Confidently measure wafer notch position using 2D imaging and 3D validation for faster lines and improved yield

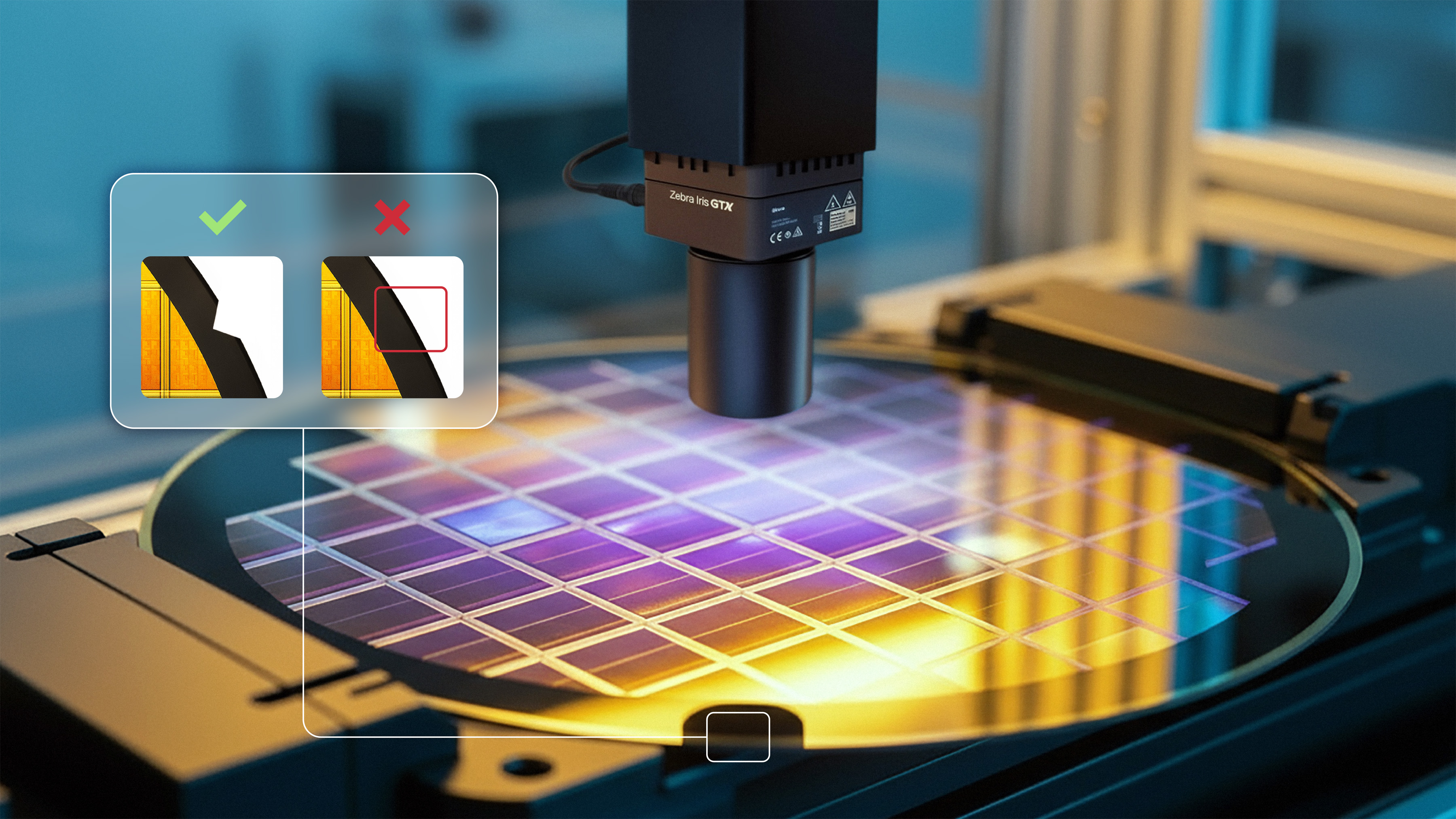

Measure wafer notch position with precision

Zebra smart cameras capture high-resolution images of the wafer’s edges and notches. These images are analyzed using Aurora machine vision software. After calibrating the optics once, the software converts the pixel distances into micrometers. It then matches arcs, lines, and circle centers to the wafer’s edge to determine the notch’s angle and offset, checking these against user-defined tolerances. If there’s any misalignment, a correction to adjust the wafer can be made before the next step, ensuring it stays precisely aligned.

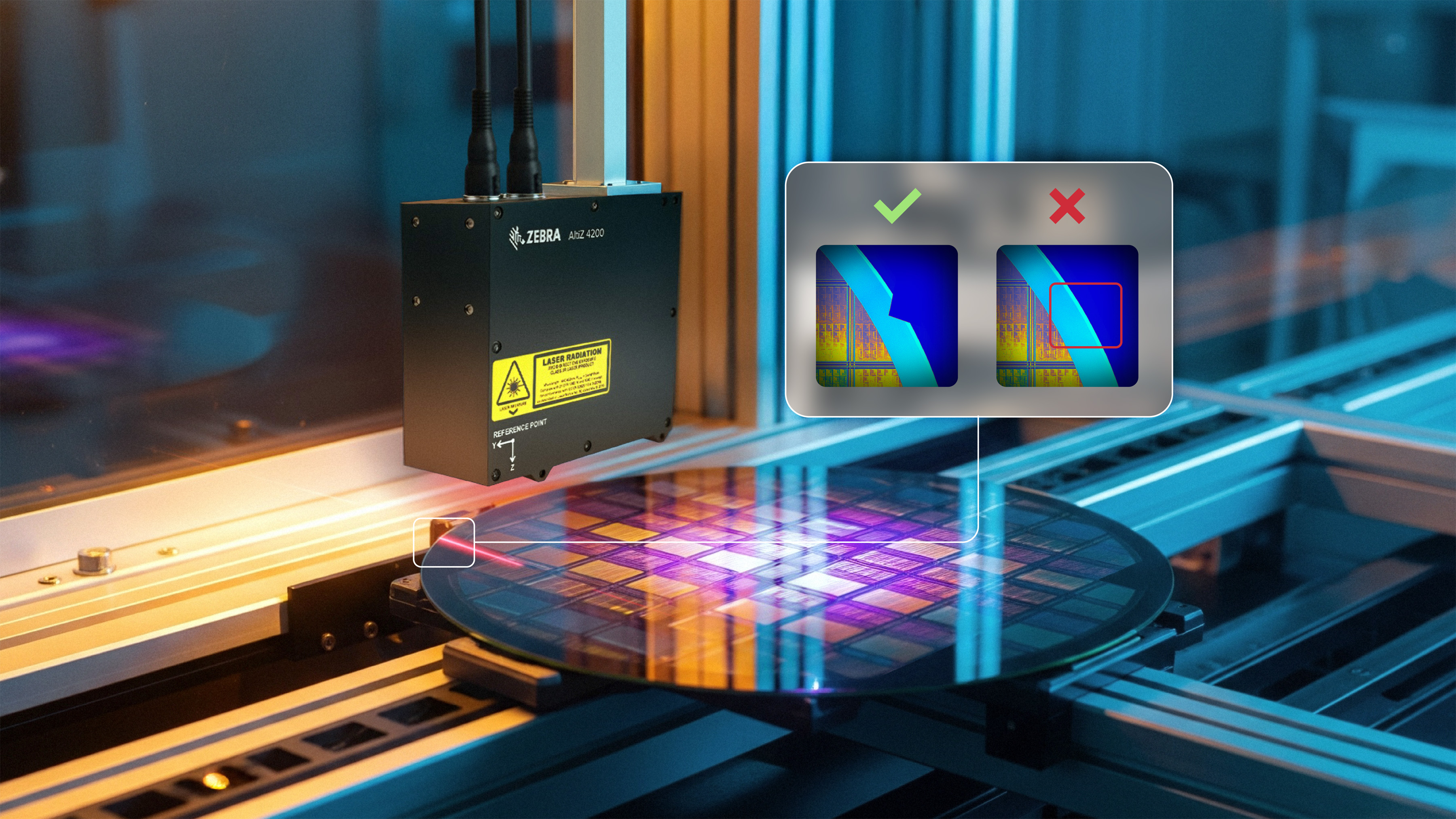

Add 3D validation for in‑motion accuracy

AltiZ 3D profile sensors capture three‑dimensional (3D) point clouds of the wafer edge and notch while conveyors move, verifying the wafer’s position, tilt, and bow without stopping the line. The system cross-checks 2D measurements with 3D geometry to prevent errors from glare, automatically adjusting robot handling or raising alarms as needed. It effectively manages glossy surfaces and maintains alignment at typical production speeds.

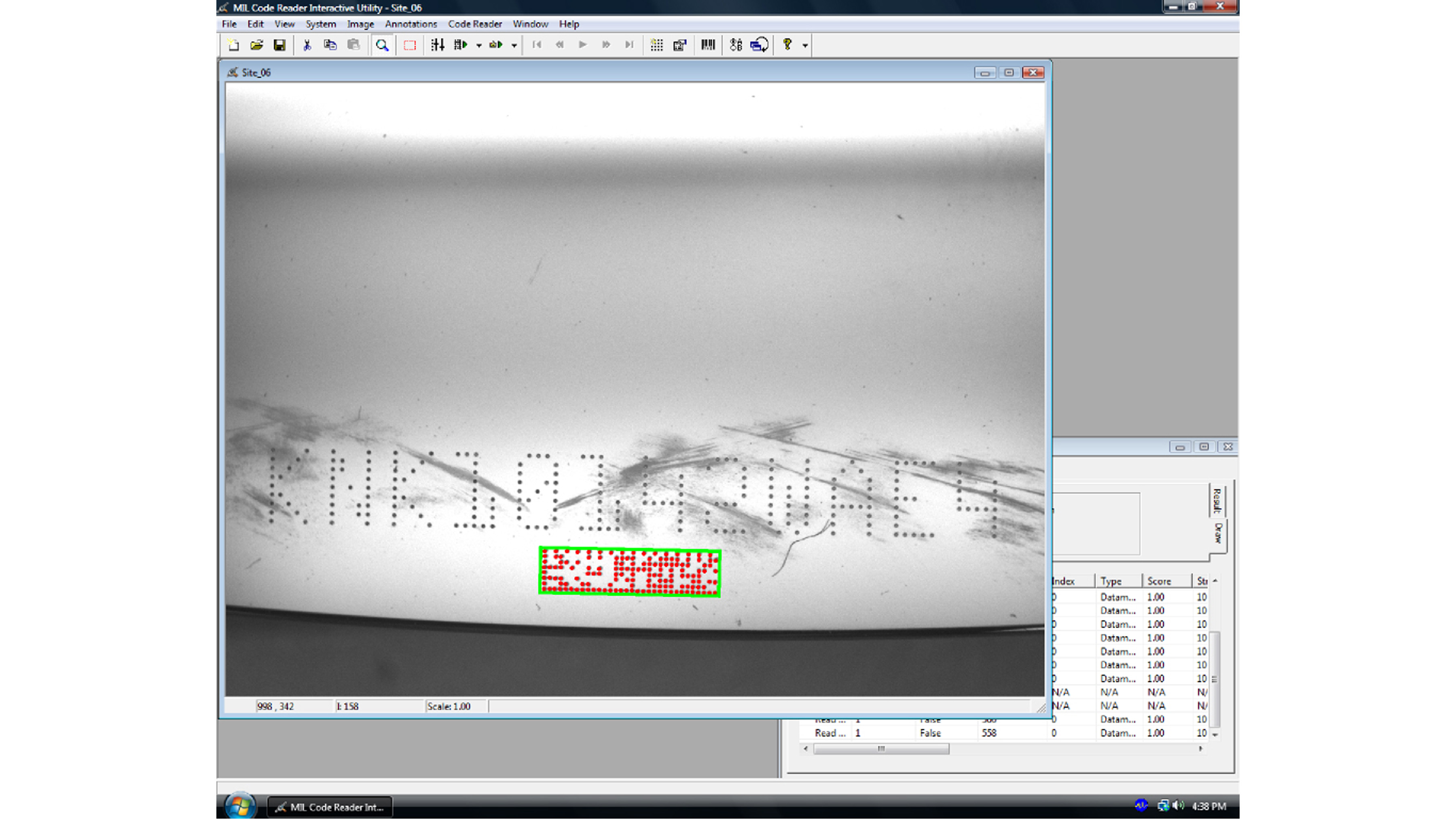

Turn Inspection Data into Process Control and Traceability

The Zebra Aurora software platform makes it easy to share alignment results directly with a Manufacturing Execution System (MES) and statistical process control (SPC) dashboards. Aurora Imaging Library software captures precise measurements of wafer positions. Each measurement is carefully tagged with information like lot, tool, and recipe IDs, making audits traceable and allowing for strong trend analysis. This all-in-one solution ensures that wafers meet strict quality standards, automatically flags out-of-spec positions, and keeps a detailed record of any adjustments made.

Related Use Cases

Fixed Industrial Scanning and Machine Vision Success Stories

Talk to a Partner

Need more information on what solution is right for your needs? A partner can help.

Talk to Sales

Connect with our pre-sales team to get more information about our products, solutions and how to purchase.