Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimize workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Learn how Zebra's public sector technology solutions empower state and local governments to improve efficiency with asset tracking and data capture devices.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

Zebra's range of Banking technology solutions enables banks to minimize costs and to increase revenue throughout their branch network. Learn more.

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Adapt to market shifts, enhance worker productivity and secure long-term growth with AMRs. Deploy, redeploy and optimize autonomous mobile robots with ease.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customize your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Zebra's location technologies provide real-time tracking for your organization to better manage and optimize your critical assets and create more efficient workflows.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

Boost productivity with Zebra Frontline AI Enablers: AI vision models, sample apps, and APIs streamline workflows for efficient business processes.

Zebra Frontline AI Blueprints deliver adaptable, real-world AI frameworks that automate manual tasks and drive efficiency in high-pressure frontline operations.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labor costs low, your talent happy and your organization compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximizing IT resources and minimizing down time.

Make the most of every stage of your scanning journey from deployment to optimization. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

Boost warehouse and manufacturing operations with Symmetry, an AMR software for fleet management of Autonomous Mobile Robots and streamlined automation workflows.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customization starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximize productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

The Zebra Knowledge Center provides learning expertise that can be tailored to meet the specific needs of your environment.

Zebra has a wide variety of courses to train you and your staff, ranging from scheduled sessions to remote offerings as well as custom tailored to your specific needs.

Build your reputation with Zebra's certification offerings. Zebra offers a variety of options that can help you progress your career path forward.

Build your reputation with Zebra's certification offerings. Zebra offers a variety of options that can help you progress your career path forward.

How a Secret Wire Tracked a Pair of Jeans Around the World

An RFID thread connected to the right frequency makes it easy for manufacturers to relay critical intel on garments to retailers and shoppers.

I am standing outside a fashion store called Nobody's Child, a light and airy clothes shop in trendy Covent Garden, London, a stone's throw from the tube station. If I listen hard, I can hear trains rumbling quietly through the walls. Ladies’ garments in vibrant spring colours adorn the rails. Some plain, others with stylish floral designs, a large image of a young model wearing the latest collection in a sunlit lush meadow hangs from the wall. My eyes are drawn to a dark navy mid length dress with tiny yellow flowers that is figure flattering and exudes femininity. I brush the soft fabric and lift it from the rail, gazing at it in different directions to check the size and the cut.

But I'm not actually here shopping.

I am playing the role of a shopper in a video we are filming about ‘the life of a pair of jeans.’

Why?

We want to illustrate how Nobody's Child and its partners are meeting a European Union (EU) initiative just over the horizon: Digital Product Passports (DPPs).

Textiles are just one of an initial 13 product sectors which will eventually grow to 30 categories by 2030 that will require DPPs under the new rules forming part of the EU’s Green Deal. Gradual mandatory implementation of DPPs will begin in 2027. Exact requirements are still being defined, with stakeholders actively deliberating at a European level. But the concept looks set to become a reality, and the clock is ticking.

Which is why we are here.

Movie making with a purpose.

Our goal is to show others how they might support these circular economy and sustainability objectives.

A Single Thread

The star of our (3-minute) movie is Andrew Xeni, CEO of Nobody's Child and Fabacus, a data company that holds the DPP data behind the scenes in its platform called Xelacore, which aligns with the regulatory framework.

Nobody's Child is both leading the charge for others and doing things innovatively in house. It has been a proving ground for its own products, including a passport it created for its clothing (ahead of the curve) which links to QR codes in wash labels.

But now it has a clever extra. Behind the 'seams' is a secretive bit of technology that silently proves authentication. A radio frequency identification (RFID) thread that links each garment to a unique passport.

You are no doubt familiar with RFID labels on make-up, for example, which activate alarms as a loss prevention measure.

This may well be your solution.

The best part is the RFID tracker sewn into jeans uses the same tech but in a thin thread of wire, just 5cm long or thereabouts. It’s hidden in the clothing but activated by an RFID reader – be that handheld, fixed, in a point of sale (POS) mat, as part of a kiosk, or inside a mobile computer.

Our video is a simple story of a pair of jeans that begins at manufacture.

To create the visuals, we visited the Xeni family's London factory/design and distribution hub. I got to see industrial sewing machines, colourful fabrics, and inspirations from catwalks pinned to the walls. A hub of creativity. And our star seamstress was none other than Andrew's mum. Mrs. Xeni showed us how an RFID thread is sewn into the hem of a garment. It was a privilege to meet a business lady who once distributed a million items in just one week from this London address.

Business is very much part of the Xeni family DNA, and its reach is far.

The real jeans are manufactured in Morocco. Andrew tells me this was an epicentre of production for his family of entrepreneurs who, in their heyday, produced 600,000 garments a week for a huge variety of fashion brands.

What's different is this pair of jeans has a QR code that links to its passport. This will allow consumers to access info about the jeans with their mobile phone cameras.

But it also has its encoded wire – an RFID label in a long thread, not a sticky label. If you fire the right frequency of radio waves, it responds with a URL weblink or number, much like a barcode would. That number is its identifier, the master key that links it to its passport. This identifier allows systems to access key data points from the passport, needed to track its location and understand the composition of the product, so its handled accordingly when recycled.

This drives significant speed and efficiency, making circularity and recycling easier for large volumes. The RFID thread enables activities to be done fast and at high volume – great for Nobody’s Child or any busy retailer, and it alleviates issues with fraud. Copying a wash label with a QR code attached is doable. Copying a piece of hidden wire to ensure its encoded with the correct unique number is considerably more challenging.

Stamping the Passport

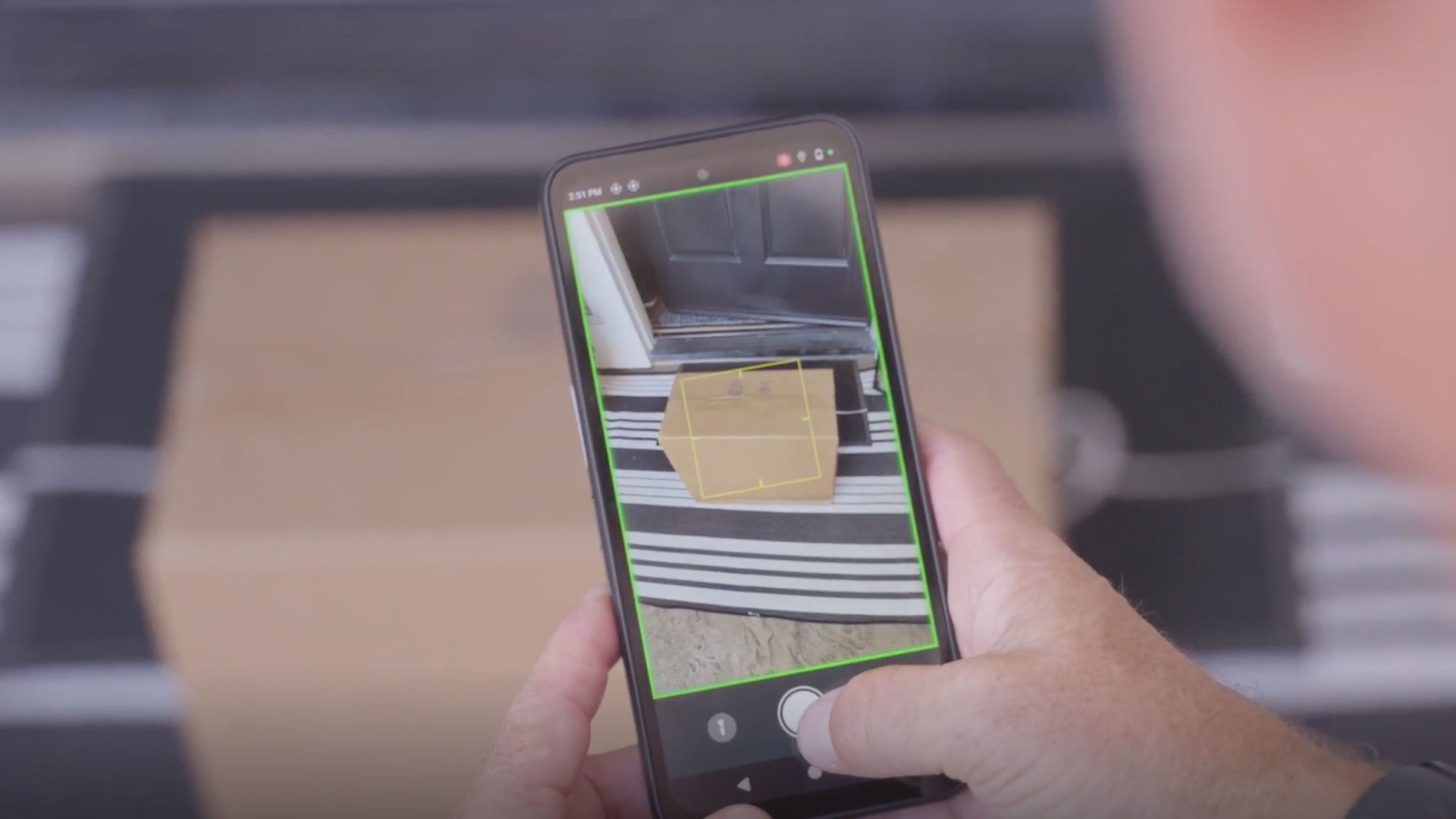

In our micro movie, the Nobody's Child jeans arrive at the store by a local courier and are checked in using an RFID reader. The reader, inbuilt with superhero powers, sees through walls – in this case, the walls of the cardboard box. It does a stock take of the garments inside the box while date stamping garments against their passports in the same way a stern official might stamp our documents at passport control as we traverse the world.

Once the jeans hit the shelves, our shopper spots them and uses their own phone to access the passport to see where they were made, what they were made from, and a whole lot more, including any environmental impact information such as CO2 and water usage. The store also has a gigantic kiosk to let shoppers access the info in glorious technicolour detail.

In this case, it’s a straightforward return - which we film back in-store. But the interesting piece of the puzzle is the RFID inside. No receipt is required; genuineness is guaranteed.

Jump forward again to a real purchase and a couple of resales.

Our eco-buyers are avid re-users. Imagine the jeans have become threadbare around the knees after a period spent crawling about with babies as they grew into toddlers. There is a spaghetti-based stain that won't shift and another from a particularly fun muddy day. The jeans are only fit for memories, and it's time for them to be recycled into something fresh. Our shopper brings them back to the store, and Nobody’s Child manages the recycling.

The final step might be at a clothing recycler where the clever piece of hidden tech – the RFID thread – becomes important again. A quick scan and the final date stamp goes to its DPP. The garment’s content and colour are noted, and it’s retired to a skip with equivalent articles so it can be broken down and rebuilt to create something new. Circularity in motion. The data flows to the EU data centre, and the overall carbon footprint is noted and added to a billion other entries.

And whatever comes next begins its lifecycle. Check out this video to learn more.

What to Do with This Intel

At Nobody’s Child, I thank Andrew Xeni for letting me into his inner world. His journey from manufacturer to launching a highly successful sustainable fashion brand and then building a software company that provides a practical solution to the fast-approaching EU legislation (while building bonds with the right technology industry experts) was both inspirational and enlightening.

He wants others to benefit from his experiences. So, as you consider how you will deliver Digital Product Passports for your merchandise, it’s worth considering how you will connect the product to the digital world.

QR codes work for consumers as it’s one person looking at one item.

But as a manufacturer, seller or a recycler, RFID is a great hidden marker for:

- Stocktaking

- Weeding out fraud

- Enabling efficient recycling

- Running competitions

- Generating brand experiences.

The use cases are limited only by your imagination.

Plus, there is so much more to consider.

1. How do you create an attractive interface that consumers connect with?

2. What tech do you use to connect the dots?

3. How do you ensure interoperability between stakeholders?

We've thought about it a lot, and we've started building things that work, together.

If you'd like our collective help, then now is the time to get in touch.

Why This Matters to You, Me, and Everyone Around Us

There are three impacts here:

1. Putting sustainability data on a garment’s digital record makes it accessible to a wide raft of stakeholders. Manufacturers, transporters, retailers, shoppers, recyclers, EU auditors, and everyone in between can log and follow the data trail essential for sustainability monitoring and reporting.

2. DPPs will change the way we shop by allowing shoppers to see exactly where their garment originated from, what it's made from, and its carbon footprint. Sustainability orientated buyers can make sure their purchases align with their values. At purchase, be that first buy or at re-use.

3. While DPPs provide data points for ethical decision-making matter, the core purpose is to give visibility of a product's environmental footprint to the EU. This will provide the proof that it is meeting its bold Green Deal goal: to achieve net-zero carbon emissions by 2050.

Zebra Developer Blog

Zebra Developer BlogZebra Developer Blog

Are you a Zebra Developer? Find more technical discussions on our Developer Portal blog.

Zebra Story Hub

Zebra Story HubZebra Story Hub

Looking for more expert insights? Visit the Zebra Story Hub for more interviews, news, and industry trend analysis.

Search the Blog

Search the BlogSearch the Blog

Use the below link to search all of our blog posts.

Most Recent

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. Note: Some content or images on zebra.com may have been generated in whole or in part by AI. ©2026 Zebra Technologies Corp. and/or its affiliates.

![[Category, Subcat or Product] Representational Image 16:9](/content/dam/zebra_dam/global/zcom-web-production/web-production-photography/newsroom/2026-images/photography-web-newsroom-featured-03-16x9-en-us-013026.jpg.imgo.jpg)