Transform retail operations with Zebra’s retail technology solutions, featuring hardware and software for improving inventory management and empowering teams.

Streamline operations with Zebra’s healthcare technology solutions, featuring hardware and software to improve staff collaboration and optimize workflows.

Enhance processes with Zebra’s manufacturing technology solutions, featuring hardware and software for automation, data analysis, and factory connectivity.

Zebra’s transportation and logistics technology solutions feature hardware and software for enhancing route planning, visibility, and automating processes.

Learn how Zebra's public sector technology solutions empower state and local governments to improve efficiency with asset tracking and data capture devices.

Zebra's hospitality technology solutions equip your hotel and restaurant staff to deliver superior customer and guest service through inventory tracking and more.

Zebra's market-leading solutions and products improve customer satisfaction with a lower cost per interaction by keeping service representatives connected with colleagues, customers, management and the tools they use to satisfy customers across the supply chain.

Empower your field workers with purpose-driven mobile technology solutions to help them capture and share critical data in any environment.

Zebra's range of Banking technology solutions enables banks to minimize costs and to increase revenue throughout their branch network. Learn more.

Zebra's range of mobile computers equip your workforce with the devices they need from handhelds and tablets to wearables and vehicle-mounted computers.

Zebra's desktop, mobile, industrial, and portable printers for barcode labels, receipts, RFID tags and cards give you smarter ways to track and manage assets.

Zebra's 1D and 2D corded and cordless barcode scanners anticipate any scanning challenge in a variety of environments, whether retail, healthcare, T&L or manufacturing.

Zebra's extensive range of RAIN RFID readers, antennas, and printers give you consistent and accurate tracking.

Choose Zebra's reliable barcode, RFID and card supplies carefully selected to ensure high performance, print quality, durability and readability.

Zebra's rugged tablets and 2-in-1 laptops are thin and lightweight, yet rugged to work wherever you do on familiar and easy-to-use Windows or Android OS.

With Zebra's family of fixed industrial scanners and machine vision technologies, you can tailor your solutions to your environment and applications.

Zebra’s line of kiosks can meet any self-service or digital signage need, from checking prices and stock on an in-aisle store kiosk to fully-featured kiosks that can be deployed on the wall, counter, desktop or floor in a retail store, hotel, airport check-in gate, physician’s office, local government office and more.

Adapt to market shifts, enhance worker productivity and secure long-term growth with AMRs. Deploy, redeploy and optimize autonomous mobile robots with ease.

Discover Zebra’s range of accessories from chargers, communication cables to cases to help you customize your mobile device for optimal efficiency.

Zebra's environmental sensors monitor temperature-sensitive products, offering data insights on environmental conditions across industry applications.

Zebra's location technologies provide real-time tracking for your organization to better manage and optimize your critical assets and create more efficient workflows.

Enhance frontline operations with Zebra’s AI software solutions, which optimize workflows, streamline processes, and simplify tasks for improved business outcomes.

Empower your frontline with Zebra Companion AI, offering instant, tailored insights and support to streamline operations and enhance productivity.

Boost productivity with Zebra Frontline AI Enablers: AI vision models, sample apps, and APIs streamline workflows for efficient business processes.

Zebra Frontline AI Blueprints deliver adaptable, real-world AI frameworks that automate manual tasks and drive efficiency in high-pressure frontline operations.

Zebra Workcloud, enterprise software solutions boost efficiency, cut costs, improve inventory management, simplify communication and optimize resources.

Keep labor costs low, your talent happy and your organization compliant. Create an agile operation that can navigate unexpected schedule changes and customer demand to drive sales, satisfy customers and improve your bottom line.

Drive successful enterprise collaboration with prioritized task notifications and improved communication capabilities for easier team collaboration.

Get full visibility of your inventory and automatically pinpoint leaks across all channels.

Reduce uncertainty when you anticipate market volatility. Predict, plan and stay agile to align inventory with shifting demand.

Drive down costs while driving up employee, security, and network performance with software designed to enhance Zebra's wireless infrastructure and mobile solutions.

Explore Zebra’s printer software to integrate, manage and monitor printers easily, maximizing IT resources and minimizing down time.

Make the most of every stage of your scanning journey from deployment to optimization. Zebra's barcode scanner software lets you keep devices current and adapt them to your business needs for a stronger ROI across the full lifecycle.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

RFID development, demonstration and production software and utilities help you build and manage your RFID deployments more efficiently.

Zebra DNA is the industry’s broadest suite of enterprise software that delivers an ideal experience for all during the entire lifetime of every Zebra device.

Advance your digital transformation and execute your strategic plans with the help of the right location and tracking technology.

Boost warehouse and manufacturing operations with Symmetry, an AMR software for fleet management of Autonomous Mobile Robots and streamlined automation workflows.

The Zebra Aurora suite of machine vision software enables users to solve their track-and-trace, vision inspection and industrial automation needs.

Zebra Aurora Focus brings a new level of simplicity to controlling enterprise-wide manufacturing and logistics automation solutions. With this powerful interface, it’s easy to set up, deploy and run Zebra’s Fixed Industrial Scanners and Machine Vision Smart Cameras, eliminating the need for different tools and reducing training and deployment time.

Aurora Imaging Library™, formerly Matrox Imaging Library, machine-vision software development kit (SDK) has a deep collection of tools for image capture, processing, analysis, annotation, display, and archiving. Code-level customization starts here.

Aurora Design Assistant™, formerly Matrox Design Assistant, integrated development environment (IDE) is a flowchart-based platform for building machine vision applications, with templates to speed up development and bring solutions online quicker.

Designed for experienced programmers proficient in vision applications, Aurora Vision Library provides the same sophisticated functionality as our Aurora Vision Studio software but presented in programming language.

Aurora Vision Studio, an image processing software for machine & computer vision engineers, allows quick creation, integration & monitoring of powerful OEM vision applications.

Adding innovative tech is critical to your success, but it can be complex and disruptive. Professional Services help you accelerate adoption, and maximize productivity without affecting your workflows, business processes and finances.

Zebra's Managed Service delivers worry-free device management to ensure ultimate uptime for your Zebra Mobile Computers and Printers via dedicated experts.

Find ways you can contact Zebra Technologies’ Support, including Email and Chat, ask a technical question or initiate a Repair Request.

Zebra's Circular Economy Program helps you manage today’s challenges and plan for tomorrow with smart solutions that are good for your budget and the environment.

The Zebra Knowledge Center provides learning expertise that can be tailored to meet the specific needs of your environment.

Zebra has a wide variety of courses to train you and your staff, ranging from scheduled sessions to remote offerings as well as custom tailored to your specific needs.

Build your reputation with Zebra's certification offerings. Zebra offers a variety of options that can help you progress your career path forward.

Build your reputation with Zebra's certification offerings. Zebra offers a variety of options that can help you progress your career path forward.

How Do You Track a Crutch When It Leaves the Hospital?

It’s a Monday morning, and I am in a busy Accident & Emergency (A&E) facility at my local hospital. A young boy in a school uniform nurses a sore wrist and a workman wearing a high visibility jacket leans back in a wheelchair amidst a sea of injured humans. It reminds me of being at the vets as I guess at ailments, yet no cute puppies to lighten the air. My stepson is with me with an angry looking knee - twice the size it should be. An overly zealous rugby tackle, the cause of his discomfort.

We are to my surprise seen very quickly by a doctor who squeezes and manipulates the injury to winces of pain from the afflicted one. Some questions about the circumstances. The fact he continued the game seems to seal the deal - there are no breakages. Pamphlet printed, crutch signed over and advice against sport for six weeks floats into one of the patient's ears and immediately out of the other.

As we head for the exit, I ask a nurse how and when we should return the crutch. She looks at me a little puzzled then replies that we should just keep it.

As we head home, I reflect on the stockpile of medical aids in my stepchildren's rooms, all linked to sporting injury - another crutch, a boot, a wrist support. I consider the huge volumes of unused medical equipment that must be left in the back of closets all over the world. It strikes me as wasteful. Hospitals are working so hard to better use assets within their buildings, so why has this mindset not infiltrated device movement off premises? What happens to assets once they leave healthcare locations and why are low value items being written off?

RFID Provides Instant Visibility

Hull University Teaching Hospitals NHS Trust, like many others, was losing hours of clinician time as it looked for misplaced medical equipment, and it was often replacing things unnecessarily when they couldn't be found. The group recognised the inefficiency and implemented an RFID-based asset tracking system that now provides instant visibility of around 72,000 assets throughout the hospital. If personnel need something, they simply look for it and the RFID tag shows where it is located. The system is pioneering globally, but theirs, like many other systems, stops at the hospital doors.

Hospitals often loan each other expensive devices, sterile trays and products such as surgical implants. Yet there may not be reliable mechanisms in place to monitor the whereabouts of products after they have left site. Sharing surgical implants between hospitals is fairly common. A nearby hospital might lend an implant such as a hip or a knee for a surgery bottleneck with an expectation of a replacement product being returned or order of a new item being triggered and the cost billed and passed back. But things are easily overlooked as clinicians focus on the patient and their recovery. The lending hospital may have incorrect stock numbers as they assume a product remains on the shelf.

So rather than hazard a guess at what processes are, or as I suspect not in place, I decide to contact 12 large acute hospitals in the UK and ask them directly.

My Survey Results

My first question gets straight to the point. Do they have a formal digital system for tracking products sent to other hospitals? More than half of the eight respondents said they did not (five versus two that did and one nonapplicable). Without a mechanism to check things out, the likelihood of compensation or return drops as it relies on memory and prioritisation.

A simple inventory management process, scanning things in and out would overcome this. At a hospital like Hull where assets are already RFID tagged - the process could be automated. If the receiving hospital had RFID readers installed, even just at basic points like the loading bay or the dispatch area, it would be automatically received. Imagine the power of fully interoperable hospitals sharing materials based on supply and demand.

To check the issue was substantial enough, we asked the hospitals about product destinations. Those that were sharing kit were regularly doing it with up to six different, usually local facilities. The cadence was not monitored but ad hoc and when things were requested. So, a tremendous amount of goodwill is in place between facilities, but a lot of opportunity to lose track of where things have gone.

Only three of the hospitals I asked said they had a reliable mechanism for ensuring compliance, payment and expediting. One said they did, if the correct processing of items sent out and returned was completed, plus an additional manual process was undertaken to communicate with finance. It sounded complex and prone to human error.

I ended with my trigger question. The one that kicked off my thoughts when leaving my local A&E. Do they have a formal returns process for items given to the public (e.g. crutches)?

Four clear nos. Of the three hospitals that said they did have a formal process in place, one stood out. They had a walking aid recycling project. All walking aids were labelled for auditing and then inspected for safety and cleaned ready for reuse. Each return was registered and the data submitted to their sustainability team and NHS England.

So, from my investigations, I saw facets of excellence in the control of materials outside of the hospitals, but gaps and huge opportunities too. What should hospitals be doing to get visibility of assets as they leave their site? And what can be done to turn that knowledge into action that can stop things from disappearing and perhaps even maximise on a broader asset portfolio than one hospital alone?

Streamlining Care Across Clusters

With NHS England announcing a new management structure for hospitals, 26 Integrated Care System (ICS) clusters will now be created at the sub-regional level. These clusters will manage resources, funding, and patient numbers collectively. This new structure could provide a real opportunity to effectively manage lower-level resources, which, although less significant, remain valuable.

Where would we start with a process for managing assets out of the hospital? The first port of call would be to implement some type of formal process, or automation, to eradicate reliance on someone having to remember to do something. Even with the best will in the world, remembering is not foolproof.

I'm sure there are lots of my belongings dotted around the country that I have lent to friends and family and forgotten about or vice versa. In fact, this blog reminds me, I need to give my mum back her drill!! And aside from forgetting, in the case of my stepson returning a walking aid, there is currently nowhere to return the item at all.

Once a library book type system is in place, then the next most important element to ensure adoption, is to make it easy. And this is where it makes sense to build upon an existing process as we learnt at our recent RFID Forum. Read the blogs Part 1 and Part 2, a medical device company like Stryker uses RFID to locate items in its warehouses. The tags are present on items like its star product - a triathlete prosthetic knee. Watch the video.

If that knee is sold to and transported to a hospital like Hull, the hospital RFID infrastructure is in place to know exactly where the knee device is throughout its stay in the hospital. It is even visible after it leaves the hospital, embedded between someone's femur and tibia, by checking their Electronic Patient Record - essential in case of a product recall.

The missing links are hospital to hospital loans, and hospital to patient loans of lower value items. But the process replicates that of higher value items.

Close the Loop on Medical Asset Lifecycles

In an RFID-enabled hospital like Hull, assets are already assigned with a uniquely identifiable RFID tag. The tag links the asset to the hospital asset management database. The database holds all types of relevant info such as what it is, (e.g. wheelchair, commode, walker, crutch), which department owns it, status (e.g., available, in use, in repair), its location, and its maintenance status (e.g. requires servicing on specific date).

As the device moves within the hospital, RFID readers strategically placed at key points throughout the building, covering all entrances and exits for each clinical zone such as doorways between wards, storerooms, and at exits, automatically capture the tag's unique ID and send this data to the central database. As the system logs the new location of the device, it creates a real-time (or near real-time) audit trail. This helps hospital staff quickly locate equipment, reducing the time they spend searching for it. Staff can use handheld RFID scanners to check things in and out and track them down using beeps that get progressively closer as you get nearer the item.

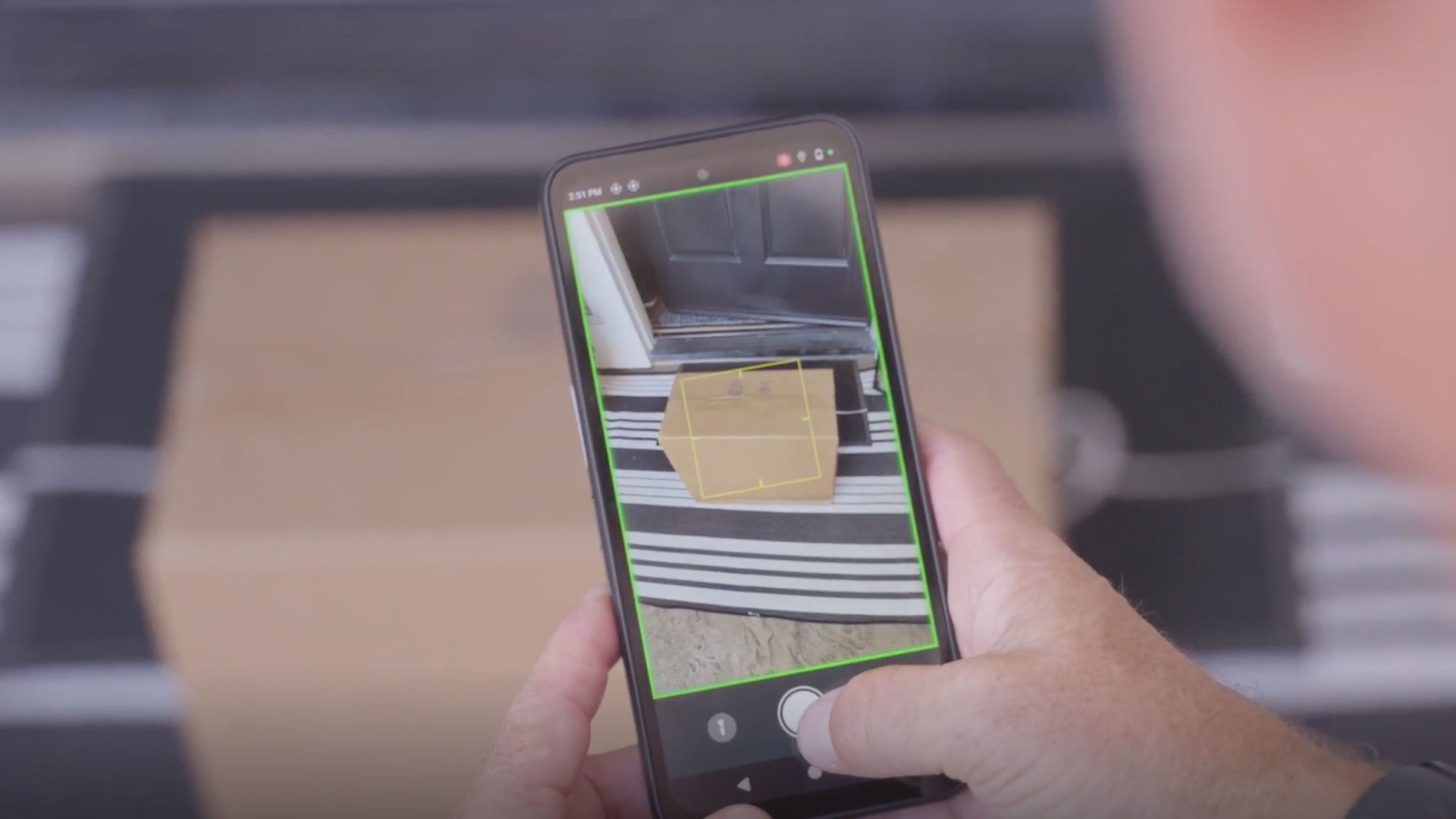

To extend this process beyond the hospital, when a patient is assigned a mobility device for use at home or another hospital borrows a surgical implant like a knee, the device is scanned and 'checked out' as it leaves the hospital. This scanning event is recorded in the central database, changing the device's status from "available" to "in use" and linking it to a specific patient's record or allocating it to a nearby hospital. The record will note the date and time of the transfer.

From Hospital to Home: RFID in Action

Outside the hospital, the tracking is now event-based. The system's primary function is to know when the device left the hospital and when it’s expected to be returned.

When the patient no longer needs the device or a hospital returns an asset, an RFID reader at the receiving point scans the device. The central database is automatically updated. The device's status is changed from "in use" to "in storage" or "awaiting cleaning/maintenance," and the link to the patient is closed. If the hospital pays for the device or replaces it, the database can be updated manually and the asset accounted for. This provides a complete record of the device's lifecycle, from issue to return.

The RFID system can also be integrated with the maintenance schedule. The system can trigger an alert that a device needs to be serviced, cleaned, or repaired after its return, ensuring it is in a safe and usable condition before being reissued.

The entire process provides a comprehensive, automated, and auditable chain of custody for medical assets. This increases resource availability, improves efficiency, reduces loss, and ensures patient safety by guaranteeing that devices are always properly maintained.

In summary, many assets are not being tracked as they leave hospitals. Implementing an RFID- based inventory management system can ensure assets are fully accounted for between facilities. It can also pave the way for better re-use of patient loans, improving efficiency, bolstering sustainability, releasing funds to enhance patient care, and of course, freeing up space in closets by re-using the millions of mobility aids tidied away and forgotten about all over the world.

Zebra Developer Blog

Zebra Developer BlogZebra Developer Blog

Are you a Zebra Developer? Find more technical discussions on our Developer Portal blog.

Zebra Story Hub

Zebra Story HubZebra Story Hub

Looking for more expert insights? Visit the Zebra Story Hub for more interviews, news, and industry trend analysis.

Search the Blog

Search the BlogSearch the Blog

Use the below link to search all of our blog posts.

Most Recent

Legal Terms of Use Privacy Policy Supply Chain Transparency

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners. Note: Some content or images on zebra.com may have been generated in whole or in part by AI. ©2026 Zebra Technologies Corp. and/or its affiliates.