Researcher-Led Simulation with PacSun Reveals Why Inventory Planning, Store Operations, and e-commerce Fulfillment Problems Can’t Be Solved in Silos

The retailer thought it was struggling to meet e-commerce demand because of poor forecasting. Come to find out, that was only half the story (and issue).

You think you finally have the problem figured out. Your stores are rejecting e-commerce order fulfillment requests because they don’t have the right inventory on hand to fill an entire order. (I mean, you normally wouldn’t stock a store in Florida with a lot of winter coats, right? But once you see more Floridians traveling to wintery wonderlands for the holidays and shopping for coats online before their trips, it’s probably time to reconsider inventory placements.)

So, you call a company like Zebra – and the antuit.ai team specifically – to help you improve demand forecasting and inventory planning based on several different factors, such as travel patterns, weather patterns, events and more. With some AI analysis and recommended adjustments, you start to get the right products to the right stores, at the right time, so they’re stocked to match actual (versus assumed) customer demand. Finally, they can fulfill complete e-commerce orders in a single shipment, and you can stop absorbing the rising costs of split shipments and zone hopping!

But wait…something’s not quite right. Stores seemed to be stocked appropriately according to consumer shopping behaviors. So, why are they still splitting or downright rejecting online orders? Is the inventory going missing? Are associates just too busy to fulfill online orders because of heavy in-store traffic? Is there even really a way to answer these questions? If people say the items aren’t available in store, you should trust them, right?

It’s a frustrating dilemma, and one that’s unfortunately all too common. But just because it is normal doesn’t mean it’s acceptable.

That’s why we have been working with PacSun leaders since the Fall of 2020 to get to the real root of their e-commerce fulfillment challenges and have since started working with other apparel retailers to investigate similar experiences. Here’s what we’ve learned…

Zone hopping and split shipments CAN be avoided when fulfilling e-commerce orders for seasonal merchandise from brick-and-mortar shelves. You just need to monitor the right influential factors for each zip code instead of presuming that people in the South don’t want winter coats or people in the North don’t want bathing suits in December.

Never assume that mismatches between inventory system quantities and actual on-hand quantities are the cause of order rejections – or that rejected orders are the result of confirmed out-of-stocks. Sometimes, order rejections and split shipments have nothing to do with inventory availability.

You can (somewhat easily) put systems in place in the back end and on the store floor to ensure there are no excuses for incomplete or rejected orders. This includes AI algorithms that can increase demand forecasting and inventory placement accuracy across all stores to support omnichannel sales, as well as RFID technology that can hold store associates accountable for on-hand inventory and reduce rejections due to out-of-stock claims.

Now, let me share a bit about how we came to these conclusions, with the help of PacSun and academic researchers.

Shining a Light on PacSun’s Store-Born Online Fulfillment Issues

Going into the first holiday season of the pandemic, with their e-commerce business already booming, PacSun leaders knew that brick-and-mortar stores would have to do a significant amount of e-commerce fulfillment. So, they came to antuit.ai (which is now part of Zebra) to help them improve their inventory placement.

The goal was to get the store closest to each e-commerce customer stocked with the right SKUs, sizes and quantities to be able to fulfill online orders as close to the customer as possible They were getting killed on the rising costs of split shipments and zone hopping, like many retailers thrust into this wild world of omnichannel commerce overnight. So, we helped them in two ways:

We developed an AI-powered demand model that now allows them to look at sales by zip code and by transaction channel. With this model, the PacSun team can now distinguish between the needs of people walking into a store versus the needs of people within a certain radius from that store who are likely to shop online. This combined demand data is sent to their allocation engine which subsequently helps the PacSun team stock each store adequately based on the geolocated shopping patterns of both in-store and online customers. Stores are better positioned to support all sales within their local area, which takes care of the zone hopping problem and likely helps customers get their orders faster.

We made some adjustments to their Distributed Order Management (DOM) system to prioritize online order routing to the stores with the greatest potential markdown liability for on-hand inventory. For example, winter coats are likely to fly off the shelf in New York or Boston because people need coats for months on end up there. But in-store coat sales are sporadic at best in Atlanta or Orlando given the typically warmer winter climate. Because we have demand data for each SKU and store, the AI algorithm we built in this second step is now able to predict which stores are over-inventoried and more likely to take markdowns that hurt margin. In turn, certain e-commerce orders can be pushed to those stores for fulfillment. Of course, we also had to factor in our other objectives of eliminating split shipments and zone hopping, and we did. The algorithm considers distance to customer and the ability to ship an order complete in a single package. So, this second step ended up helping with both e-commerce and in-store margins.

As you can imagine, everyone was starting to feel good. We had solved for two of PacSun’s biggest e-commerce financial drains – or so we thought.

After running the algorithms and analyzing the DOM data a few months later, we realized that about 30% of the online orders that PacSun was pushing to brick-and-mortar stores for fulfillment were getting rejected by the assigned stores. What was especially odd was that not all stores were rejecting orders at the same rate, so there was clearly something going on at the store level, and possibly several different things. We started hypothesizing:

Maybe stores simply don’t have enough people to pick, pack, and ship online orders, so they’re kicking them back, hoping another store can pick up the slack.

Perhaps inventory is not being properly shelved and arranged. (It turns out the store that had the least rejections was the flagship store next to PacSun’s HQ, which gets a lot of executive visits and runs a tight ship.)

It could be that inventory is going missing (i.e., being stolen), so there’s a mismatch between the inventory system quantities and actual on-hand quantities.

Determined to get to the bottom of this mystery, we brought in researchers from a top university to run a simulation for inventory accuracy. We figured this to be the best next step as it would help us determine how far off each store was from its fulfillment rate target and the fraction of time for rejections.

Expecting the rejections to be fully explained by high inventory inaccuracy rates – physical inventory is only conducted once a year, after all, and months had already passed since the last count – we were surprised that it could only explain about half the rejections! That meant that something was happening at the staffing level. The inventory is there, ready to be pulled and packed. But for some reason, associates are not responding to the incoming orders.

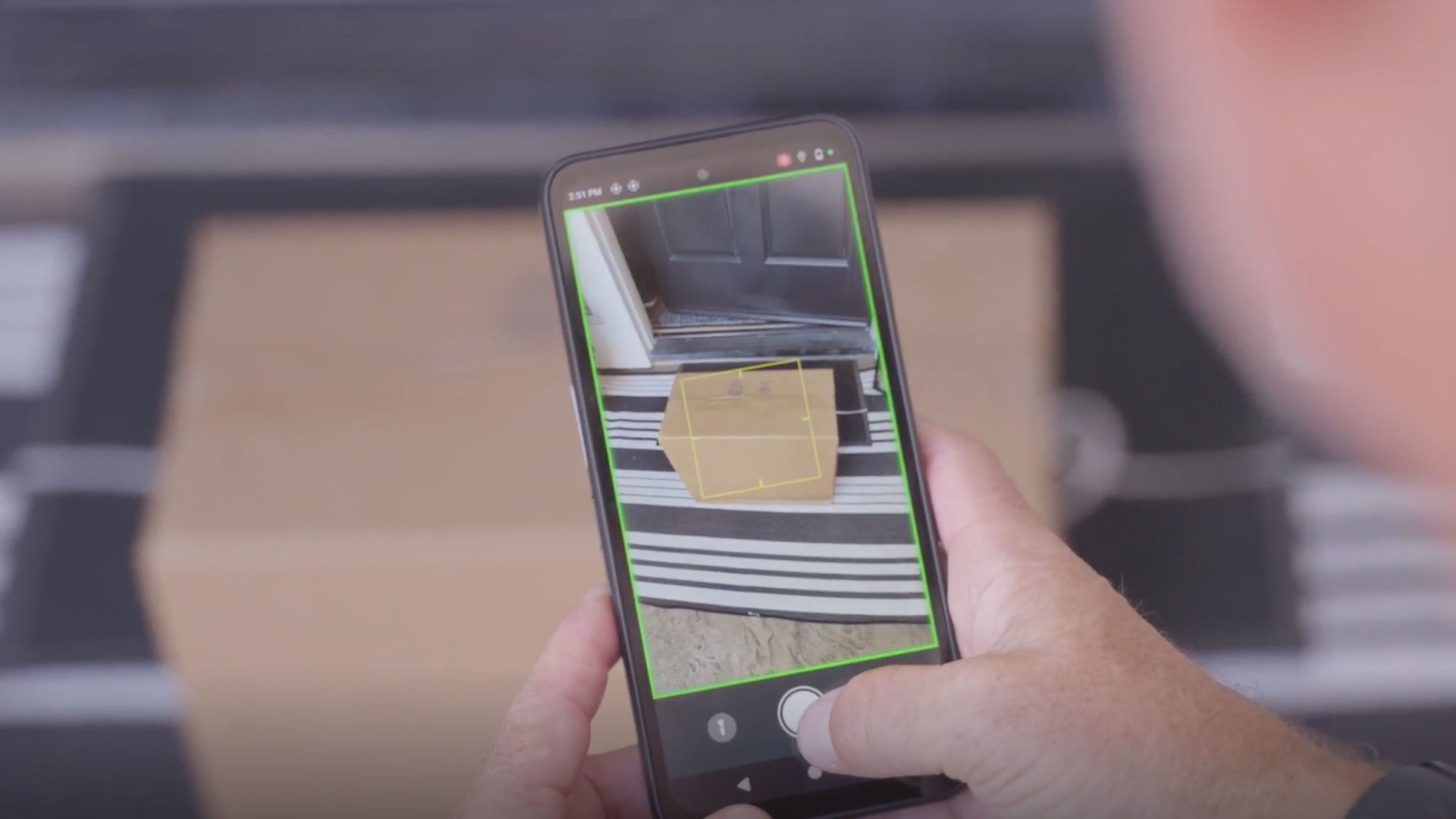

That’s when we started considering other investigative measures, to include the use of RFID technology. If PacSun (or any retailer) tagged all items in stores and gave staff handheld RFID readers (or added RFID sleds to the mobile computers they already use), then store associates could easily…

Conduct daily/weekly cycle counts if needed to confirm inventory on hand and improve inventory accuracy.

Locate misplaced inventory or confirm that items are indeed missing and system/on-hand quantities are mismatched.

Identify POS bypass attempts and have loss prevention teams intervene to keep inventory from going missing.

Just as important, RFID technology could help store managers – or headquarters staff – hold associates accountable. (You can’t say you can’t find an item when you have a fast way to do so. It will become obvious which associates put forth the effort and which ones don’t. And if you realize there are items walking out, but they don’t seem to be bypassing the POS in a traditional theft manner, then you can start to conduct an outlier analysis to see if you have losses stemming from insider fraud schemes.)

That’s why PacSun is expanding its use of the technology.

“Based on the findings, Pacsun has started an RFID initiative to get our inventory and fulfillment challenges under control,” Mike Relich, Pacsun Board Member and former CEO, recently confirmed.

In other words, if you’re having problems getting complete e-commerce orders out in a single shipment from stores, start by looking at your inventory placement and availability. But don’t stop there. Otherwise, you’ll never know if it truly is an inventory problem or if it’s an inventory and people problem.

The More You Know

Reach out to me and the antuit.ai/Zebra team if you’d like to hear more about…

how the simulation was designed/conducted for PacSun

the way we built and integrated the algorithms for PacSun to improve demand forecasting and inventory placement

the different ways RFID is being used by retailers to identify – and solve for – people problems along with inventory problems

We’ll be happy to share the data we have permission to share, along with our key learnings and recommendations. We know that this data, though specific to other retailers, will still help you tremendously as you figure out your best next move, whether you’re trying to find or fix a problem. Plus, it will give us a baseline from which to build a plan of attack for your biggest pain points.

###

Editor’s Note:

Want to learn more about how PacSun is using RFID? Mike Relich will be sharing the retailer’s story in two NRF sessions:

Explore the next frontier of AI-powered retail analytics: A cross-industry discussion

January 15, 9:15 am–10:00 am (Expo, Level 1, Expo Stage 2)

RFID unleashed: Levi's & PacSun's bold vision for the future of retail

January 16, 11:30 am–12:30 pm (Expo, Level 3, Expo Stage 4)

Kaushik Katari, Senior Director, CTO Solution Innovation, Zebra Technologies

Kaushik Katari served as the Chief Product Officer at antuit.ai before Zebra’s acquisition of antuit.ai. Prior to antuit.ai, he was the founder of Forecast Horizon and held various data-focused software product leadership roles.

![[Category, Subcat or Product] Representational Image 16:9](/content/dam/zebra_dam/global/zcom-web-production/web-production-photography/newsroom/2026-images/photography-web-newsroom-featured-03-16x9-en-us-013026.jpg.imgo.jpg)