Integrate 2D vision, 3D profile sensing, and part verification to detect defects, prevent mix-ups, and document compliance across the line

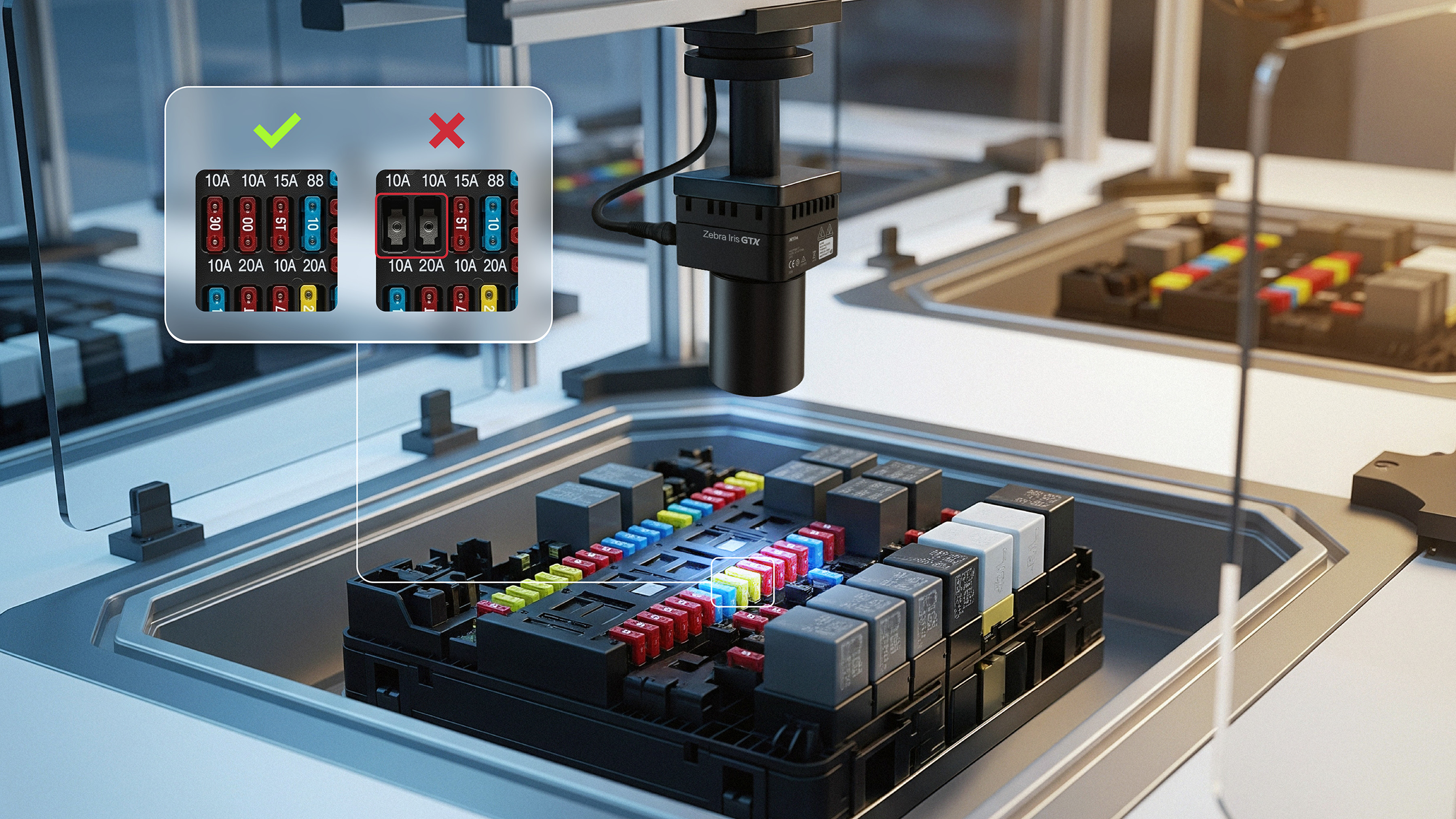

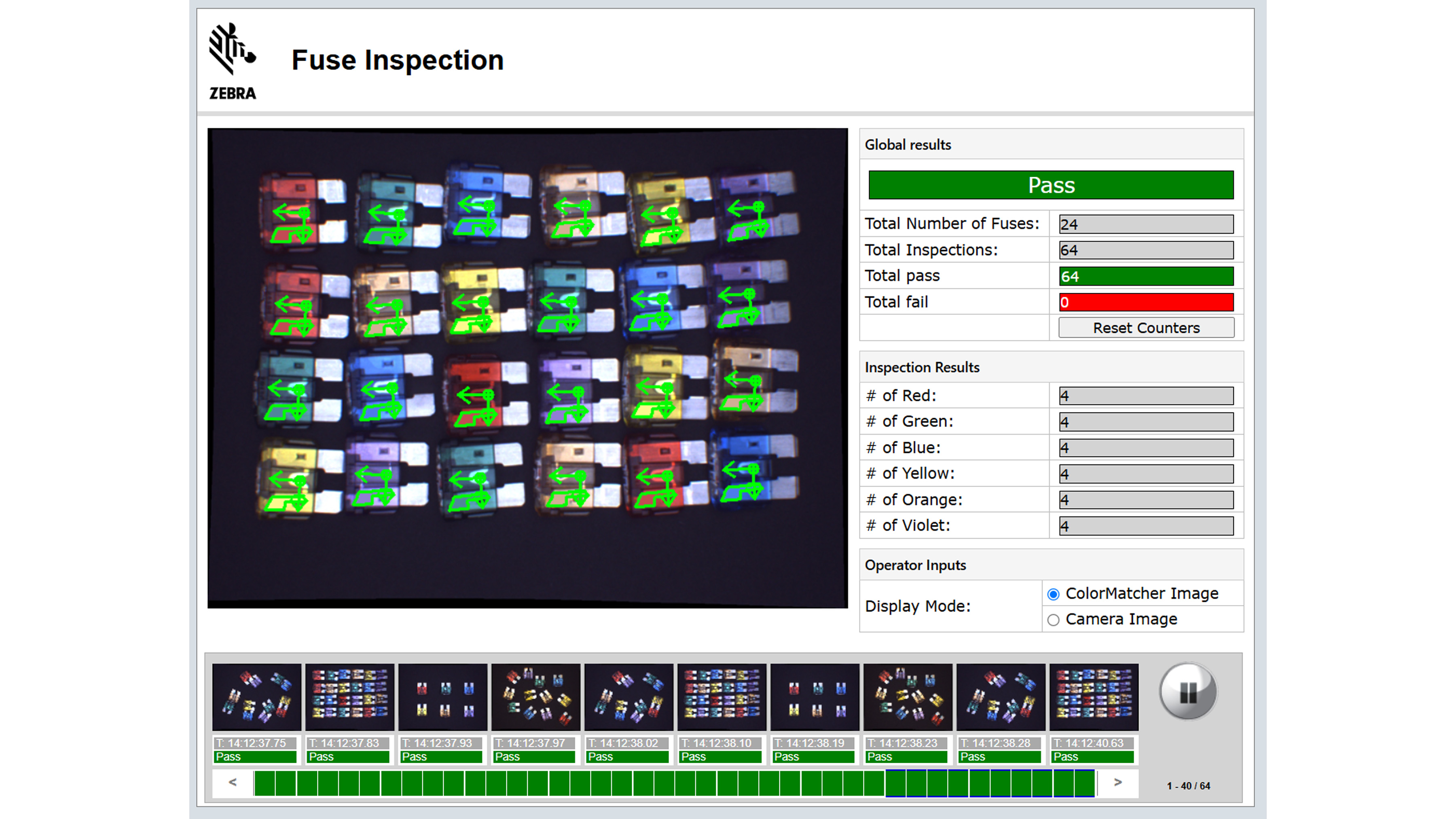

Accelerate 2D inspection with smart cameras

Detect incorrect fuses early with the Iris GTX smart camera. The smart camera is equipped with on-camera processing capabilities, allowing it to analyze the images in real-time to detect assembly defects. High‑speed imaging captures detailed views of end caps, solder joints, and markings to flag missing wires, skewed bodies, or damaged leads. When tolerances are tight, tools for more detailed analysis, including custom classification and optical character recognition (OCR), are used to provide robust pass/fail decisions.

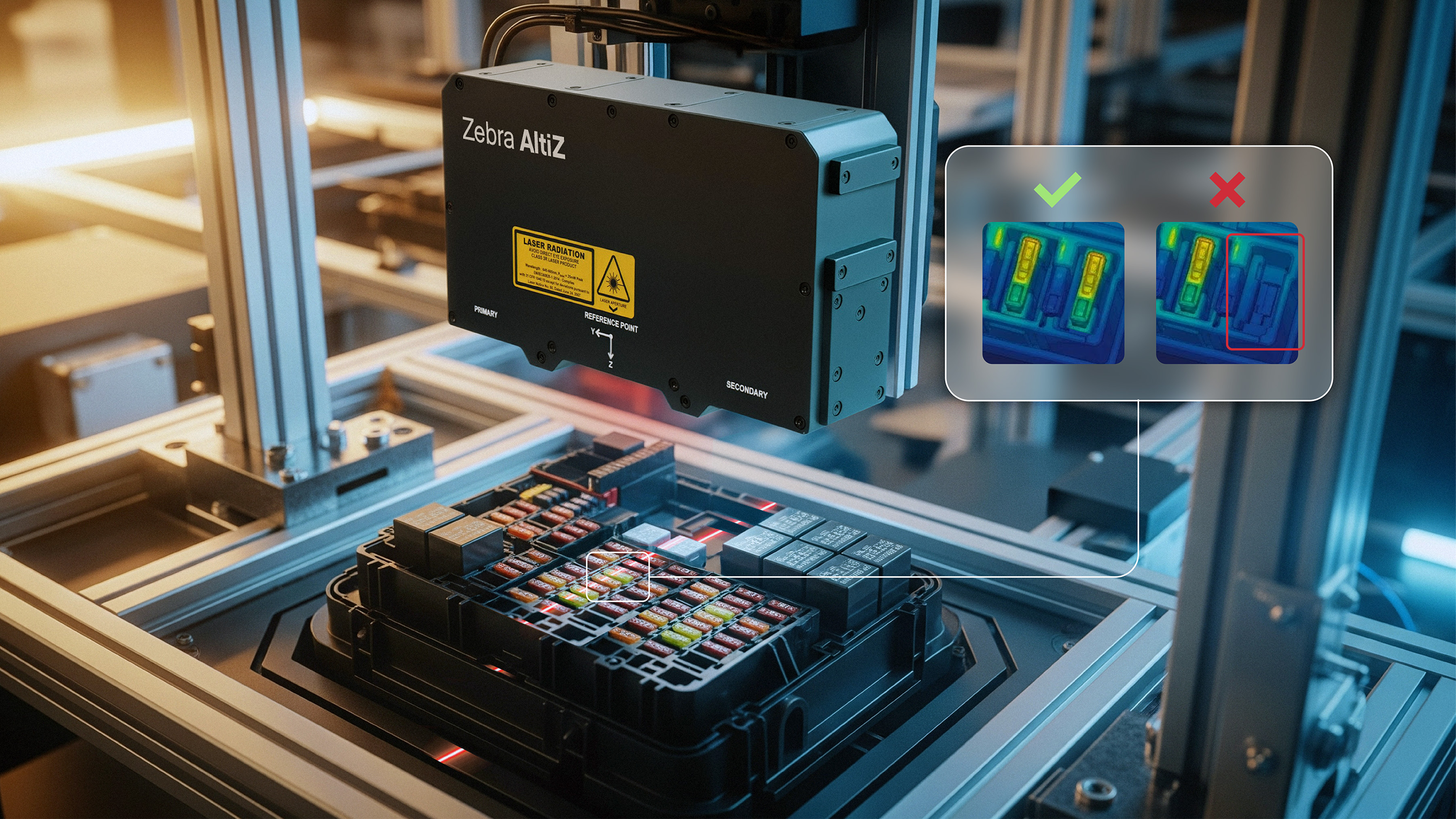

Verify alignment with 3D profile sensing

Confirm fuse alignment and standoff with the AltiZ 3D Profile Sensor. Its multi‑view laser triangulation generates precise height maps that quantify cap height, coplanarity, and seating depth. By generating 3D profiles, the sensor can identify defects or misalignments that might be missed by 2D inspection systems, such as tilted caps or incomplete insertions. This is critical for maintaining the quality and safety of the assembled fuses.

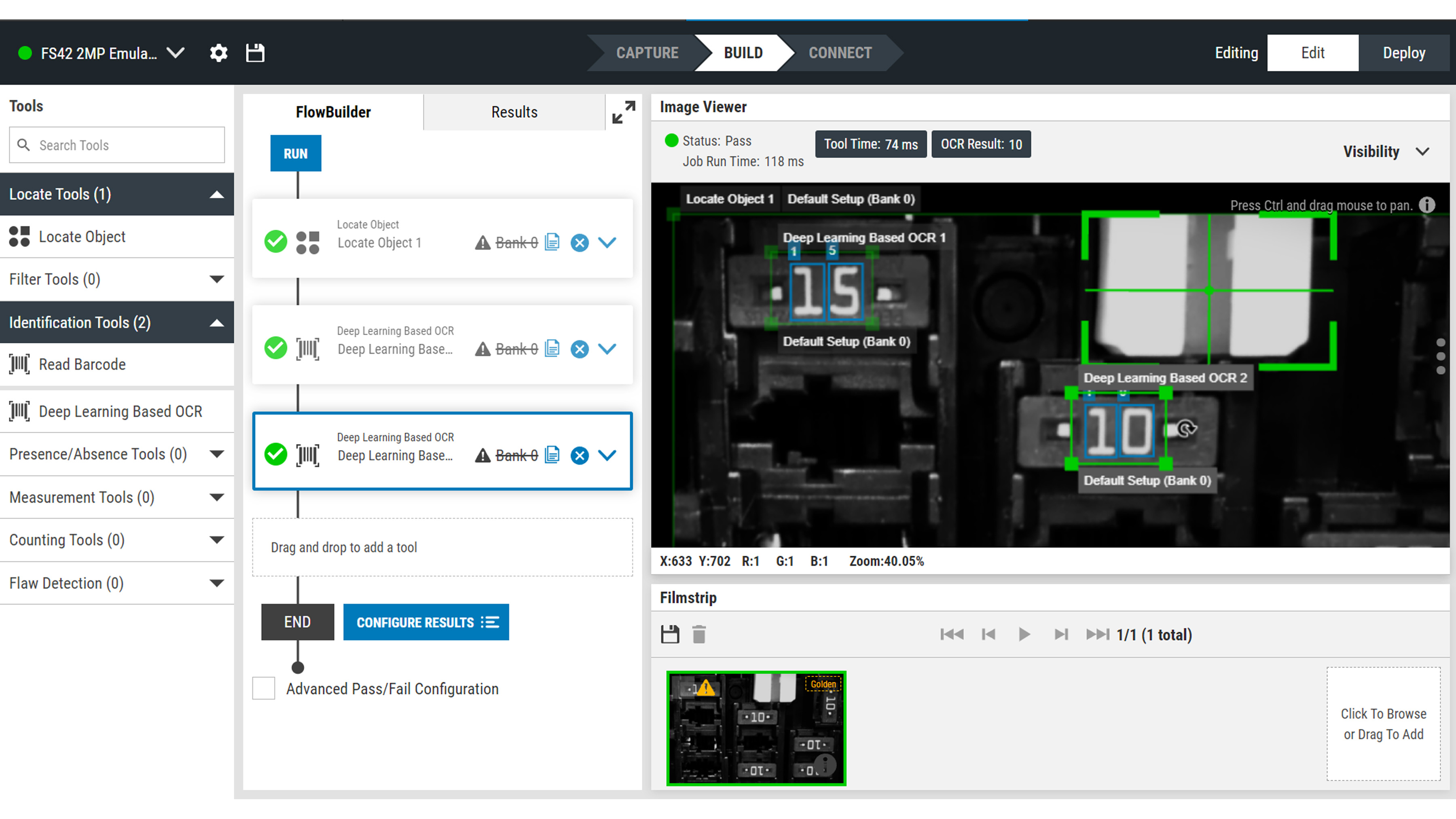

Confirm fuse components with code verification/OCR

Prevent part mix-ups before assembly with Zebra FS Series fixed industrial scanners. These scanners read and validate 1D/2D codes and part numbers on components against work orders, preventing incorrect placements. Aurora Focus software embedded in FS Series scanners includes intuitive setup, a comprehensive range of symbologies, and code-quality grading. It also monitors device health. The software logs scan results and links component details to serial numbers and lot codes. This creates a traceable record from receipt to final assembly and ensures the correct use of components, reducing fuse assembly errors.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.