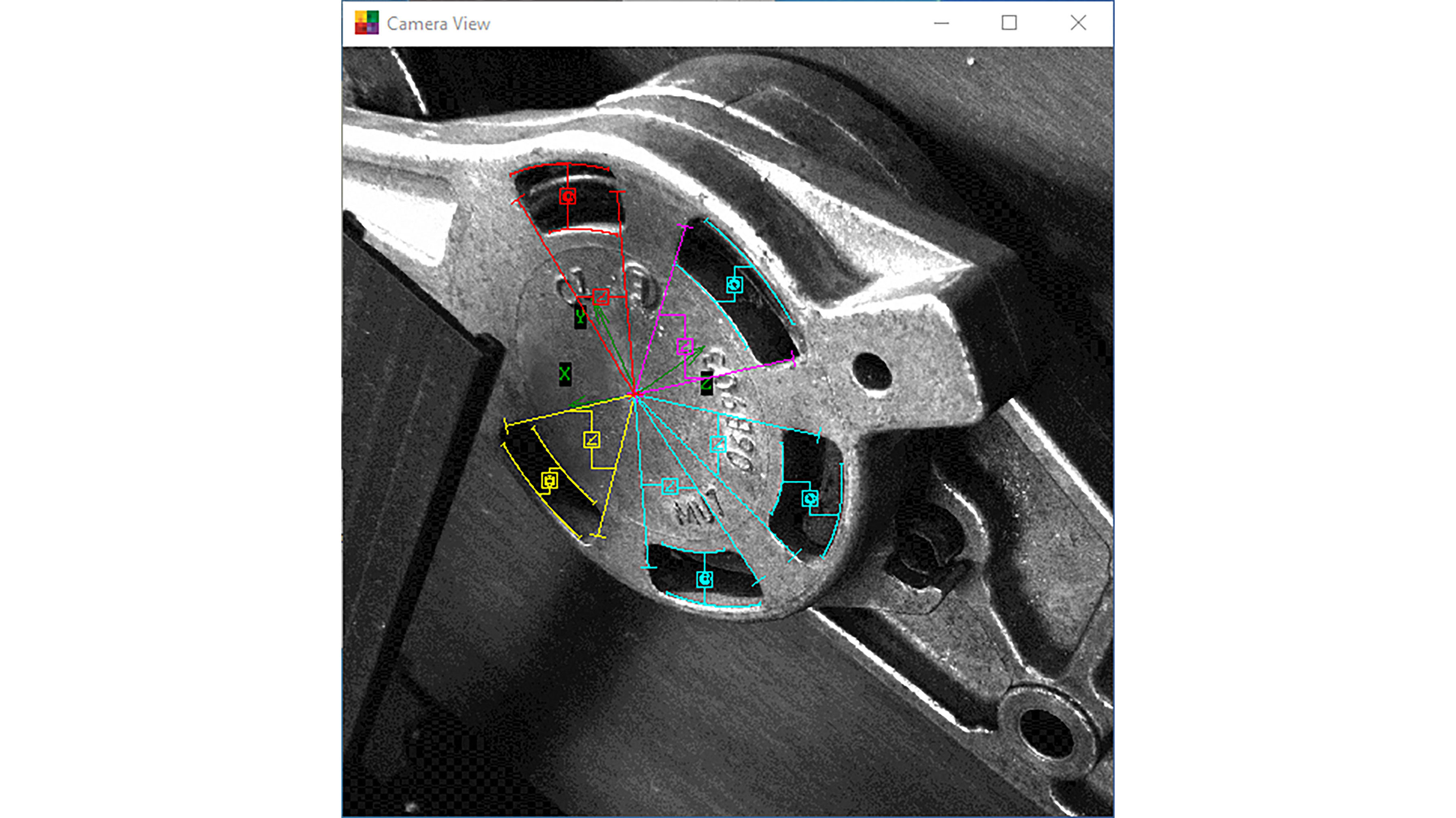

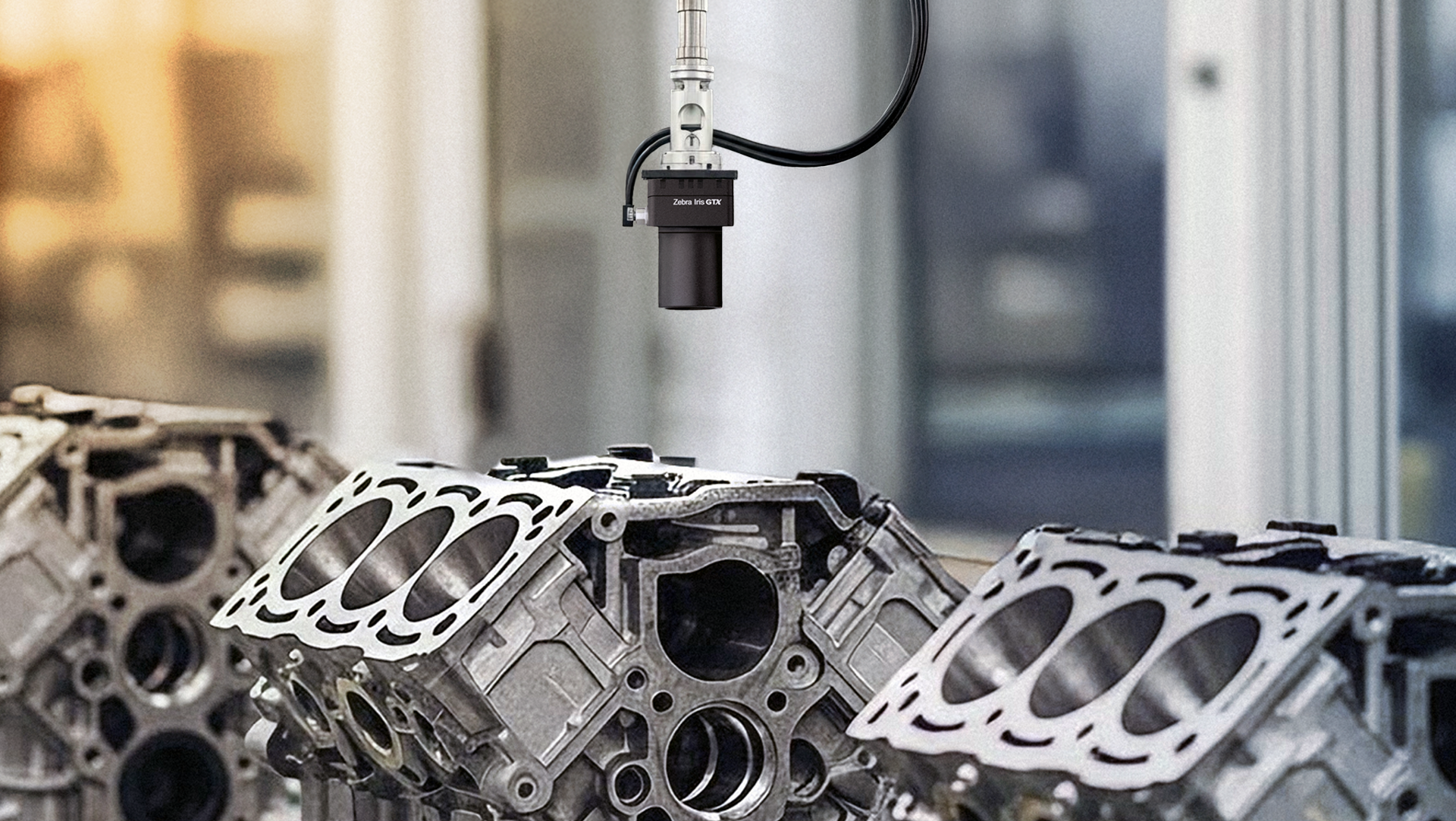

Apply 2D inspection

Validate surface cosmetics, markings, and presence/absence features at line speed with integrated 2D vision. Iris GTX smart cameras combine high‑resolution sensors, onboard processing, and rugged IP‑rated housings to run inspections. The Iris GTX offers a comprehensive range of edge tools, such as pattern matching, edge/contour measurement, blob analysis, and OCR/OCV for DPM codes and engraved text. 2D checks identify pits, scratches, contamination, incomplete deburring, and missing bosses or inserts. They complement 3D measurements to provide comprehensive coverage by verifying identification, orientation, and cosmetic criteria in addition to dimensional checks.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.